Researchers have fabricated a magnetically driven rotary microfilter that can be used to filter particles inside a microfluidic device. They made the tiny turning filter by creating a magnetic material that could be used with a very precise 3D printing technique known as two-photon polymerization.

Microfluidic devices, also known as lab-on-a-chip devices, can be used to perform multiple laboratory functions inside a chip that usually measures a few square centimeters or less. These devices contain intricate networks of microfluidic channels and are becoming more and more complex. They may be useful for a variety of applications such as screening molecules for therapeutic potential or performing blood tests that detect disease.

“By changing the direction of external magnetic field, the microfilter we made can be remotely manipulated on demand to either filter certain-sized particles or to allow them all to pass,” said Dong Wu, a member of the research team from the University of Science and Technology of China. “This functionality could be used for many types of chemical and biological studies performed in lab-on-a-chip devices, and importantly, makes it possible for the chips to be reused.”

In The Optical Society (OSA) journal Optics Letters, Wu, together with colleagues from the Hefei University of Technology and RIKEN Center for Advanced Photonics in Japan, show that their new rotary microfilter filters can sort particles in a microfluidic device with high performance.

“This filter could eventually be used to sort cells of different sizes for applications such as isolating circulating tumor cells for analysis or detecting abnormally large cells that may indicate disease,” said Chaowei Wang from University of Science and Technology of China. “With further development it might even be possible to use it in devices placed inside the body for cancer detection.”

A more versatile filter

Filters with micrometer-sized holes are often used in microfluidic chips as a passive way to sort particles or cells based on sizes of the holes. However, because the number and shape of holes in the filter cannot be dynamically changed, available devices lack the flexibility to sort different types of particles or cells on demand. To expand the usefulness of microfluidic devices, the researchers developed a filter that can freely switch between modes such as selective filtering and passing.

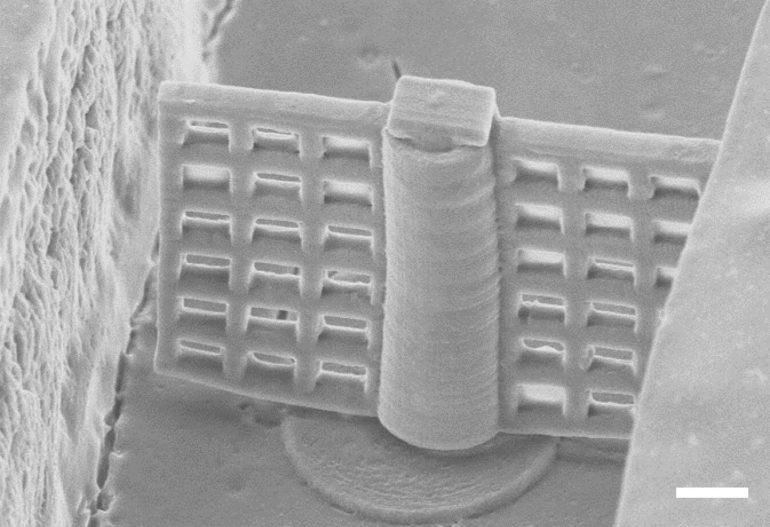

They created the new filter using two-photon polymerization, which uses a focused femtosecond laser beam to solidify, or polymerize, a liquid light-sensitive material known as photoresist. Thanks to two-photon absorption, the polymerization can be done in a very precise manner, enabling fabrication of complex structures on the micron scale.

To make the microfilter, the researchers synthesized magnetic nanoparticles and mixed them with the photoresist. Fabricating the rotary microfilter required them to optimize the laser power density, number of pulses and scanning intervals used for polymerization. After testing its magnetically driven properties on a glass slide, they integrated the microfilter into a microfluidic device.

Multiple filtering modes

To filter larger particles, a magnetic field perpendicular to the microchannel is applied. After the filtering process is complete, the large particles can be released by applying a magnetic field that is parallel to the microchannel, which will rotate the microfilter by 90°. The filtering process can then be repeated as needed.

The researchers verified the filtering performance of the filter using polystyrene particles with diameters of 8.0 and 2.5 microns that were mixed in an alcohol solution. “It was clear that particles smaller than the pore size easily passed through microfilter while bigger ones were filtered out,” said Chenchu Zhang from University of Science and Technology of China. “When in passing mode, any larger particles captured by the filter were washed away with the fluid, which prevents filter clogging and allows reuse of the microfilter.”

Magnetically propelled cilia power climbing soft robots and microfluidic pumps

More information:

Chaowei Wang et al, Magnetically driven rotary microfilter fabricated by two-photon polymerization for multimode filtering of particles, Optics Letters (2021). DOI: 10.1364/OL.428751

Provided by

The Optical Society

Citation:

Researchers 3D-print rotating microfilter for lab-on-a-chip applications (2021, June 15)

retrieved 15 June 2021

from https://phys.org/news/2021-06-3d-print-rotating-microfilter-lab-on-a-chip-applications.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.