An international research group has developed a new surface coating technology that is capable of significantly increasing electron emission in materials. Their breakthrough is expected to improve the production of high-efficiency electron sources and lead to increased performances in electron microscopes, electron beam lithography systems and synchrotron radiation facilities. The research was published in the journal Applied Physics Letters on April 3, 2023.

Free electrons are those not bound to a specific atom or molecule, wondering freely within a material. They play a vital role in a wide range of applications, from photoreactors and microscopes to accelerators.

One property that measurers the performance of free electrons is work function: the minimum energy required for electrons to escape from a materials surface into a vacuum. Materials with a low work function require less energy to remove electrons and make them free to move around; whereas materials with a high work function need more energy to remove electrons.

A lower work function is critical for enhancing the performance of electron sources and contributes to the development of advanced materials and technologies that can have practical applications in various fields, such as electron microscopy, accelerator science, and semiconductor manufacturing.

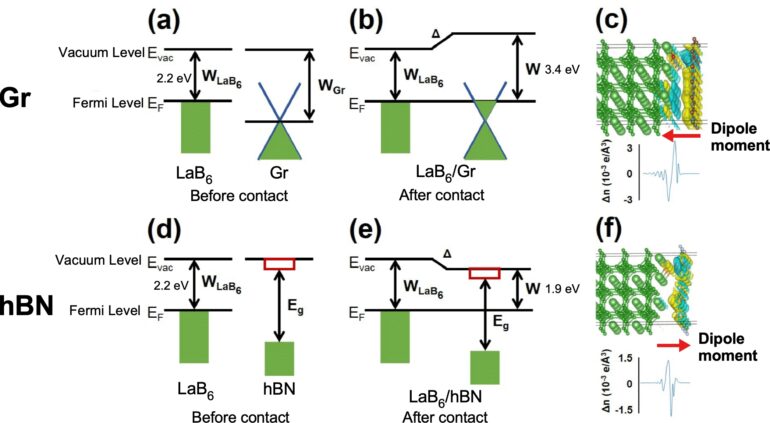

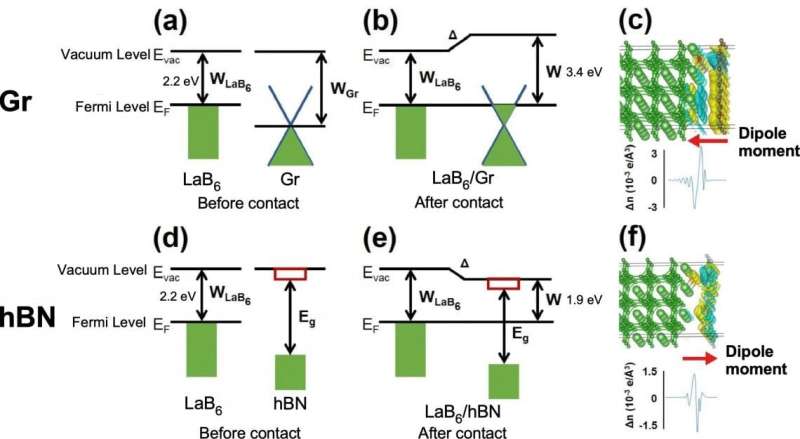

A schematic diagram of the work function modulation mechanism by graphene and hBN coating. When LaB6 and coating material come into contact by coating, their Fermi levels (EF) become equal. In the case of coating LaB6 with graphene ((a), (b)), the work function W after graphene coating is larger than the original work function of LaB6, WLaB6. On the other hand, in the case of hBN coating ((d), (e)), the work function W after hBN coating is lower than WLaB6. Figures (c) and (f) show the redistribution of charges by first-principles calculation. © Hisato Yamaguchi et al

Currently, hexaboride lanthanum (LaB6) is widely employed for electron sources because of its high stability and durability. To improve the efficiency of LaB6, the research group turned to hexagonal boron nitride (hBN), a versatile chemical compound that is thermally stable, possesses a high melting point and is very useful in harsh environments,

“We discovered that coating LaB6 with hBN lowered the work function from 2.2 eV to 1.9 eV and increased electron emission,” said Shuichi Ogawa, co-author of the study and current associate professor at Nihon University (formerly at Tohoku University’s Institute of Multidisciplinary Research for Advanced Materials).

Photoemission electron microcopy and thermionic emission electron microscopy performed by the group confirmed the lower work function compared to non-coated and graphene coated regions.

Looking ahead, Ogawa and his colleagues hope to hone the coating technique. “We still need to develop a technique for coating hBN onto the non-oxidized surface of LaB6, as well as a way to coat LaB6 electron sources with a pointed triangular shape.”

More information:

Hisato Yamaguchi et al, Work function lowering of LaB6 by monolayer hexagonal boron nitride coating for improved photo- and thermionic-cathodes, Applied Physics Letters (2023). DOI: 10.1063/5.0142591

Citation:

New surface coating technology increases materials’ electron emission seven-fold (2023, May 12)