Washington State University scientists successfully tested a new way to produce sustainable jet fuel from lignin-based agricultural waste. Published in the journal Fuel Processing Technology, the team’s research demonstrated a continuous process that directly converts lignin polymers, one of the chief components of plant cells, into a form of jet fuel that could help improve performance of sustainably produced aviation fuels.

“Our achievement takes this technology one step closer to real-world use by providing data that lets us better gauge its feasibility for commercial aviation,” said lead scientist Bin Yang, professor in WSU’s Department of Biological Systems Engineering.

A class of structural molecules that make plants tough and woody, lignin is derived from corn stover—the stalks, cobs and leaves left after harvest—and other agricultural byproducts.

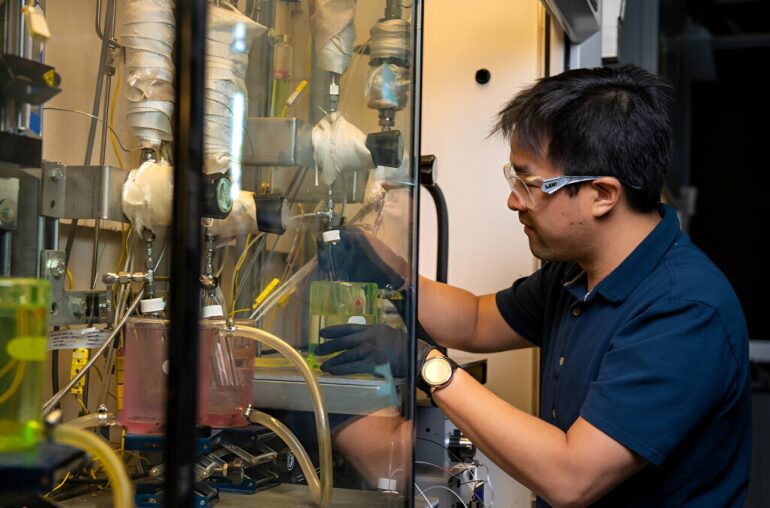

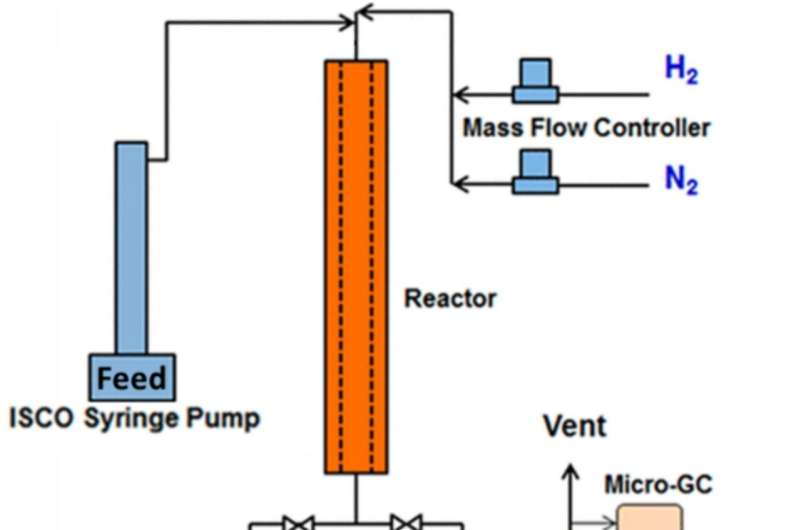

The team developed a process called “simultaneous depolymerization and hydrodeoxygenation,” which breaks down the lignin polymer and at the same time removes oxygen to create lignin-based jet fuel. At their Richland facility, the scientists introduced dissolved lignin polymer into a continuous hydrotreating reactor to produce the fuel.

Global consumption of aviation fuel reached an all-time high of nearly 100 billion gallons in 2019, and demand is expected to increase in the coming decades. Sustainable aviation fuels derived from plant-based biomass could help minimize aviation’s carbon footprint, reduce contrails and meet international carbon neutrality goals.

Lignin-based jet fuel could make sustainable fuels cleaner and more easily usable in jet engines. Thanks to their density, efficiency, and seal-swelling characteristics, hydrocarbons catalyzed from lignin could effectively replace fossil fuel-derived compounds called aromatics. Associated with contrails and climate impacts, aromatics remain in use because they enhance fuel density and help swell O-rings in metal-to-metal joints.

Trickle bed reactor used for direct and continuous SDHDO of lignin. © Fuel Processing Technology (2024). DOI: 10.1016/j.fuproc.2024.108129

This research marked the team’s first successful test of a continuous process, which is more feasible for commercial production. The project also used a less processed, less expensive form of lignin derived from corn stover, dubbed “technical lignin,” contrasting similar research using extracted lignin bio-oil.

The team’s findings suggest lignin is a promising source of aromatic-replacing cycloalkanes and other useful fuel compounds.

“The aviation enterprise is looking to generate 100% renewable aviation fuel,” said Josh Heyne, research team member and co-director of the WSU-PNNL Bioproducts Institute. “Lignin-based jet fuel complements existing technologies by, for example, increasing the density of fuel blends.”

Offering reduced emissions, lignin-based fuel could ultimately make sustainable aviation fuels fully “drop-in” capable, meaning they can be used with all existing engines, infrastructure and aircraft like existing fossil-derived aviation fuel.

“We’re working to create an effective, commercially relevant technology for a complementary blend component that can achieve the 100% drop-in goal,” Heyne said.

The team is now working to refine their process for better efficiency and reduced costs.

More information:

Adarsh Kumar et al, A simultaneous depolymerization and hydrodeoxygenation process to produce lignin-based jet fuel in continuous flow reactor, Fuel Processing Technology (2024). DOI: 10.1016/j.fuproc.2024.108129

Provided by

Washington State University

Citation:

New continuous reaction process can help turn plant waste into sustainable aviation fuel (2024, September 26)