Researchers from Umeå University and Uppsala University have developed a new method to control the light emission of light-emitting electrochemical cells, in short LEC. The study is published in Advanced Materials.

The LEC light source is extremely thin, flexible and light and can now be easily modified to be up to 60% more efficient through simple and inexpensive changes to the materials in the active layer.

“We show that you can control the position where light is formed in the active layer through rational changes in material composition,” says Joan Ràfols-Ribé, postdoctoral fellow at the Department of Physics at Umeå University.

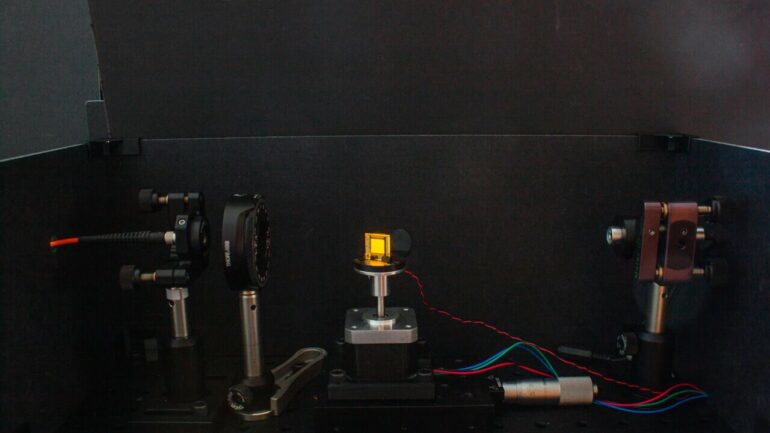

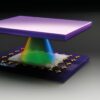

LECs are luminescent devices that emit light in response to an electrical current. They typically consist of a thin active layer of 100 to 500 nm (about 1,000 times thinner than the diameter of a human hair) of organic semiconductor material sandwiched between two electrodes, one being reflective and the other being transparent in order to let the light through.

The characteristic feature of LECs is that they reorganize into a light-emitting structure, resembling the structure of the light-emitting diodes (LEDs), once a voltage is applied between the two electrodes. The reorganization happens thanks to mobile ions, included in the active layer. Thanks to this reorganization, it is possible for electronic charges to enter the active layer from opposite electrodes and travel towards each other. Where these charges (of opposite sign) meet, they produce light.

“The position where this light emission takes place in the active layer, for example in the middle or close to one of the electrodes, is very important for the efficiency and the color of the emitted light. Until now, the LEC community has had very little control of where this light emission takes place and somewhat overlooked its influence,” says Joan Ràfols-Ribé.

Now, researchers from the Umeå University and Uppsala University demonstrate that it is possible to control the position of the light emission through rational changes to the material composition in the active layer. The researchers have fabricated three almost identical LECs in terms of materials, but with clearly distinct efficiencies differing up to 60%. This has been achieved through chemical changes to the so-called ion-transporter molecule, which is the compound that helps the ions to move within the active layer. These changes modify the capability of the electronic charges to travel through the material, which effectively changes the position where they meet within the active layer and thereby from where the light is generated.

Imagine two trains departing simultaneously and towards each other, one departing from Stockholm and one departing from Umeå. If the trains have the same speed, they meet in the middle—let’s say Sundsvall. But if we now consciously put a slower locomotive on the train from Stockholm, the trains will meet closer to Stockholm, such as Gävle.

“In the train analogy, it does not matter where the trains meet, but in an LEC it has an enormous effect and what we have succeeded in is gaining control over where the trains (i.e., where the charges) meet,” says Joan Ràfols-Ribé.

The take-home message from the study is that it is possible to control the position where light is generated in an LEC through rational and low-cost modifications of the materials in the active layer, resulting in a simple route to higher LEC performance.

More information:

Joan Ràfols‐Ribé et al, Controlling the Emission Zone by Additives for Improved Light‐Emitting Electrochemical Cells, Advanced Materials (2021). DOI: 10.1002/adma.202107849

Citation:

Flexible LEC components for efficient light emission (2022, March 17)