University of Virginia School of Engineering and Applied Science professor Eric Loth, who led a multi-institutional team in designing one of the world’s largest wind turbines, is mentoring the next generation of students who are exploring next-generation wind turbine designs.

Loth’s graduate research assistant, doctoral student Michael Jeong, was the lead author earlier this year on a paper published in Applied Energy that revealed promising new rotor designs that could significantly enhance power and performance of offshore wind turbines. The research takes into account the complex fluid-structure dynamics that become critical at these extreme scales.

As the push for larger and more efficient turbines grows, this research offers critical insights into maximizing energy production while minimizing rotor weight and the associated costs.

The UVA researchers partnered with the National Renewable Energy Laboratory, and engineering professors at Washington State University and the University of Illinois at Urbana-Champaign.

“Our research focuses on designing cost-efficient wind turbine rotors at unprecedented sizes, meant to operate offshore where winds are stronger,” Jeong said.

“Models like 25 MW Segmented Ultralight Morphing Rotor (SUMR) envisioned by Professor Loth are among the largest designs to be published and promise high energy capture while optimizing costs. With wind turbines continuously growing in size, it has become essential to improve on design strategies and to consider the structural challenges for turbines at these scale.”

The design study

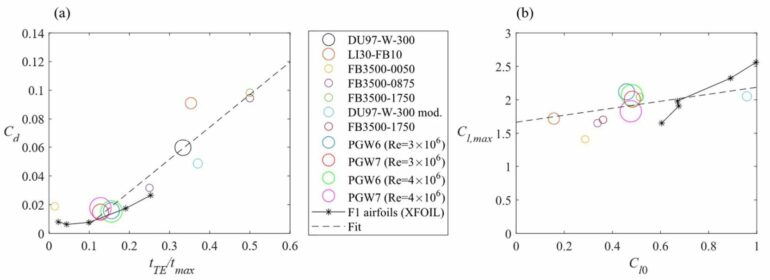

The team used a multi-disciplinary computational approach to generate the size and shape of wind turbine blades for three different innovative rotors, all aimed at aerodynamically maximizing power generation.

“We designed rotors with small, medium and large blade widths relative to the blade length and used wind turbine simulation codes to predict which of the three rotors performs the best in the highly sheared wind typical of offshore conditions,” Jeong said.

By adjusting rotor “coning,” which represents and angle outside of the standard plane of rotation, rotor tilt from the vertical plane, and the geometry of the blade design, highly efficient energy capture was achieved by maximizing the area of the rotor, while minimizing its cost.

The researchers also focused on the rotor’s “lift coefficient distribution,” a term that describes how well the cross-sectional shape of the blades catch the wind along its span. By optimizing these coefficients, along with blade angles, the team created a specialized framework for designing extremely large blades that are aerodynamically and structurally viable.

Their simulations indicated that one of the designs—featuring a moderately balanced blade width—performed best overall, generating the highest power while maintaining lower weight and cost.

“The impact of Michael’s work extends beyond just one turbine design,” Loth added. “It lays the foundation for future innovations in wind energy technology.”

Loth is the Rolls-Royce Commonwealth Professor and director of the UVA Fluids Research and Innovation Lab. He is an expert in wind energy who has addressed the U.S. Congress about his collaborative SUMR project.

He has also given invited talks at Cambridge University, the University of Pennsylvania, Princeton University, Oxford University, Harvard University and the Massachusetts Institute of Technology.

Jeong, who graduates in December, said he has been fortunate to have had Loth as his graduate mentor.

More information:

Michael Jeong et al, Aerodynamic rotor design for a 25 MW offshore downwind turbine, Applied Energy (2023). DOI: 10.1016/j.apenergy.2023.122035

Provided by

University of Virginia

Citation:

Engineers design innovative 25 MW rotors to keep pace with wind turbine growth (2024, November 6)