Batteries have become an integral component of modern technology. Lithium-ion batteries (LIBs) can be found virtually everywhere, from handheld electronic devices and electric vehicles to the large power banks used in renewable energy generation systems. However, current LIB designs suffer from some crippling drawbacks, including low durability and the use of toxic liquid electrolytes.

To address these limitations, scientists have been studying all-solid-state batteries for over a decade. Although silicon-based all-solid-state batteries should be theoretically more durable than conventional LIBs, an unsolved challenge still stands before this becomes a reality.

When a Si-based all-solid-state battery undergoes charge/discharge cycles, the negative Si electrode repeatedly expands and contracts. This puts a lot of mechanical stress on the interface between the electrode and the stiff solid electrolyte, causing the former to ultimately crack, detach, and suffer an irreversible dip in performance.

Against this backdrop, a research team led by Professor Takayuki Doi from Doshisha University, Japan, explored a promising solution for all-solid-state batteries.

As explained in their paper, which was made available online and published in ACS Applied Materials & Interfaces on October 29, 2024, the researchers investigated whether adding pores to a silicon oxide (SiOx) electrode could prevent the cracking and peeling problems caused by the expansion and contraction seen in Si electrodes.

The study was co-authored by Dr. Kohei Marumoto from Doshisha University, Japan, and Dr. Kiyotaka Nakano from Hitachi High-Tech Corporation, Japan.

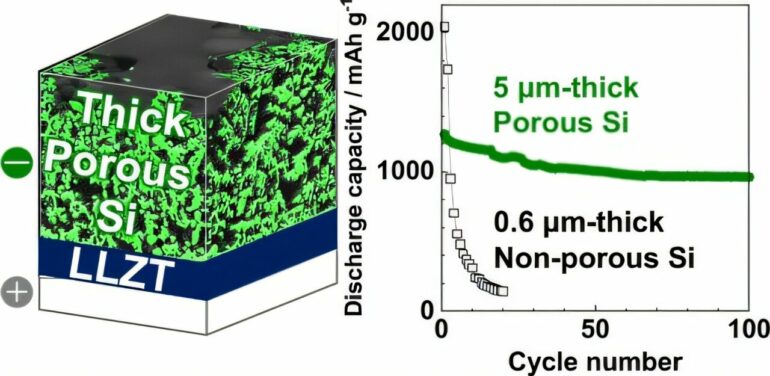

To test their hypothesis, the researchers synthesized porous SiOx electrodes via radiofrequency sputtering and used them to fabricate various all-solid-state cells, using Li-La-Zr-Ta-O (LLZTO) as a solid electrolyte. They analyzed the obtained pore structures in detail using advanced scanning electron microscopy techniques and investigated their correlation with the overall performance of the cells after repeated charge/discharge cycles.

Interestingly, the highly porous SiOx electrodes offered much better cycling performance compared to non-porous SiOx, which suffered from a massive capacity drop after cycling. Microscopy observations clearly explained what was going on at the nanometer scale.

“Non-porous SiOx partially exfoliated from the LLZTO electrolyte by the 20th cycle, which was consistent with the drastic decline in capacity and rise in internal resistance we observed,” says Dr. Doi.

“In contrast, though the initially observed pore structure of porous SiOx collapsed through repeated expansion and contraction, the remaining pores still served as a buffer against the internal and interfacial stresses. This ultimately helped maintain the interfacial joint between the electrode and the electrolyte.”

One pressing limitation of both Si and SiOx electrodes in all-solid-state batteries is that their thickness must be kept extremely low (less than a micrometer) to prevent cracking and exfoliation. However, after adding pores to SiOx, stable charge-discharge cycles could be obtained even in SiOx films as thick as 5 µm.

This translates to a massive boost in terms of space efficiency, as more energy can be stored per unit volume. “The thicker SiOx films we achieved resulted in an energy density of the negative electrode approximately 17 times higher than that of conventional non-porous silicon electrodes,” highlights Dr. Doi.

Taken together, the findings of this study shed light on how porous structures can be leveraged to unlock the true potential of all-solid-state batteries. Such energy-storing devices will play a crucial role in charting our path towards sustainable societies, given their promising applications in domestic and industrial-scale energy generation.

Moreover, thanks to their enhanced safety profile and longer lives, all-solid-state batteries could make electric vehicles a much more attractive option for consumers.

“We expect the results of our research to make a multifaceted contribution towards sustainable development goals, not only in terms of climate change countermeasures based on the reduction of carbon emissions, but also in terms of economic growth and urban development,” adds Dr. Doi, while sharing his concluding thoughts.

Further studies will be needed to fully optimize the porous structure of solid SiOx electrolytes to achieve maximum performance in all-solid-state batteries. With much luck, future developments in this exciting field will lead to a much-needed breakthrough in energy storage.

More information:

Kohei Marumoto et al, Tailored Design of a Nanoporous Structure Suitable for Thick Si Electrodes on a Stiff Oxide-Based Solid Electrolyte, ACS Applied Materials & Interfaces (2024). DOI: 10.1021/acsami.4c15894

Provided by

Doshisha University

Citation:

Porous electrode design could boost all-solid-state battery performance and lifespan (2024, December 16)