Some say there are two types of concrete – cracked and on the brink of cracking. But what if when concrete cracked, it could heal itself?

We’re part of a team of materials scientists and microbiologists that has harnessed the power of bacteria to create biological fibers that initial results suggest can heal cracks in concrete. We’re working on a technology that, if we work out the kinks and manage to bring it to the market one day, could extend the life span of concrete.

Cracking concrete

Picture a bridge exposed to snow, rain, temperature changes and trucks carrying heavy loads. The concrete on the bridge will gradually develop cracks from stress and wear. Over time, these cracks expand, allowing water and corrosive substances that weaken the concrete to penetrate further down.

At some point, local authorities have to pay for repairs, which are not only expensive but also disrupt traffic and drain public resources.

Now, consider a medical patient recovering from a severe injury. As the patient’s cells recognize the damage, they release tiny healing agents – like microscopic repair crews. These agents target the wounded area, mending tissues and restoring the cells’ functionality. What if concrete had the same kind of self-healing ability as human tissue?

A self-healing concrete

Our team at the Advanced Infrastructure Materials lab at Drexel University was inspired by self-healing tissue in the human body. We developed an addition to concrete we call BioFiber.

BioFiber has three essential functions: It heals itself on its own, it stops cracks from growing wider, and it remains intact inside the concrete when there aren’t any cracks.

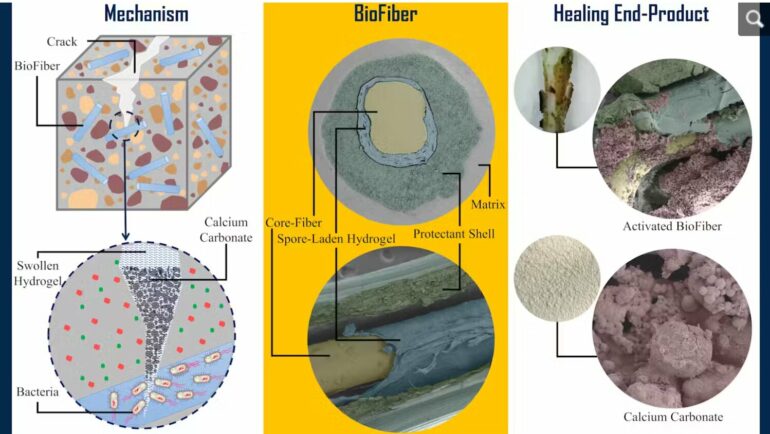

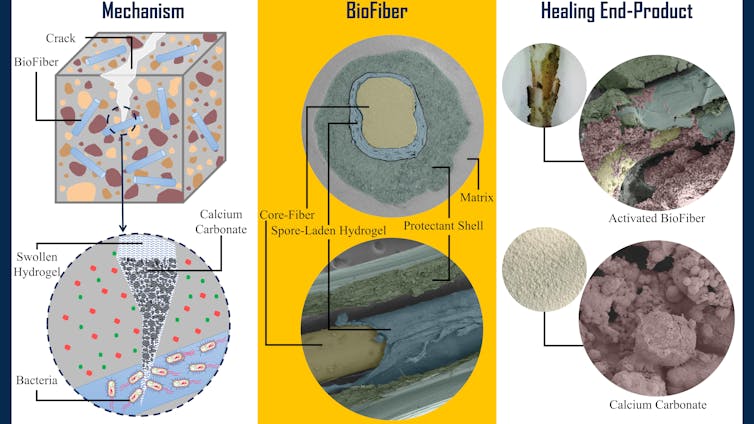

BioFiber’s mechanism and structure.

Mohammad Houshmand via Elsevier

Each BioFiber has three key components: a tough core fiber made of a polymer called polyvinyl alcohol, a porous layer of hydrogel infused with Lysinibacillus sphaericus bacteria, and a damage-responsive outer shell. When cracks hit the BioFiber, its outer shell breaks and releases the bacteria into the crack, which starts the self-healing process.

The strong core fibers in BioFiber bridge the cracks and stop them from growing wider during the healing process.

Surrounding the core fiber, the hydrogel layer is made up of a mesh of polymer chains at the molecular level that attract water. Their spongelike structure can absorb and hold large volumes of water. During the production process, we add calcium to help the hydrogel solidify.

The hydrogel itself is made up of a natural polymer found in seaweed called alginate, which has special properties that allow it to trap bacteria. Alginate isn’t toxic and is even safe for biomedical applications such as drug delivery and tissue engineering.

The hydrogel houses endospores, which are dormant bacteria. Once the outer shell cracks and the endospores are awakened from their dormant state, they facilitate the self-healing….