Gallium nitride crystals are a promising material for the development of next-generation power semiconductor devices. NIMS and the Tokyo Tech developed a technique for growing high-quality GaN crystals with considerably fewer defects than those grown using existing techniques. Unlike conventional techniques in which a crystal is grown directly in a solution, this technique uses a substrate coated with thin-alloy-film that prevents undesirable inclusions of the solution from being trapped within the growing crystal.

GaN semiconductors are able to withstand stronger electrical currents and higher voltages than silicon semiconductors. These advantages have led to intensive R&D on GaN for use in next-generation power semiconductor devices for use in vehicles and other purposes. However, conventional GaN single crystal growth techniques, in which a gaseous raw material is sprayed onto a substrate, have a fundamental drawback: they cause the formation of many atomic-scale defects (including dislocations) in the crystal. When GaN crystals with dislocations are integrated into power devices, the leak current passes through the devices and causes damages them. To address this issue, intensive efforts have been made to develop two alternative crystal synthesis techniques: the ammonothermal method and the sodium flux method. In both methods, a crystal is grown in a solution containing raw materials for crystal growth. While the Na flux method have proven to be effective in minimizing the formation of dislocations, a new problem has been identified: a growing crystal incorporates inclusions (clumps of the constituents of the solution).

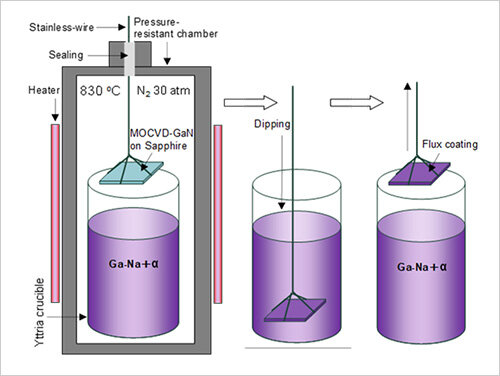

In this project, the researchers grew a GaN crystal while successively coating the GaN-seed substrate with a liquid alloy composed of raw materials for crystal growth (i.e., gallium and sodium), thereby preventing inclusions from being trapped within the growing crystal. In addition, this technique was found to be effective in significantly reducing the formation of dislocations, resulting in the synthesis of high-quality crystals. This technique allows the fabrication of a high-quality GaN substrate through a very simple process within approximately one hour.

The technique they developed may offer a new method of producing high-quality GaN substrates for use in next-generation power semiconductor devices. The researchers are currently verifying its effectiveness by growing small crystals. In future studies, they plan to develop it into a practical technique that will enable the synthesis of larger crystals.

Development of a new low-cost gallium nitride (GaN) crystal manufacturing device

More information:

Yelim Song et al. High-Quality GaN Crystal Growth Using Flux-Film-Coated LPE with Na Flux, Crystal Research and Technology (2020). DOI: 10.1002/crat.202000042

Provided by

National Institute for Materials Science

Citation:

Development of a new technique for growing high-quality gallium nitride crystals (2020, December 23)

retrieved 26 December 2020

from https://phys.org/news/2020-12-technique-high-quality-gallium-nitride-crystals.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.