Modern beer production is a US$117 billion business in the United States, with brewers producing over 170 million barrels of beer per year. The brewing process is time- and energy-intensive, and each step generates large amounts of waste.

Solid components such as used grains and yeast from this waste end up in landfills, where harmful compounds can leach into the soil. Brewing wastewater that makes it into aquatic ecosystems can contaminate streams and lakes, decrease oxygen levels in those environments and threaten organisms.

To keep this waste from going into the environment, scientists like me are exploring how to manufacture beer brewing waste into useful products. I’m a chemist, and my research team and I are interested in figuring out how to recycle and repurpose brewery waste into tiny particles that can be used to make new types of prescription drugs.

The brewing process

The brewing process takes raw cereal grain – usually from barley – and converts its starch and proteins into simpler chemicals by malting. Brewers initiate this process by adding water, which wakes the seed from dormancy, and then keeping the seeds at a controlled temperature to sprout the grain.

During this time, important enzymes are released that can convert the starch and proteins in the grains to fermentable sugars and amino acids. They then heat up the resulting product, called the malt, to dry it out and stop further sprouting. After this malting process, they add hot water and mash the malt to release the compounds that give the beer its iconic flavor.

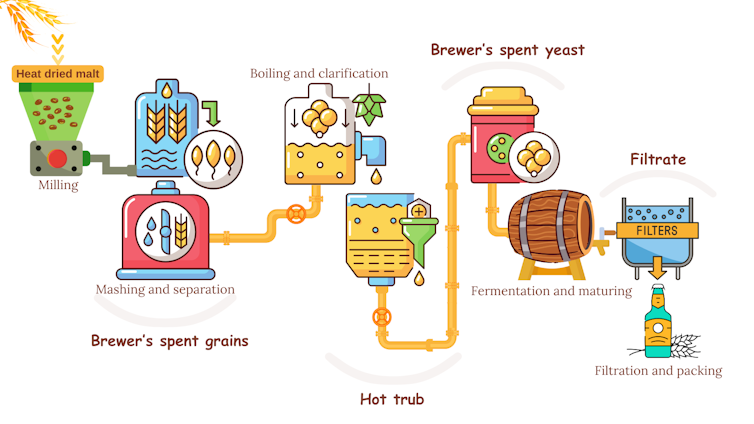

The brewing process produces waste at four main stages.

Alcina Johnson Sudagar, CC BY-SA

The brewers then separate the sweet malt extract, called wort, and the leftover solid is removed as waste, called brewer’s spent grains. About 30% of the weight of the raw grain ends up as spent grain waste. This waste is either used as animal feed or discarded. About 30 million tons of spent grain is generated annually.

Brewers add a cone-shaped flower of the Humulus lupulus plant, called hops, to the wort, then boil and clarify it. The hops flower is the key ingredient that gives beer its bitterness and aroma. The undissolved hops and proteins get collected during clarification to form hot trub, the second major waste from breweries. Roughly 85% of the hops are removed as waste material.

The clear wort is then cooled and fermented by adding yeast. The yeast filtered out after fermentation, called brewer’s spent yeast, forms the third type of waste that breweries generate. The spent yeast is one of the major byproducts of the brewing industry. This waste has a large quantity of water and solid material: 100 liters of beer generate 2 to 4 kilograms (4.4 to 8.8 lbs.) of spent yeast.

Finally, the fermented beer is filtered before entering the production line, where the beer is bottled for consumption. The wastewater generated at this last stage forms the…