In June of 2020, Boston Dynamics started selling its first commercial robot: Spot.

It was a big moment for the company. For most of its 30 year history, Boston Dynamics has been focused on research and development. Initially, Boston Dynamics received a lot of its funding from the U.S. military and DARPA. Later, it was financed by big-name owners including Google, SoftBank and most recently, Hyundai. All of these companies have tried to steer the robot maker on a path to commercialization, and Boston Dynamics is finally getting there.

“I expect that we will become a serial producer of novel robots with advanced capabilities. I think we’ll build, every, say three to five years, we’re going to roll out a new robot targeting a new industry,” says Robert Playter, CEO of Boston Dynamics.

But for now, Boston Dynamics is focusing on the inspection and warehouse industries with its robots Spot and Stretch.

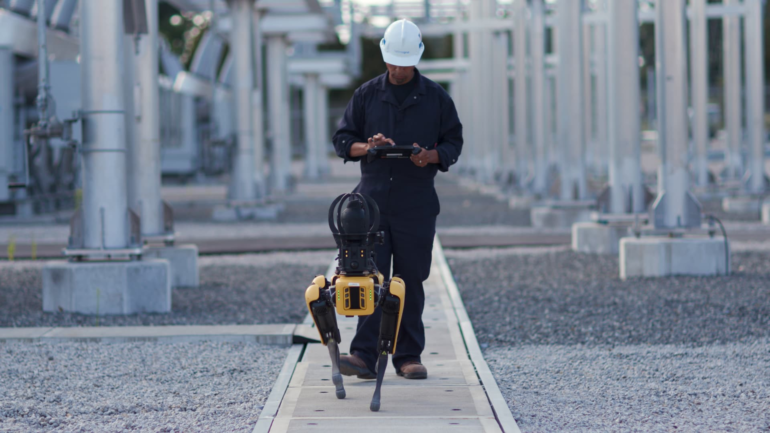

“The next big industry for Spot is really in this this market that we’re calling industrial sensing or dynamics sensing, which is where we have robots walking around places like manufacturing plants, chemical plants, utilities, installations, and using the robots to collect data on what’s happening in these facilities in an automated way,” says Zack Jackowski, chief engineer of the Spot product. “And this is really interesting, because once you start getting this highly repeatable, high quality data, you could start understanding these facilities and the efficiencies of them in new ways.”

So far, Spot has been used to do inspections at construction sites, oil rigs, nuclear plants, to check the vital signs of Covid-19 patients in hospitals, and even remind people to maintain social distance amid the pandemic. Boston Dynamics said it has sold several hundred Spot robots so far, with the entry level robot costing around $75,000.

The company’s other commercial robot, Stretch, focuses on the warehouse market.

“We see Stretch as ultimately a general purpose box moving machine that can be used anywhere in the warehouse,” says Playter. “Something like 800 million containers are shipped around the world each year. Many of those are full of boxes. There’s probably trillions of boxes that are loaded and unloaded by hand each year in the United States. It’s a huge job. It’s a mountain of material that has to get moved. Stretch is really power tools to help people move that that material.”

Stretch is made up of a few different parts. The robot uses a mobile base to move around tight spaces and go up loading ramps. An arm, gripper, vision cameras and sensors allow the robot to identify and handle a variety of different objects. Initially, the robot will be used for the loading and unloading of trucks.

Boston Dynamics says it expects Stretch to go on sale next year, though it would not provide a price point. Customers can also opt to purchase just the computer vision software that powers Stretch, which Boston Dynamics calls Pick. The company says it’s working with a few early adopters to test the robot, but would not say who those partners are.

Check out the video to learn more about Boston Dynamics’ history and the company’s plan to transition from R&D to commercialization.