In recent years, engineers at ETH Zurich have developed the technology to produce liquid fuels from sunlight and air. In 2019, they demonstrated the entire thermochemical process chain under real conditions for the first time, in the middle of Zurich, on the roof of ETH Machine Laboratory. These synthetic solar fuels are carbon neutral because they release only as much CO2 during their combustion as was drawn from the air for their production. Two ETH spin-offs, Climeworks and Synhelion, are further developing and commercializing the technologies.

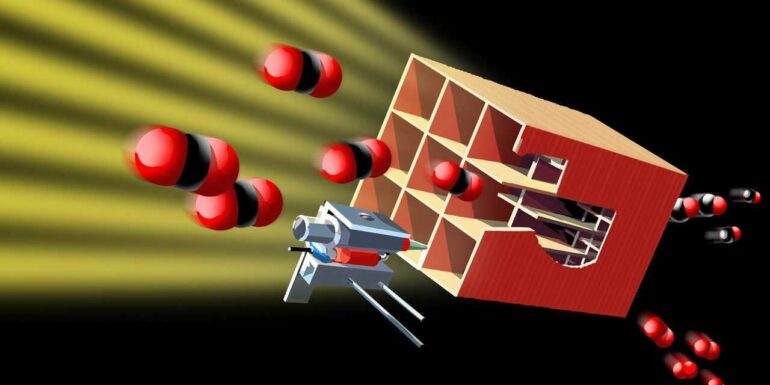

At the heart of the production process is a solar reactor that is exposed to concentrated sunlight delivered by a parabolic mirror and reaches temperatures of up to 1,500°C. Inside this reactor, which contains a porous ceramic structure made of cerium oxide, a thermochemical cycle takes place for splitting water and CO2 captured previously from the air. The product is syngas: a mixture of hydrogen and carbon monoxide, which can be further processed into liquid hydrocarbon fuels such as kerosene (jet fuel) for powering aviation.

Until now, structures with isotropic porosity have been applied, but these have the drawback that they exponentially attenuate the incident solar radiation as it travels into the reactor. This results in lower inner temperatures, limiting the fuel yield of the solar reactor.

Now, researchers from the group of André Studart, ETH Professor of Complex Materials, and the group of Aldo Steinfeld, ETH Professor of Renewable Energy Carriers, have developed a novel 3D printing methodology that enables them to manufacture porous ceramic structures with complex pore geometries to transport solar radiation more efficiently into the reactor’s interior. The research is published in the journal Advanced Materials Interfaces.

Hierarchically ordered designs with channels and pores that are open at the surface exposed to the sunlight and become narrower towards the rear of the reactor have proven to be particularly efficient. This arrangement enables to absorb the incident concentrated solar radiation over the entire volume. This in turn ensures that the whole porous structure reaches the reaction temperature of 1,500°C, boosting the fuel generation.

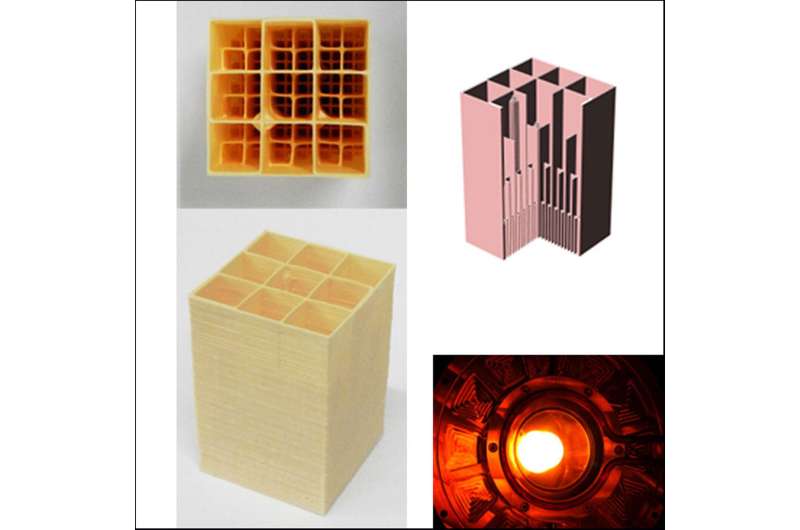

These ceramic structures were manufactured using an extrusion-based 3D printing process and a new type of ink with optimal characteristics developed specifically for this purpose, namely: low viscosity and a high concentration of ceria particles to maximize the amount of redox active material.

3D digital representation (upper right) and photographs (side and top view) of the porous ceramic structure with hierarchically channelled topology. The solar reactor (bottom right) contains an array of these graded structures, which are directly exposed to concentrated solar radiation. © Advanced Materials Interfaces (2023). DOI: 10.1002/admi.202300452

Successful initial testing

The researchers investigated the complex interplay between the transfer of radiant heat and the thermochemical reaction. They were able to show that their new hierarchical structures can produce twice as much fuel as the uniform structures when subjected to the same concentrated solar radiation of intensity equivalent to 1,000 suns.

The technology for 3D printing the ceramic structures is already patented, and Synhelion has acquired the license from ETH Zurich. “This technology has the potential to boost the solar reactor’s energy efficiency and thus to significantly improve the economic viability of sustainable aviation fuels,” Steinfeld says.

More information:

Sebastian Sas Brunser et al, Solar‐Driven Redox Splitting of CO2 Using 3D‐Printed Hierarchically Channeled Ceria Structures, Advanced Materials Interfaces (2023). DOI: 10.1002/admi.202300452

Citation:

3D-printed reactor core makes solar fuel production more efficient (2023, October 27)