Thin tissue grafts and flexible electronics have a host of applications for wound healing, regenerative medicine and biosensing. A new device inspired by an octopus’s sucker rapidly transfers delicate tissue or electronic sheets to the patient, overcoming a key barrier to clinical application, according to researchers at the University of Illinois at Urbana-Champaign and collaborators.

“For the last few decades, cell or tissue sheets have been increasingly used to treat injured or diseased tissues. A crucial aspect of tissue transplantation surgery, such as corneal tissue transplantation surgery, is surgical gripping and safe transplantation of soft tissues. However, handling these living substances remains a grand challenge because they are fragile and easily crumple when picking them up from the culture media,” said study leader Hyunjoon Kong, a professor of chemical and biomolecular engineering at Illinois.

Kong’s group, along with collaborators at Purdue University, the University of Illinois at Chicago, Chung-Ang University in South Korea, and the Korea Advanced Institute for Science and Technology, published their work in the journal Science Advances.

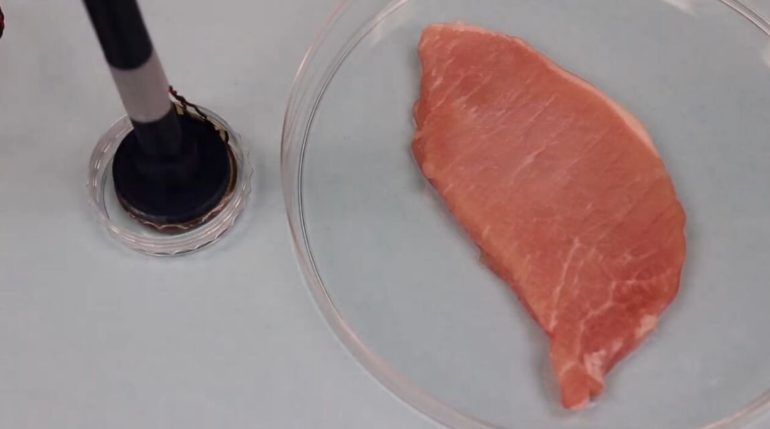

Current methods of transferring the sheets involve growing them on a temperature-sensitive soft polymer that, once transferred, shrinks and releases the thin film. However, this process takes 30-60 minutes to transfer a single sheet, requires skilled technicians and runs the risk of tearing or wrinkling, Kong said.

“During surgery, surgeons must minimize the risk of damage to soft tissues and transplant quickly, without contamination. Also, transfer of ultrathin materials without wrinkle or damage is another crucial aspect,” Kong said.

Seeking a way to quickly pick up and release the thin, delicate sheets of cells or electronics without damaging them, the researchers turned to the animal kingdom for inspiration. Seeing the way an octopus or squid can pick up both wet and dry objects of all shapes with small pressure changes in their muscle-powered suction cups, rather than a sticky chemical adhesive, gave the researchers an idea.

They designed a manipulator made of a temperature-responsive layer of soft hydrogel attached to an electric heater. To pick up a thin sheet, the researchers gently heat the hydrogel to shrink it, then press it to the sheet and turn off the heat. The hydrogel expands slightly, creating suction with the soft tissue or flexible electronic film so it can be lifted and transferred. Then they gently place the thin film on the target and turn the heater back on, shrinking the hydrogel and releasing the sheet.

The entire process takes about 10 seconds.

Next, the researchers hope to integrate sensors into the manipulator, to further take advantage of their soft, bio-inspired design.

“For example, by integrating pressure sensors with the manipulator, it would be possible to monitor the deformation of target objects during contact and, in turn, adjust the suction force to a level at which materials retain their structural integrity and functionality,” Kong said. “By doing so, we can improve the safety and accuracy of handling these materials. In addition, we aim to examine therapeutic efficacy of cells and tissues transferred by the soft manipulator.”

Octopus inspired adhesive patch works under water

More information:

Electrothermal soft manipulator enabling safe transport and handling of thin cell/tissue sheets and bioelectronic devices, Science Advances (2020). DOI: 10.1126/sciadv.abc5630 , advances.sciencemag.org/content/6/42/eabc5630

Provided by

University of Illinois at Urbana-Champaign

Citation:

Octopus-inspired sucker transfers thin, delicate tissue grafts and biosensors (2020, October 16)

retrieved 16 October 2020

from https://techxplore.com/news/2020-10-octopus-inspired-sucker-thin-delicate-tissue.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.