A team led by scientists at the Department of Energy’s Oak Ridge National Laboratory identified and successfully demonstrated a new method to process a plant-based material called nanocellulose that reduced energy needs by a whopping 21%. The approach was discovered using molecular simulations run on the lab’s supercomputers, followed by pilot testing and analysis.

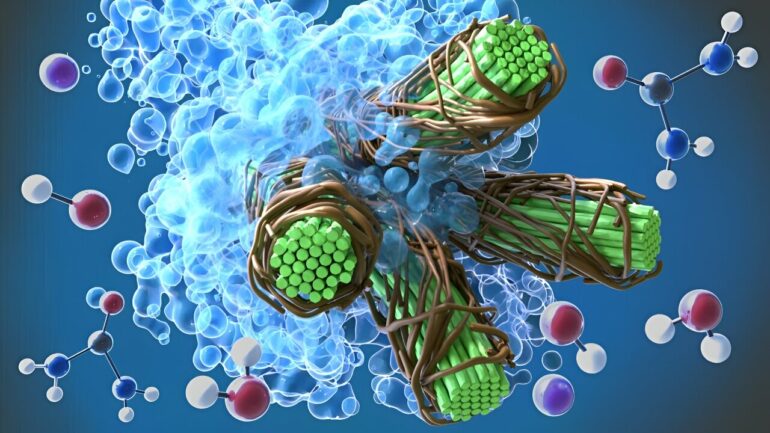

The method, leveraging a solvent of sodium hydroxide and urea in water, can significantly lower the production cost of nanocellulosic fiber—a strong, lightweight biomaterial ideal as a composite for 3D-printing structures such as sustainable housing and vehicle assemblies. The findings support the development of a circular bioeconomy in which renewable, biodegradable materials replace petroleum-based resources, decarbonizing the economy and reducing waste.

Colleagues at ORNL, the University of Tennessee, Knoxville, and the University of Maine’s Process Development Center collaborated on the project that targets a more efficient method of producing a highly desirable material. Nanocellulose is a form of the natural polymer cellulose found in plant cell walls that is up to eight times stronger than steel.

The scientists pursued more efficient fibrillation: the process of separating cellulose into nanofibrils, traditionally an energy-intensive, high-pressure mechanical procedure occurring in an aqueous pulp suspension.

The researchers tested eight candidate solvents to determine which would function as a better pretreatment for cellulose. They used computer models that mimic the behavior of atoms and molecules in the solvents and cellulose as they move and interact.

The approach simulated about 6 million atoms, giving scientists an understanding of the complex process without the need for initial, time-consuming physical work in the lab.

The simulations developed by researchers with the UT-ORNL Center for Molecular Biophysics, or CMB, and the Chemical Sciences Division at ORNL were run on the Frontier exascale computing system—the world’s fastest supercomputer for open science. Frontier is part of the Oak Ridge Leadership Computing Facility, a DOE Office of Science user facility at ORNL.

“These simulations, looking at every single atom and the forces between them, provide detailed insight into not just whether a process works, but exactly why it works,” said project lead Jeremy Smith, director of the CMB and a UT-ORNL Governor’s Chair.

Once the best candidate was identified, the scientists followed up with pilot-scale experiments that confirmed the solvent pretreatment resulted in an energy savings of 21% compared to using water alone, as described in an article published in the Proceedings of the National Academy of Sciences.

With the winning solvent, researchers estimated electricity savings potential of about 777 kilowatt hours per metric ton of cellulose nanofibrils, or CNF, which is roughly the equivalent to the amount needed to power a house for a year. Testing of the resulting fibers at the Center for Nanophase Materials Science, a DOE Office of Science user facility at ORNL, found similar mechanical strength and other desirable characteristics compared with conventionally produced CNF.

“We targeted the separation and drying process since it is the most energy-intense stage in creating nanocellulosic fiber,” said Monojoy Goswami of ORNL’s Carbon and Composites group. “Using these molecular dynamics simulations and our high-performance computing at Frontier, we were able to accomplish quickly what might have taken us years in trial-and-error experiments.”

The right mix of materials, manufacturing

“When we combine our computational, materials science and manufacturing expertise and nanoscience tools at ORNL with the knowledge of forestry products at the University of Maine, we can take some of the guessing game out of science and develop more targeted solutions for experimentation,” said Soydan Ozcan, lead for the Sustainable Manufacturing Technologies group at ORNL.

The project is supported by both the DOE Office of Energy Efficiency and Renewable Energy’s Advanced Materials and Manufacturing Technologies Office, or AMMTO, and by the partnership of ORNL and U-Maine known as the Hub & Spoke Sustainable Materials & Manufacturing Alliance for Renewable Technologies Program, or SM2ART.

The SM2ART program focuses on developing an infrastructure-scale factory of the future, where sustainable, carbon-storing biomaterials are used to build everything from houses, ships and automobiles to clean energy infrastructure such as wind turbine components, Ozcan said.

“Creating strong, affordable, carbon-neutral materials for 3D printers gives us an edge to solve issues like the housing shortage,” Smith said.

It typically takes about six months to build a house using conventional methods. But with the right mix of materials and additive manufacturing, producing and assembling sustainable, modular housing components could take just a day or two, the scientists added.

The team continues to pursue additional pathways for more cost-effective nanocellulose production, including new drying processes.

Follow-up research is expected to use simulations to also predict the best combination of nanocellulose and other polymers to create fiber-reinforced composites for advanced manufacturing systems such as the ones being developed and refined at DOE’s Manufacturing Demonstration Facility, or MDF, at ORNL.

The MDF, supported by AMMTO, is a nationwide consortium of collaborators working with ORNL to innovate, inspire and catalyze the transformation of U.S. manufacturing.

More information:

Shih-Hsien Liu et al, Molecular-level design of alternative media for energy-saving pilot-scale fibrillation of nanocellulose, Proceedings of the National Academy of Sciences (2024). DOI: 10.1073/pnas.2405107121

Provided by

Oak Ridge National Laboratory

Citation:

Molecular simulations and supercomputing shed light on energy-saving biomaterials (2024, September 6)