Water pollution is a growing concern globally, with research estimating that chemical industries discharge 300-400 megatonnes (600-800 billion pounds) of industrial waste into bodies of water each year.

As a team of materials scientists, we’re working on an engineered “living material” that may be able to transform chemical dye pollutants from the textile industry into harmless substances.

Water pollution is both an environmental and humanitarian issue that can affect ecosystems and human health alike. We’re hopeful that the materials we’re developing could be one tool available to help combat this problem.

Engineering a living material

The “engineered living material” our team has been working on contains programmed bacteria embedded in a soft hydrogel material. We first published a paper showing the potential effectiveness of this material in Nature Communications in August 2023.

The hydrogel that forms the base of the material has similar properties to Jell-O – it’s soft and made mostly of water. Our particular hydrogel is made from a natural and biodegradable seaweed-based polymer called alginate, an ingredient common in some foods.

The alginate hydrogel provides a solid physical support for bacterial cells, similar to how tissues support cells in the human body. We intentionally chose this material so that the bacteria we embedded could grow and flourish.

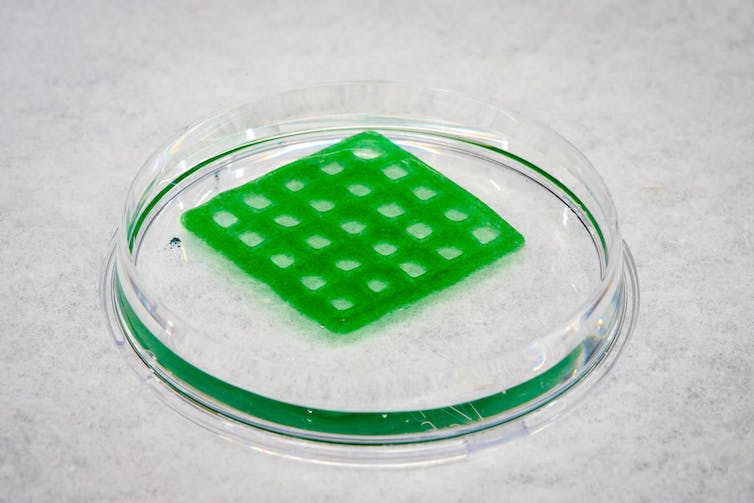

The grid shape of the material helps the bacteria take in carbon dioxide.

David Baillot/UC San Diego Jacobs School of Engineering, CC BY-NC-ND

We picked the seaweed-based alginate as the material base because it’s porous and can retain water. It also allows the bacterial cells to take in nutrients from the surrounding environment.

After we prepared the hydrogel, we embedded photosynthetic – or sunlight-capturing – bacteria called cyanobacteria into the gel.

The cyanobacteria embedded in the material still needed to take in light and carbon dioxide to perform photosynthesis, which keeps them alive. The hydrogel was porous enough to allow that, but to make the configuration as efficient as possible, we 3D-printed the gel into custom shapes – grids and honeycombs. These structures have a higher surface-to-volume ratio that allow more light, CO₂ and nutrients to come into the material.

The cells were happy in that geometry. We observed higher cell growth and density over time in the alginate gels in the grid or honeycomb structures when compared with the default disc shape.

Cleaning up dye

Like all other bacteria, cyanobacteria has different genetic circuits, which tell the cells what outputs to produce. Our team genetically engineered the bacterial DNA so that the cells created a specific enzyme called laccase.

The laccase enzyme produced by the cyanobacteria works by performing a chemical reaction with a pollutant that transforms it into a form that’s no longer functional. By breaking the chemical…