From televisions to X-ray machines, many modern technologies are enabled by electrons that have been juiced up by a particle accelerator. Now, the U.S. Department of Energy’s Thomas Jefferson National Accelerator Facility has worked with General Atomics and other partners to unlock even more applications by exploring the process of designing, prototyping and testing particle accelerators that are more powerful and efficient, while also less expensive and bulky.

The research included the design and fabrication of crucial elements of a prototype particle accelerator, featuring advanced commercial off-the-shelf cooling components and novel superconducting materials. The prototype was successfully tested, demonstrating the feasibility of the design for commercial applications. The work was recently published in Physical Review Accelerators and Beams.

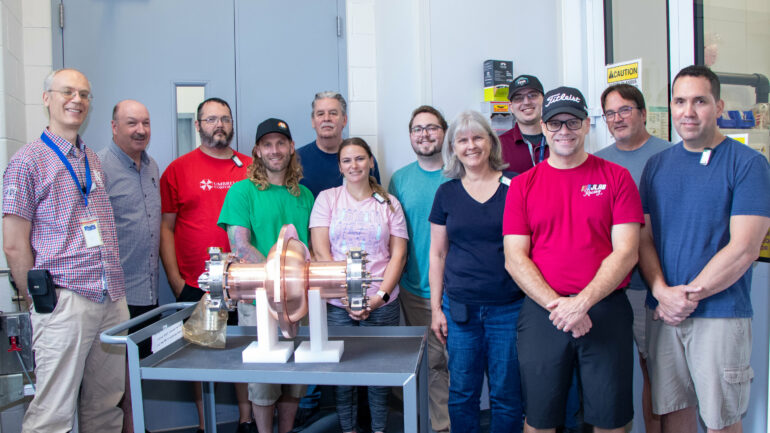

Members of the team at Jefferson Lab have extensive experience in building advanced particle accelerators for basic research. For this project, Jefferson Lab subcontracted with General Atomics to begin moving beyond the technology’s applications in basic research to look toward possible societal benefits.

The researchers began the work by focusing on superconducting radiofrequency (SRF) accelerator components called resonant cavities at Jefferson Lab. Particle accelerators built on SRF cavities enable some of the most powerful research machines in the world, including Jefferson Lab’s own Continuous Electron Beam Accelerator Facility. CEBAF is a DOE Office of Science user facility that is dedicated to revealing the underlying structures of protons and neutrons in the atom’s nucleus.

Particle accelerators juice up electrons by giving them extra energy measured in electron-Volts (eV), thus “accelerating” the electrons. Electrons, accelerated in a similar fashion as in CEBAF but at a much smaller scale, can be used to render images on a television screen, make X-rays to image patients, or clean up wastewater and flue gases.

The need for cold systems

While SRF cavities are very efficient at accelerating particle beams, these systems can be very expensive to build and run. One of the biggest expenses is their cooling requirements. In a typical research machine, for instance, SRF cavities must be extremely cold—at 2 Kelvin or -456° F, which is just a few degrees above absolute zero—to achieve the most efficient superconductive operation.

“The typical means of cooling an SRF cavity is with a large system called a liquid helium cryogenics plant. These systems are expensive to install and operate,” said Drew Packard, a scientist with the Magnetic Fusion Energy (MFE) division of General Atomics, who is collaborating on the project.

Helium is commonly recognized as the gas used to make floating balloons, because it is lighter than air. Liquefied helium, held below 4.2 Kelvin, is the element of choice to cool superconducting cavities to their very low temperatures. The helium flows over the exterior surface of the cavities in a process called convection, removing heat and keeping the temperature low. This process is similar to how an air conditioner works.

The cryoplants required to keep helium at this low temperature are complicated to design and operate, as noted by Packard. Helium is also a relatively rare, nonrenewable resource with a complex manufacturing process.

The General Atomics team designed and tested a horizontal cryostat that instead cools the cavities using conduction cooling. The system makes use of readymade cryogenic systems called “cryocoolers.” These devices are already widely used to cool superconducting magnets in magnetic resonance imaging (MRI) machines in hospitals.

Very low temperatures can be achieved while removing substantial amounts of heat by mounting the highly conductive “cold head” of the cryocooler directly to the cavity. The cooling power of commercial cryocoolers has been steadily increasing over the past years, with up to 5 W at 4.2 Kelvin currently available.

“One of the breakthrough technologies is the ability to cool the cavity by conduction with these compact commercial devices, instead of having large, complex and more expensive cryogenic cooling plants,” said Gianluigi “Gigi” Ciovati, a Jefferson Lab staff scientist who is leading the project. “Liquid helium cryoplants won’t be needed for the system we are working on.”

While liquid helium will continue to play an important role for large accelerators conducting basic and applied research, helium-free conductive cooling techniques will pave the way for more compact technologies that can serve other purposes.

