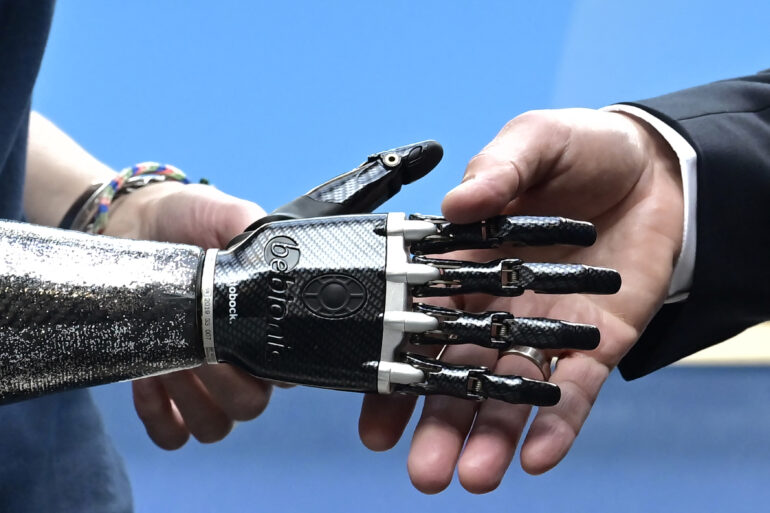

Three-dimensional printing is transforming medical care, letting the health care field shift from mass-produced solutions to customized treatments tailored to each patient’s needs. For instance, researchers are developing 3D-printed prosthetic hands specifically designed for children, made with lightweight materials and adaptable control systems.

These continuing advancements in 3D-printed prosthetics demonstrate their increasing affordability and accessibility. Success stories like this one in personalized prosthetics highlight the benefits of 3D printing, in which a model of an object produced with computer-aided design software is transferred to a 3D printer and constructed layer by layer.

We are a biomedical engineer and chemist who work with 3D printing. We study how this rapidly evolving technology provides new options not just for prosthetics but for implants, surgical planning, drug manufacturing and other health care needs. The ability of 3D printing to make precisely shaped objects in a wide range of materials has led to, for example, custom replacement joints and custom-dosage, multidrug pills.

Better body parts

Three-dimensional printing in health care started in the 1980s with scientists using technologies such as stereolithography to create prototypes layer by layer. Stereolithography uses a computer-controlled laser beam to solidify a liquid material into specific 3D shapes. The medical field quickly saw the potential of this technology to create implants and prosthetics designed specifically for each patient.

One of the first applications was creating tissue scaffolds, which are structures that support cell growth. Researchers at Boston Children’s Hospital combined these scaffolds with patients’ own cells to build replacement bladders. The patients remained healthy for years after receiving their implants, demonstrating that 3D-printed structures could become durable body parts.

As technology progressed, the focus shifted to bioprinting, which uses living cells to create working anatomical structures. In 2013, Organovo created the world’s first 3D-bioprinted liver tissue, opening up exciting possibilities for creating organs and tissues for transplantation. But while significant advances have been made in bioprinting, creating full, functional organs such as livers for transplantation remains experimental. Current research focuses on developing smaller, simpler tissues and refining bioprinting techniques to improve cell viability and functionality. These efforts aim to bridge the gap between laboratory success and clinical application, with the ultimate goal of providing viable organ replacements for patients in need.

Three-dimensional printing already has revolutionized the creation of prosthetics. It allows prosthetics makers to produce affordable custom-made devices that fit the patient perfectly. They can tailor prosthetic hands and limbs to each individual and easily replace them as a child grows….