Scientists at Japan’s Nagoya University and the National Institute for Materials Science have found that a simple one-drop approach is cheaper and faster for tiling functional nanosheets together in a single layer. If the process, described in the journal ACS Nano, can be scaled up, it could advance development of next-generation oxide electronics.

“Drop casting is one of the most versatile and cost-effective methods for depositing nanomaterials on a solid surface,” says Nagoya University materials scientist Minoru Osada, the study’s corresponding author. “But it has serious drawbacks, one being the so-called coffee-ring effect: a pattern left by particles once the liquid they are in evaporates. We found, to our great surprise, that controlled convection by a pipette and a hotplate causes uniform deposition rather than the ring-like pattern, suggesting a new possibility for drop casting.”

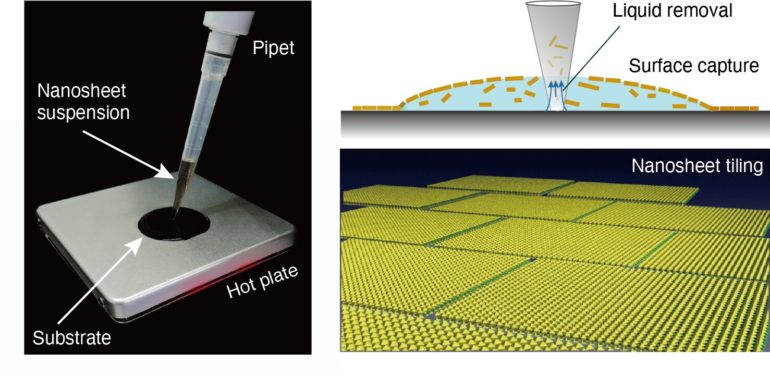

The process Osada describes is surprisingly simple, especially when compared to currently available tiling techniques, which can be costly, time-consuming, and wasteful. The scientists found that dropping a solution containing 2-D nanosheets with a simple pipette onto a substrate heated on a hotplate to a temperature of about 100°C, followed by removal of the solution, causes the nanosheets to come together in about 30 seconds to form a tile-like layer.

Analyses showed that the nanosheets were uniformly distributed over the substrate’s surface, with limited gaps. This is probably a result of surface tension driving how particles disperse, and the shape of the deposited droplet changing as the solution evaporates.

The scientists used the process to deposit particle solutions of titanium dioxide, calcium niobate, ruthenium oxide, and graphene oxide. They also tried different sizes and shapes of a variety of substrates, including silicon, silicon dioxide, quartz glass, and polyethylene terephthalate (PET). They found they could control the surface tension and evaporation rate of the solution by adding a small amount of ethanol.

Furthermore, the team successfully used this process to deposit multiple layers of tiled nanosheets, fabricating functional nanocoatings with various features: conducting, semiconducting, insulating, magnetic and photochromic.

Novel metal-organic framework nanosheets developed for anticorrosive coating

More information:

Yue Shi et al. Single Droplet Assembly for Two-Dimensional Nanosheet Tiling, ACS Nano (2020). DOI: 10.1021/acsnano.0c05434

Citation:

Nanosheet-based electronics could be one drop away (2021, January 8)

retrieved 11 January 2021

from https://phys.org/news/2021-01-nanosheet-based-electronics.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.