Inspired by the human eye, our biomedical engineering lab at Georgia Tech has designed an adaptive lens made of soft, light-responsive, tissuelike materials.

Adjustable camera systems usually require a set of bulky, moving, solid lenses and a pupil in front of a camera chip to adjust focus and intensity. In contrast, human eyes perform these same functions using soft, flexible tissues in a highly compact form.

Our lens, called the photo-responsive hydrogel soft lens, or PHySL, replaces rigid components with soft polymers acting as artificial muscles. The polymers are composed of a hydrogel − a water-based polymer material. This hydrogel muscle changes the shape of a soft lens to alter the lens’s focal length, a mechanism analogous to the ciliary muscles in the human eye.

The hydrogel material contracts in response to light, allowing us to control the lens without touching it by projecting light onto its surface. This property also allows us to finely control the shape of the lens by selectively illuminating different parts of the hydrogel. By eliminating rigid optics and structures, our system is flexible and compliant, making it more durable and safer in contact with the body.

Why it matters

Artificial vision using cameras is commonplace in a variety of technological systems, including robots and medical tools. The optics needed to form a visual system are still typically restricted to rigid materials using electric power. This limitation presents a challenge for emerging fields, including soft robotics and biomedical tools that integrate soft materials into flexible, low-power and autonomous systems. Our soft lens is particularly suitable for this task.

Soft robots are machines made with compliant materials and structures, taking inspiration from animals. This additional flexibility makes them more durable and adaptive. Researchers are using the technology to develop surgical endoscopes, grippers for handling delicate objects and robots for navigating environments that are difficult for rigid robots.

The same principles apply to biomedical tools. Tissuelike materials can soften the interface between body and machine, making biomedical tools safer by making them move with the body. These include skinlike wearable sensors and hydrogel-coated implants.

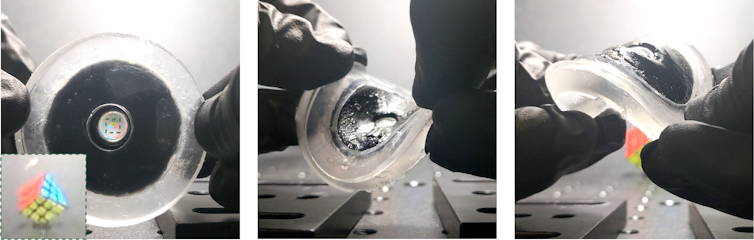

This variable-focus soft lens, shown viewing a Rubik’s Cube, can flex and twist without being damaged.

Corey Zheng/Georgia Institute of Technology

What other research is being done in this field

This work merges concepts from tunable optics and soft “smart” materials. While these materials are often used to create soft actuators – parts of machines that move – such as grippers or propulsors, their application in optical systems has faced challenges.

Many existing soft lens designs depend on liquid-filled pouches or actuators requiring electronics. These factors can increase complexity or limit their use in delicate or…