Photocurable 3D printing, widely used for everything from dental treatments to complex prototype manufacturing, is fast and precise but has the limitation of being fragile and easily broken by impact. A KAIST research team has developed a new technology to overcome this weakness, paving the way for the more robust and economical production of everything from medical implants to precision machine parts.

Professor Miso Kim’s research team in the Department of Mechanical Engineering has developed a digital light processing (DLP)-based 3D printing technology that fundamentally resolves the durability limitations of photocurable 3D printing. The paper is published in the journal Advanced Materials.

The technique uses light to solidify liquid resin (polymer) to rapidly manufacture precise structures, which are used in various fields, including dentistry and precision machinery. While traditional injection molding offers excellent durability, it requires significant time and cost for mold fabrication. In contrast, photocurable 3D printing allows for flexible shape realization but has a durability drawback.

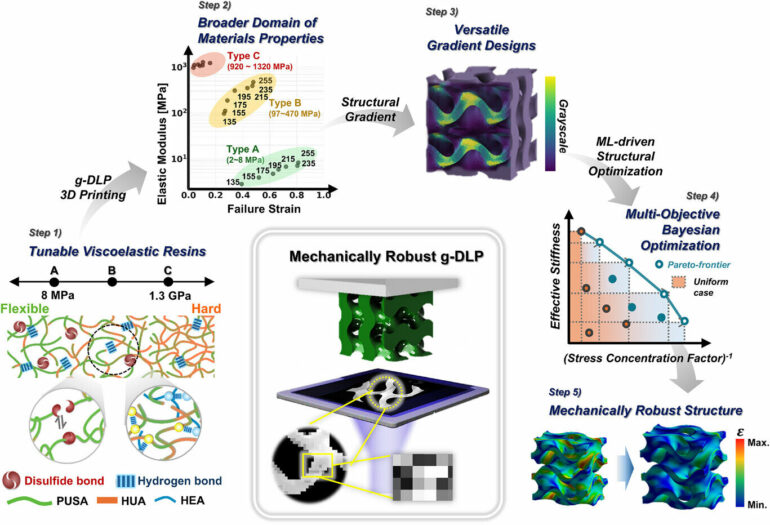

Professor Kim’s team solved this problem by combining two key elements:

A new photocurable resin material that absorbs shock and vibration while allowing for a wide range of properties from rubber to plastic. A machine learning-based design technology that automatically assigns optimal strength to each part of the structure.

The research team developed a polyurethane acrylate (PUA) material incorporating dynamic bonds, which significantly increases shock and vibration absorption capability compared to existing materials.

In addition, they successfully applied “grayscale DLP” technology, which controls the light intensity to achieve different strengths from a single resin composition, thereby assigning customized strength to specific areas within the structure. This concept is inspired by the harmonious and different roles played by bone and cartilage in the human body.

A machine learning algorithm automatically proposes the optimal strength distribution by analyzing the structure and load conditions. This organically connects material development and structural design, enabling customized strength distribution.

The economic efficiency is also noteworthy. Previously, expensive “multi-material printing” technology was required to achieve diverse material properties, but this new technology yields the same effect with a single material and a single process, significantly reducing production costs. It eliminates the need for complex equipment or material management, and the AI-based structural optimization shortens research and development time and product design costs.

Professor Kim explained, “This technology simultaneously expands the degrees of freedom in material properties and structural design. Patient-specific implants will become more durable and comfortable, and precision machine parts can be manufactured more robustly.

“The fact that it secures economic viability by realizing various strengths with a single material and single process is highly significant. We anticipate its utilization across various industrial fields such as biomedical, aerospace, and robotics.”

More information:

Jisoo Nam et al, Machine Learning-Driven Grayscale Digital Light Processing for Mechanically Robust 3D-Printed Gradient Materials, Advanced Materials (2025). DOI: 10.1002/adma.202504075

Provided by

The Korea Advanced Institute of Science and Technology (KAIST)

Citation:

3D printing becomes stronger and more economical with light and AI (2025, September 30)