Today, approximately 1,800,000 acres of land in the United States is used for landfill waste disposal. In terms of volume, the U.S alone generated over 290 million tons of solid waste in 2018, an amount equivalent to about 235,000 Olympic-size swimming pools, assuming an average solid waste density of a half ton per cubic meter.

Roughly 9% – about 26 million tons – of this waste is made up of iron and steel. These are resources with a stable market value used in various civil infrastructure projects. As a team of environmental engineers, we wanted to know whether we could use iron-rich waste to produce iron oxide nanoparticles – a useful tool for combating water pollution and building engineering hardware.

All about nanoparticles

Iron oxide nanoparticles consist of iron and oxygen atoms and, because of their size, they exhibit unique physical and chemical properties. They are extremely small, typically at the nanoscale – one-billionth of a meter – in diameter.

The iron oxide nanoparticles we synthesized were a distinctive group called magnetite and maghemite. Initial studies have shown that nanoparticles in this group could help drugs get to the right part of the body, make batteries in electric vehicles more efficient and improve sensors for detecting toxic gas, as well as sound and motion.

Because these nanoparticles are made of iron, they’re both magnetic and stable. Their tiny size gives them a large surface area relative to their volume, allowing them to grab pollutants in water. Additionally, their magnetic nature makes them ideal for building extremely small and thin electrical components.

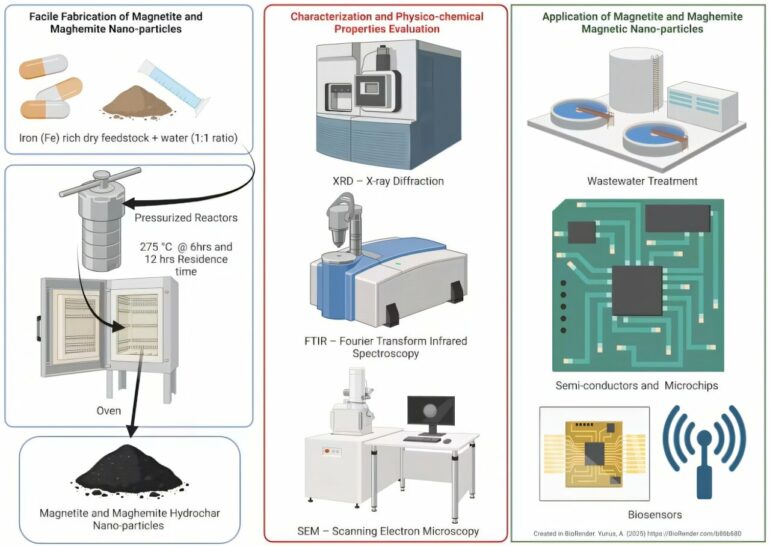

In our work, we wanted to find a new way to produce them using waste materials. In our newest study, published in the RSC Sustainability journal, we developed an eco-friendly method to synthesize iron oxide nanoparticles from expired over-the-counter iron supplements. This approach not only gives value to discarded products but also supports a more sustainable and circular method of production.

The research process

To conduct our study, we used a method called hydrothermal carbonization to produce these magnetic nanoparticles. We were able to source a large amount of expired iron supplements from a local health care center.

The hydrothermal carbonization process uses a turbocharged version of the kind of pressure cooker you might have in your kitchen. For our recipe, we combined 20 grams each of expired iron supplements and water in a specialized pressure reactor. We then cooked the mixture at 527 degrees Fahrenheit (275 degrees Celsius) for six to 12 hours. Under this intense temperature and pressure, the supplements broke down, which produced tiny – 10- to 11-nanometer – particles.

The end product included a solid charcoal-like material called hydrochar, which made up about 20% to 22% of the product. The hydrochar consisted of the iron oxide nanoparticles and graphite, a carbon-rich material that gave the…