The 3D printing company Desktop Metal has just announced the release of Forust, a new tool using wood to 3D print objects. The company, founded in 2019, focuses on 3D printing for interior design. With printing methods deemed “non-destructive”, they haven’t come under much scrutiny for safety or environmental concerns, making them an attractive prospect for acquisition.

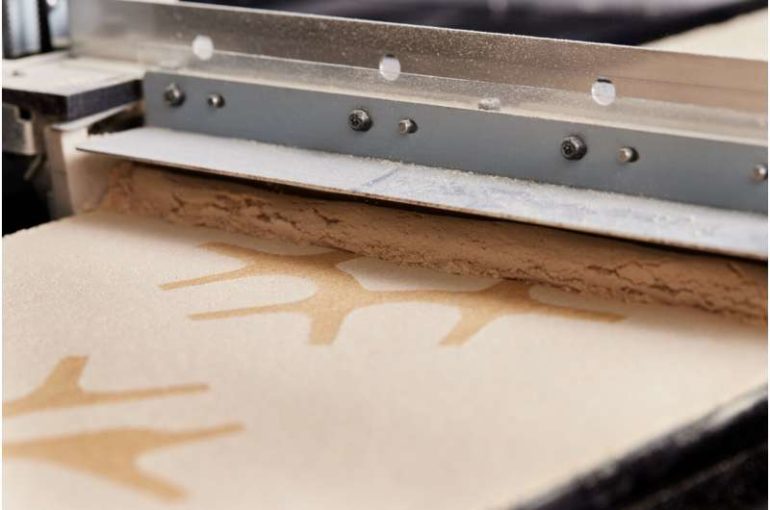

Indeed, according to a filing back in October of 2020, the company’s gross assets acquisition showed a price of $2.5 million USD, including a $2 million in cash considerations. Now, Desktop Metal has introduced Forust as its new portfolio manufacturing process. The technology uses cellulose dust and lignin, byproducts from both the paper and wood industries.

Lauding Desktop Metal, Forust CEO Andrew Jeffery states that the interior design company enables architects, designers and manufacturers to utilize design-forward technology in order to re-consider the use of wood waste streams, from just one piece to over a million pieces. In turn, Jeffery reports that Forust does its part by offering sustainable, 3D-printed wood designs for both businesses and consumers to develop beautiful, strong wood products suited for a variety of industries, including consumer home goods, furniture and interior design.

Beginning now, the company will also offer samples for designs online. Their list of products will include architectural accents, home products such as bowls and flower pots and furniture pieces.

In fact, Desktop Metals’ CEO Ric Fulop says that many types of plastics and polymers used today can now be replaced with sustainably manufactured and cost-effective wood parts. Many of these products can even be put to use toward high-end activities and locations, such as consumer electronics, aviation, boats, instruments, home goods and—in the future—for flooring and exterior roofing.

Alongside Forust, Desktop Metal’s recent filing reports that the company has also acquired a new technology asset from the sheet metal printing company Figur Machine Tools for $3.5 million. These activities both followed up Desktop Metal’s announcement of intentions to go public back in August of 2020, for a value of $2.5 billion.

From rapid prototyping to output at scale, two metal 3D printing systems are announced

More information:

Desktop Metal Develops New Additive Manufacturing Process for Volume Production of Sustainable, End-Use Wood Parts, www.businesswire.com/news/home/20210506005551/en/

2021 Science X Network

Citation:

3D printing company Desktop Metal will now use wood to print (2021, May 8)

retrieved 8 May 2021

from https://techxplore.com/news/2021-05-3d-company-desktop-metal-wood.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.