The word “local” has become synonymous with sustainability, whether it’s food, clothes or the materials used to construct buildings. But while consumers can probably go to a local lumberyard to buy lumber from sustainably grown trees cut at nearby sawmills, no one asks for local glass.

If they did, it would be hard to give an answer.

The raw materials that go into glass – silica sand, soda ash and limestone – are natural, but the sources of those materials are rarely known to the buyer.

The process by which sand becomes sheets of glass is often far from transparent. The sand, which makes up over 70% of glass, could come from a faraway riverbed, lakeshore or inland limestone outcrop. Sand with at least 95% silica content is called silica sand, and only the purest is suitable for architectural glass production. Such sand is found in limited areas.

Klondike Park, outside St. Louis, was once a mine for St. Peter sandstone, used in glass production. This is one of the few U.S. locations with 99% pure silica.

Aki Ishida

If the glass is colorless, its potential sources are even more limited, because colorless low-iron glass – popularized by Apple’s flagship stores and luxury towers around the world – requires 99% pure silica sand.

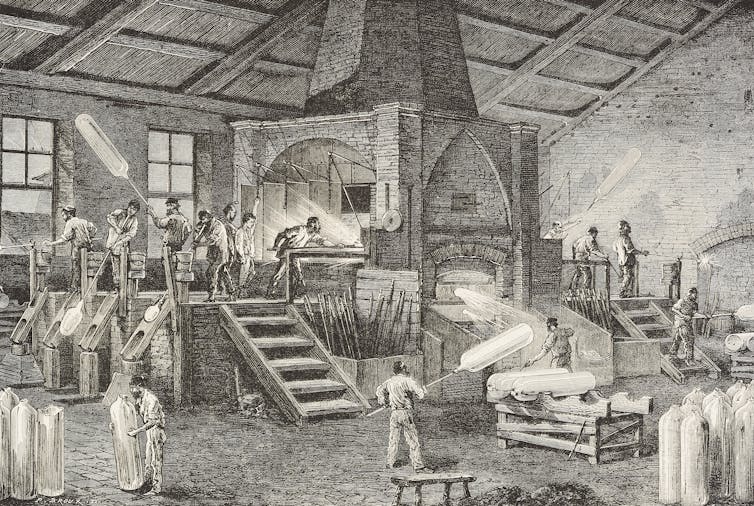

Glass production in Venice

The mysteries of glass production have historic precedent that can be traced back to trade secrets of the Venetian Empire.

Venice, particularly the island of Murano, became the center for glass production largely due to its strategic location for importing raw materials and production know-how and exporting coveted glass objects.

From the 11th to the 16th centuries, the secrets of glassmaking were protected by the Venetians until three glassmakers were smuggled out by King Louis XIV of France, who applied the technology to create the Palace of Versailles’ Hall of Mirrors.

The Palace of Versailles’ famed Hall of Mirrors was made by glass artisans trained by the Venetians.

Myrabella/Wikimedia Commons, CC BY-SA

Venice was an otherwise unlikely location for glassmaking.

Neither the primary materials of sand and soda ash (sodium carbonate) nor the firewood for the medieval Venetian glassmakers were found in the city’s immediate vicinity. They were transported from the riverbeds of the Ticino River in Switzerland and the Agide River, which flows from the Austria-Switzerland border to the Adriatic Sea south of Venice. Soda ash, which is needed to lower the melting point of silica sand, was brought from Syria and Egypt.

So Venetian glass production was not local; it was dependent on precious resources imported from afar on ships.