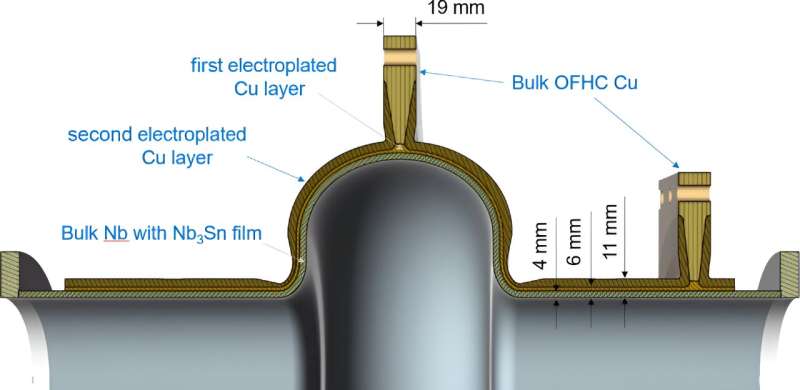

Cross-section layout of the 952.6 MHz prototype cavity for conduction-cooling demonstration. © Physical Review Accelerators and Beams (2023). DOI: 10.1103/PhysRevAccelBeams.26.044701

Prototyping the cavity

The system designed by the team incorporated several state-of-the-art advances, as well as a few new ones. First, the particle accelerator cavity design worked on at Jefferson Lab had some special features.

Like most SRF particle accelerator cavities, it was made of a material called niobium. Niobium becomes superconducting at temperatures near absolute zero. However, this prototype cavity had one layer of a special niobium-tin material (Nb3Sn) added to its inside surface. Niobium-tin becomes superconducting at a higher temperature than that of pure niobium. Using this material meant that the accelerator cavity could function efficiently at more than twice the low temperatures needed for ordinary niobium—beyond 4 Kelvin.

The outside of the prototype particle accelerator cavity design also received special attention. It first received a thin layer (2 mm) of copper cladding. It was then studded with three copper tabs, where the cryocooler systems could be attached to the cavity. Finally, it received a thick layer of copper cladding (5 mm). Much like that in a cooking pot, the cladding helps the cavity easily transfer heat.

“We basically built a copper thermal blanket on the outside of the cavity by a combination of cold spray and electroplating. This provides a high thermal conductivity path for the heat generated on the inner surface to move to the outer surface and then towards the cryocooler,” Ciovati explained.

A prototype cavity was first tested at Jefferson Lab in a liquid helium bath at 4.3 Kelvin (-452° F). This is similar to the performance testing that an accelerating cavity would receive before being installed in a research machine. The tests establish a baseline for expected performance.

Putting it all together

A similarly outfitted prototype cavity was then shipped to General Atomics for its tests in a prototype horizontal cryostat, similar to a cryomodule used in SRF-based particle accelerators.

“First, the cryostat was evacuated of air, and then the cavity was cooled below its superconducting threshold and excited with a small RF signal to demonstrate the electrical accelerating gradient,” Packard said. “With the diagnostics, we demonstrated that the conduction-cooled cavity performance achieved the same specifications as the previous liquid helium tests performed at Jefferson Lab.”

While cooled to about 4 Kelvin by just three attached commercial cryocoolers, the component achieved a peak surface magnetic field of 50 milliTesla, the highest ever achieved in this type of setup, while also delivering stable operation.

The result meets the requirements for an accelerator capable of producing electrons with a 1 MeV energy gain (1 million electron-Volts), which could find use in environmental remediation applications. Electron beams near this energy are useful for other industrial processes, such as material processing or imaging.

“Electron beams are useful in a variety of commercial applications. This compact superconducting accelerator technology has considerable potential for environmental remediation, one example being water purification,” Packard said. “Untreated water may contain unsafe concentrations of chemicals such as pharmaceuticals or PFAS, as well as harmful pathogens such as E. coli or salmonella. Electron beams are very effective at tearing apart and breaking down complex molecules and organics into more basic particles that are less threatening to human health and the environment.”

“The accelerators that we’re envisioning are capable of delivering between one and 10 MeV,” said Ciovati. “This prototype is still a bit smaller than that, but it demonstrates that this breakthrough design, with the ability to cool the cavities with these commercial devices, is feasible.”

By successfully designing, building and operating the prototype particle accelerator with a combination of industry-made parts and off-the-shelf commercial conduction cryocoolers, the two teams have taken a big step toward making efficient, compact and reliable SRF accelerators a reality for commercial applications.

“There was a fair amount of involvement with the industrial partners—from the cavity fabrication and the production to the final testing. I was very impressed and pleased with the amount of technical expertise, knowledge and commitment that I found in all the industrial partners I’ve worked with,” Ciovati said.

Moving forward

The next step is to focus on a combination of design improvements and further testing.

“We’re going to evaluate higher-energy cavities that enable deeper penetration of the electron beam into materials,” Packard said. “We are also focused on building up the complete system by integrating the cryomodule with additional subsystems, as well as investigating ways to make the system cheaper.”

More information:

G. Ciovati et al, Development of a prototype superconducting radio-frequency cavity for conduction-cooled accelerators, Physical Review Accelerators and Beams (2023). DOI: 10.1103/PhysRevAccelBeams.26.044701

Provided by

Thomas Jefferson National Accelerator Facility

Citation:

Conduction-cooled accelerating cavity proves feasible for commercial applications (2024, February 29)