In a new report in NPG Asia materials, Chisa Norioka and a team of scientists in Chemistry and Materials Engineering in Japan, detailed a universal method to easily prepare tough and stretchable hydrogels without special structures or complications. They tuned the polymerization conditions to form networks with many polymer chain entanglements, to achieve energy dissipation throughout the resulting materials. The team prepared the tough and stretchable hydrogels via free radical polymerization using a high monomer concentration and low crosslinker content to optimize the balance between physical and chemical crosslinks via entanglements and covalent bonds. The research team used polymer chain entanglements for energy dissipation to overcome the limits of low mechanical performance for use in a wide-range of hydrogels.

Hydrogels

Hydrogels consist of physically and chemically crosslinked polymer networks and a high-water content with a low elastic modulus for stimulus-responsive behavior, much like biological tissues. As a result, hydrogels have potential applications as biomaterials for drug delivery systems, biosensors and cell culture. While hydrogels are soft and flexible, they are also weak and brittle, where standard hydrogels can be broken due to large deformation. To overcome the low mechanical properties of hydrogels, researchers had designed network structures. Hydrogels exhibit viscoelastic behavior for both viscous and elastic characteristics, to design tough hydrogels therefore Norioka et al. focused on the viscous characteristics. Viscosity allowed the applied stress to be relaxed through energy dissipation. The researchers produced hydrogel networks with a high polymer chain density, with large molecular weight between crosslinkers for effective energy dissipation throughout the material. During the experiments they added high monomer concentrations and low cross-linker content to form hydrogel networks with many entanglements to produce the physical crosslinks. To demonstrate the strategy, Norioka et al. used polyacrylamide (PAAm) and poly(2-methacryloyloxyethyl phosphorylcholine) (PMPC) as the main chains of the hydrogels.

