University of Queensland researchers have developed a 3D printing method to produce shape-shifting liquid metal robotics with musculoskeletal qualities inspired by animal physiology.

Dr. Ruirui Qiao and her research team at the Australian Institute for Bioengineering and Nanotechnology (AIBN) have used the technique to make medical rehabilitation components and devices with superior strength and flexibility. The research is published Advanced Materials.

“We set out to mimic the locomotion, flexibility and control of mammalian movement,” Dr. Qiao said.

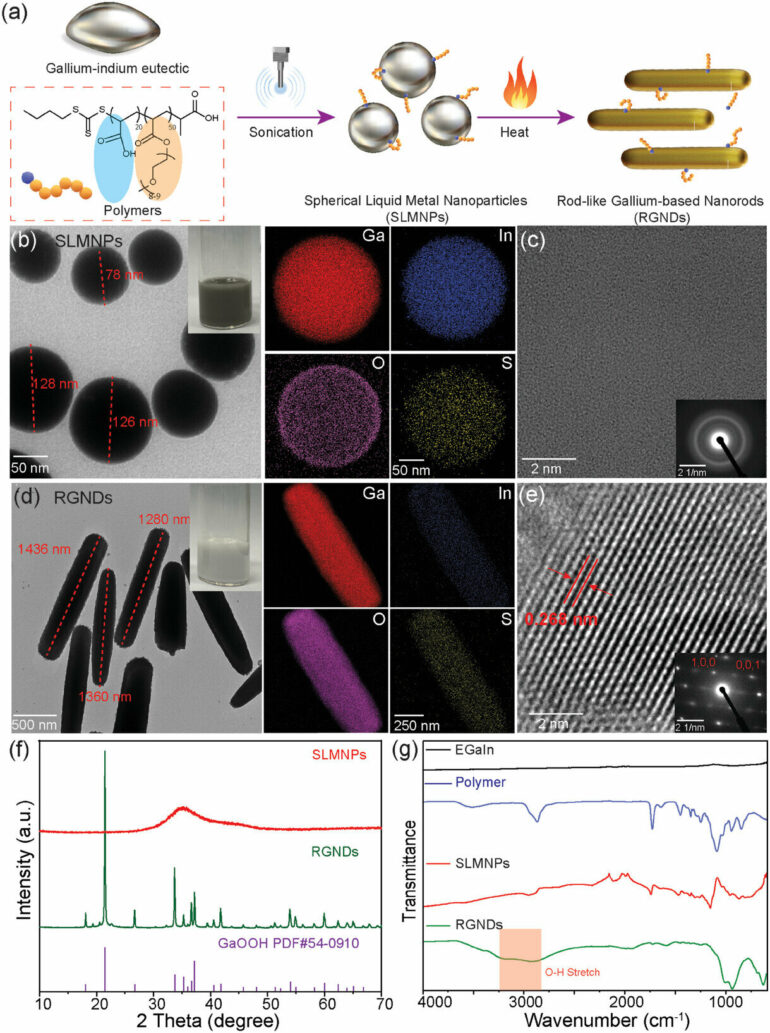

“By combining ‘soft’ spherical liquid metal nanoparticles and ‘rigid’ rod-like gallium-based nanorods in the 3D printing process, we have been able to replicate the interconnected network of bone and muscle that gives animals an advantage in efficiency and strength.

“This tuneable gallium-polymer composite can be used for next generation medical rehabilitation products like high-precision grippers for prosthetic limbs.”

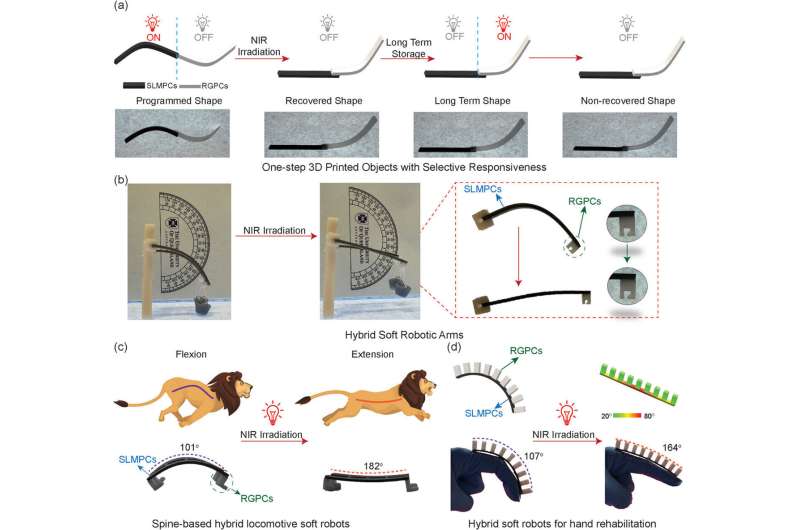

Similarly to Dr. Qiao’s previous work with liquid metal, the new creations are capable of taking and holding different shapes and functions when exposed to stimuli such as heat and infrared light.

Dr. Qiao said many manufacturers draw inspiration from the locomotion mechanisms of soft-bodied creatures in nature.

Applications of one-step 3D-printed hybrid soft robots. (a) Selective shape changes of 3D-printed hybrid composites containing SLMNPs and RGNDs under NIR light irradiation (λmax = 808 nm, 0.3 W cm−2. © Advanced Materials (2024). DOI: 10.1002/adma.202409789

“But making hybrid structures is very challenging due to limitations in material selection as well as the complex, multi-step processes involved in traditional manufacturing methods,” she said.

“We developed a new method to mimic animal physiology to benefit our own technology using a quick and simple manufacturing process.”

Dr. Qiao said given the ease of fabrication and its potential applications, the soft-rigid polymer composite could revolutionize the field of hybrid soft materials and accelerate innovations in soft robotics.

“We would like to see research that advances 3D printing technologies and design strategies, focusing on increasing the proportion of metal-based nanoparticles within the 3D-printed composite,” she said.

“This will further enhance responsive properties and ultimately improve the performance of hybrid soft robots.”

The project involved AIBN researchers including Xumin Huang, Jiangyu Hang, Naufal Kabir Ahamed Nasar, Thomas Quinn, Dr. Liwen Zhang, and Professor Tom Davis.

More information:

Xumin Huang et al, 4D Printing Hybrid Soft Robots Enabled by Shape‐Transformable Liquid Metal Nanoparticles, Advanced Materials (2024). DOI: 10.1002/adma.202409789

Provided by

Australian Institute for Bioengineering and Nanotechnology (AIBN)

Citation:

Giving animal strength to medical robotics: 3D printing method uses shape-shifting liquid metal (2024, December 18)