A research group from the Center for Physical Sciences and Technology (FTMC, Lithuania), together with partners from Tallinn University of Technology (Estonia) set out to synthesize new material that could potentially complement silicon solar cell technologies and increase the overall efficiency of solar modules.

Increased energy prices resulted in a rapid growth of the renewable energy sector. With progressively increasing deployment of solar parks, improvement of solar panel efficiency is an essential development step to produce more power from the same area.

The best solar cell technologies found on rooftops can convert only a quarter of the total sun’s energy to electricity. Solar cell efficiency can be enhanced by joining different technologies together to create a device known as a multijunction solar cell.

On the theoretical level, such a device can convert almost half of solar energy to electricity. However, multi-junction solar cell technologies are more complicated in terms of production, requiring the adoption of novel materials and processes at the same time keeping the cost and sustainability aspects in mind.

The team’s research is focused on semiconductors with a chemical structure that is typical to perovskite materials—ABX3 but instead of oxygen or halogens, they explore compounds where X is sulfur/selenium and A and B are abundant and non-toxic metals. The work has been published in Journal of Materials Chemistry A.

Using a solid-state reaction method researchers synthesized new material—tin zirconium titanium selenide—for the first time and discovered that Sn(ZrxTi1-x)Se3 alloy was the most promising for photovoltaic application.

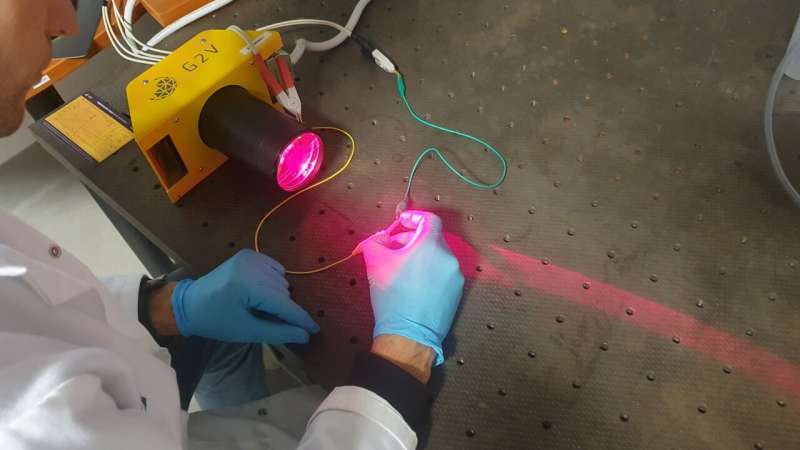

Experiments with new material. © Center for Physical Sciences and Technology

“Under current geopolitical situation in Europe and environmental concerns, it is important that novel materials that are being explored and considered for renewable energy application are composed of abundant elements and free of critical raw materials,” states the leading author of the study, Dr. Rokas Kondrotas, head of the Department of Characterization of Materials Structure at FTMC, Lithuania.

The group found that introducing titanium with a concentration of up to 44%, did not change the crystalline structure of Sn(ZrxTi1-x)Se3 alloy, however, it had a profound effect on both optical and electrical material’s properties.

The higher the concentration of titanium, the more the absorption edge of Sn(ZrxTi1-x)Se3 shifted towards the short-wavelength infrared spectrum region. This part of the infrared spectrum coming from the sun, is not absorbed by conventional crystalline silicon solar cell and therefore is lost.

Sn(ZrxTi1-x)Se3 semiconductors synthesized with high titanium concentration, can absorb short-wavelength infrared light and convert it into extra energy boosting the overall Si-based multi-junction device efficiency.

In addition, the authors found that introducing titanium in the Sn(ZrxTi1-x)Se3 alloys significantly enhanced the absorption coefficient. Materials with high absorption coefficient are desirable for solar cells, because even a very thin layer, 20 times thinner than the strand of hair, is enough to absorb all the incoming light from the sun.

This work is the first step for the development of novel sustainable materials with a high potential for multi-junction solar cell application in the infrared region. The next milestone of this technology is the synthesis of Sn(ZrxTi1-x)Se3 thin film, allowing for fabrication and testing of the solar device.

More information:

Rokas Kondrotas et al, Band gap engineering by cationic substitution in Sn(Zr1−xTix)Se3 alloy for bottom sub-cell application in solar cells, Journal of Materials Chemistry A (2023). DOI: 10.1039/D3TA05550G

Provided by

Center for Physical Sciences and Technology

Citation:

New material to boost the efficiency limits of silicon solar cells (2024, January 8)