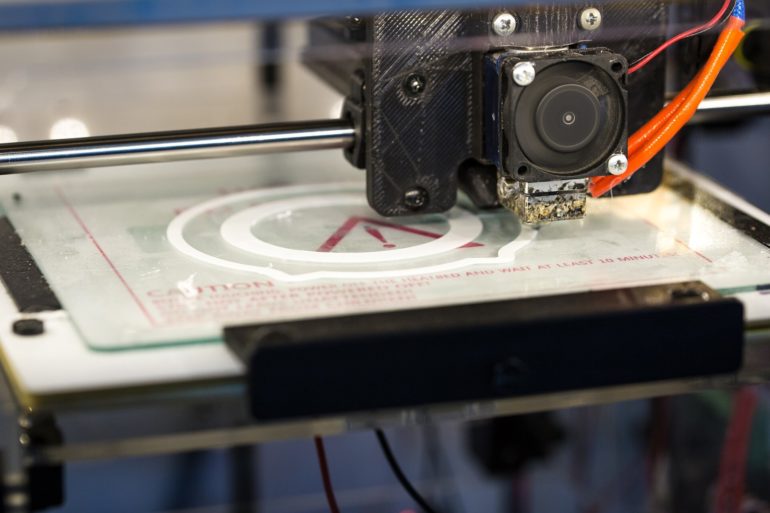

Three-dimensional (3-D) printing techniques have the ability to fabricate wearable sensors with customized and complex designs compared with conventional processes. The vat photopolymerization 3-D printing technique exhibits better printing resolution, faster printing speed, and is capable of fabricating a refined structure. Due to the lack of highly conductive photocurable resins, it is difficult to prepare sensors through vat photopolymerization 3-D printing technique.

In a study published in Advanced Functional Materials, the research group led by Prof. Wu Lixin from Fujian Institute of Research on the Structure of Matter (FJIRSM) of the Chinese Academy of Sciences developed porous flexible strain sensors (PFSS) with high stretchability and an excellent recoverability.

The researchers first synthesized a bifunctional monomer, hydrolyzably hindered urea acrylate, to create a crosslinked polymer network, preventing the dissolution of printed parts in the uncured resin. 3-D printed scaffolds can be hydrolyzed in hot water, which provides an attractive option for sacrificial molds. They then cast polyurethane/carbon nanotubes composites in molds to prepare flexible sensors as the PFSS. This PFSS exhibited a good pressure sensitivity (0.111 kPa-1) at the low compressive strain.

The resistance response signals were stable after 100 cycles of 60% mechanical loads with high cycle repeatability and stability. Additionally, the researchers demonstrated the practical applications of PFSS for in situ human motion detection including gait analysis and finger motion, proving it a promising material for smart wearable device preparation.

This study showed that the sacrificial molding process has great potential for user-specific stretchable wearable devices.

Scientists improve sensitivity and stretchability of room-temperature liquid metal-based sensor

More information:

Shuqiang Peng et al. Tailored and Highly Stretchable Sensor Prepared by Crosslinking an Enhanced 3D Printed UV‐Curable Sacrificial Mold, Advanced Functional Materials (2020). DOI: 10.1002/adfm.202008729

Provided by

Chinese Academy of Sciences

Citation:

Researchers prepare tailored and wearable sensor via 3-D printed UV-curable sacrificial mold (2020, December 30)

retrieved 30 December 2020

from https://techxplore.com/news/2020-12-tailored-wearable-sensor-d-uv-curable.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.