Materials characterization

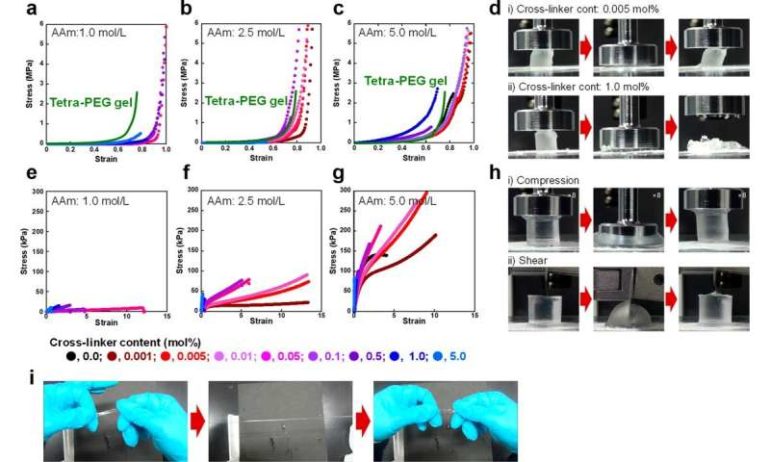

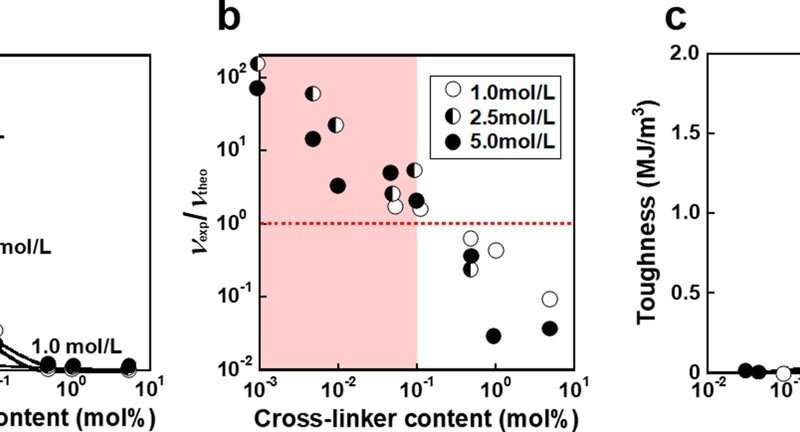

The team tested the mechanical properties of the as-prepared PAAm hydrogels using compression and tensile tests. They noted the inhomogeneous PAAm hydrogels formed under polymerization conditions, containing a high monomer concentration and low crosslinker content to be tougher than those with a homogeneous network structure. Similarly, swollen PAAm hydrogels with a high monomer concentration and low-crosslinker content also demonstrated high mechanical toughness and high stretchability. Using stress-strain curves during tensile tests, Norioka et al. investigated the mechanisms by which the hydrogels could become tough and stretchable. The team noted the PAAm hydrogels prepared with a crosslinker content of more than 0.1 mole percent to have a much lower toughness than those prepared with a crosslinker content of less than 0.1 mole percent. They determined the experimental crosslinking density of hydrogels from their elastic modulus, the results showed how the entanglement of polymer chains contributed to the high toughness of the PAAm hydrogel with a monomer concentration of 5.0 mol per liter and a crosslinker content of 0.005 mole percent.

The versatile experimental strategy

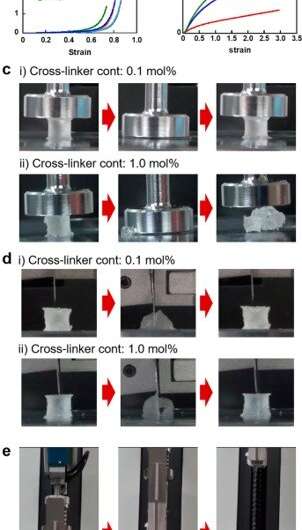

Norioka et al. used the viscous characteristics of the material to relax the applied stress via energy dissipation. The decreased crosslinker content enhanced the contribution of viscosity to the mechanical properties of the hydrogels. The team tuned the conditions for network preparation in the presence of many entanglements, to develop tough and stretchable hydrogels. They then performed further work on dynamic mechanical analysis and homogeneity to examine the mechanism in detail. To demonstrate the versatility of the strategy, Norioka et al. used 2-(Methacryloyloxy)ethyl phosphorylcholine (MPC), a biocompatible zwitterionic polymer used in biomedicine to prepare hydrogels. Although the material has many potential applications in the formation of contact lenses, artificial joints and other biomaterials, they are disadvantaged due to low mechanical strength. The scientists copolymerized the MPC and acrylamides, to prepare poly(2-methacryloyloxyethyl phosphorylcholine) (PMPC), based on a range of monomer concentrations and crosslinker contents. The PMPC hydrogels with a crosslinker content of less than 0.1 mole percent did not break at up to 95 percent strain and 6-MPa stress; the team could not cut the materials with a knife. In addition to that, the PMPC hydrogels with many entanglements exhibited the highest fracture strain due to large elongations. Preparations with a high monomer concentration and low crosslinker content was therefore a universal method to prepare tough and stretchable hydrogels. The resulting material construct contained many physical crosslinks based on polymer chain entanglements for energy dissipation. The team could thus easily prepare tough and stretchable hydrogels by optimizing the preparation conditions to form many polymer chain entanglements without using complex methods.

Outlook

In this way, Chisa Norioka and colleagues introduced a method to tune polymerization conditions without introducing a special structure nor with complicated methods. The team optimized the resulting material using a high monomer concentration and low crosslinker content. The strategy is applicable to prepare tough and stretchable hydrogels using a variety of polymers. The work will lead to many practical applications in biomedicine and bioengineering.

Free-standing photocrosslinked protein polymer hydrogels for sustained drug release

More information:

1. Norioka C. et al. A universal method to easily design tough and stretchable hydrogels, NPG Materials, doi.org/10.1038/s41427-021-00302-2

2. Li J. et al. Designing hydrogels for controlled drug delivery, Nature Review Materials, doi.org/10.1038/natrevmats.2016.71

3. Zhang Y. S. and Khademhosseini A. et al. Advances in engineering hydrogels, Science, 10.1126/science.aaf3627

2021 Science X Network

Citation:

A universal method to easily design tough and stretchable hydrogels (2021, May 13)

retrieved 13 May 2021

from https://phys.org/news/2021-05-universal-method-easily-tough-stretchable.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.