Photonic thermometers, which measure temperature using light, have the potential to revolutionize temperature measurement by being faster, smaller, and more robust than traditional thermometers. In essence, the sensors work by passing light into a structure that is sensitive to temperature. The light that comes out of the device gives scientists information about the temperature to which the sensor was exposed.

Someday, these tiny thermometers—and additional types of photonic sensors, which measure strain, humidity, acceleration, and other quantities—could be embedded into structures such as buildings or bridges as they are built. By measuring these properties as concrete or cement is setting, photonic sensors could give engineers valuable information about how the structure has formed, which can help them project how the structure will fare in the long term.

But one problem researchers haven’t yet solved is the best way to “interrogate” these photonic sensors—that is, to put light in and get light out. Traditional methods, which involve using lasers to create each frequency of light that enters the sensor, are difficult, slow, expensive, and bulky.

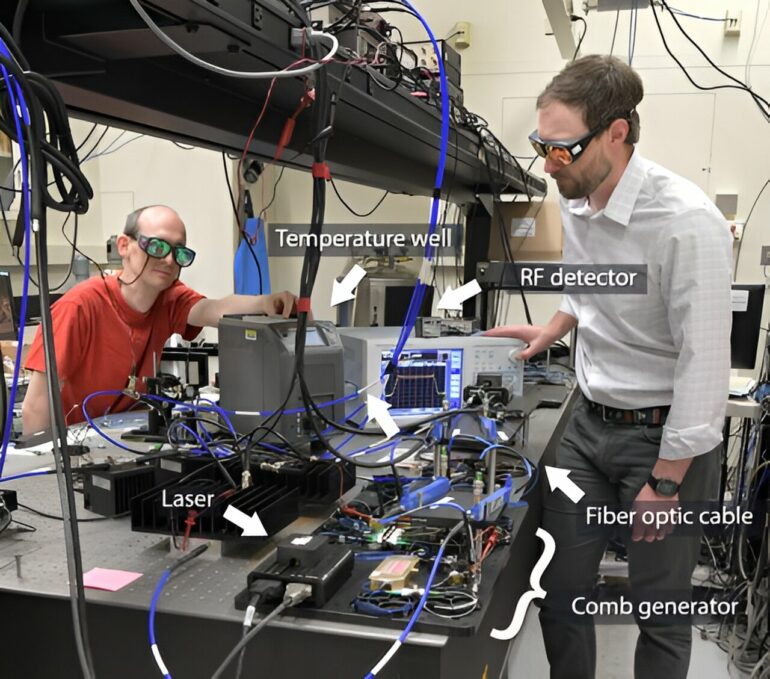

Now, researchers at the National Institute of Standards and Technology (NIST) have designed and tested a way to interrogate these sensors between 10 and 1,000 times faster than previous methods. They do this with something called a dual frequency comb system, employed in the past for tasks such as measuring trace amounts of greenhouse gases, but never before used with photonic thermometers.

The paper is published in the journal Optics Letters, and the proof-of-principle experiment takes them a step closer to commercialization of this technology.

“I was surprised by how well it worked,” said NIST’s Zeeshan Ahmed.

An additional benefit is that unlike traditional methods of getting light into and out of the sensors, the dual-comb system could support multiple photonic sensors at once, further reducing the size and cost of a future commercialized system.

Twenty questions

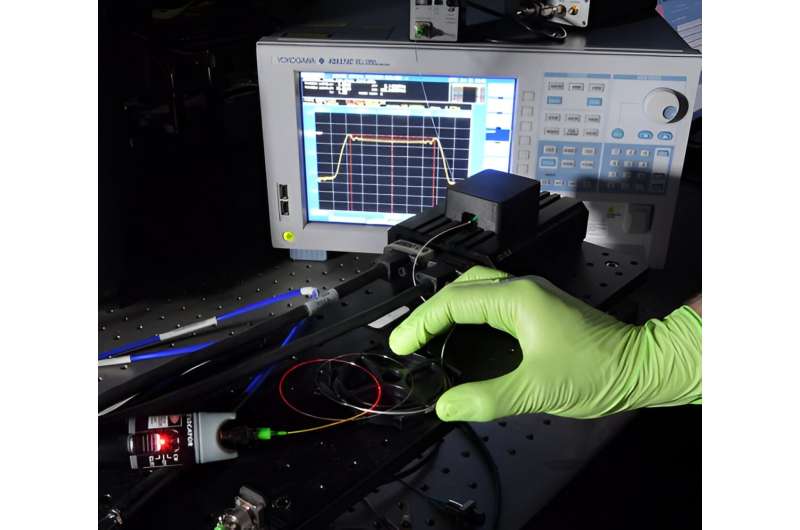

To use a photonic thermometer, researchers put light of many wavelengths into a fiber optic cable. That light interacts with a sensor of some kind—in this case, a type of grating consisting of a series of etch marks inside the fiber.

The way that the light interacts with the grating depends on the temperature The signal researchers get back from exposure to a temperature is a decrease in the amplitude—essentially a “dip”—in the light from one of the many wavelengths they put into the fiber. Which wavelength has the dip in it tells them which temperature the sensor is experiencing.

But how do you get the different wavelengths of light into the fiber?

Red laser light (for demonstration purposes) in a fiber optic cable. The photonic thermometer sensor sits inside the end of a cable like this one. © Jennifer Lauren Lee/NIST Demonstration of a “beat” pattern with two tuning forks that are almost identical but slightly off from each other in tone. If you play them at the same time, the tones will interfere with each other and create beating, where the sound gets alternately loud and soft. © Sean Kelley/NIST

One traditional way is by “sweeping” the laser, creating a series of different wavelengths one at a time and sending each one into the sensor. To maintain accuracy, researchers must do an additional step of comparing each wavelength to a standard that verifies that the wavelength they are generating is the one they intended.

“This is a slow way of doing things,” Ahmed said. “It’s a bit like playing Twenty Questions: You ask the sensor, is this wavelength the one with the dip in it? No. How about this one? No.”

Speed is particularly an issue for applications where the temperatures are changing rapidly—for example, when measuring microsecond (millionth of a second) temperature changes as a result of a radiation dose in radiation therapy, a type of cancer treatment that uses beams of light to heat up and kill cancer cells.

“The traditional ways of doing the scanning are not ideally suited for measuring rapid changes in temperature,” Ahmed said. “We can make it work, but it’s not perfect. So, where our team and I started talking was in that context of: How can we do really fast measurements but do them accurately?”

Combing through the possibilities

In the current project, the team accomplished this goal using devices called frequency combs—laser light consisting of a series of different wavelengths, each equally spaced from the others. (Wavelength and frequency are related to each other, sort of two sides of the same coin. The shorter the wavelength, the higher the frequency, and vice versa.) When viewing these wavelengths plotted on a graph, frequency combs look a bit like a hair combs, where each tooth is a discrete wavelength of light.

Combs can be used for all sorts of things, from building atomic clocks to acting as a reference, or a sort of ruler, for light that scientists can use to measure a light signal coming out of their experiment.

In this work, the researchers use one type of comb as a source of light—what they refer to as an “interrogator”—that they ferry into the photonic thermometer. The signal researchers are looking for is a decrease in the amount of light from a set of teeth corresponding to a particular temperature.

But it’s more complicated than that, because this system actually uses not one, but two frequency combs.

The photonic thermometer requires near-infrared light with wavelengths between about 1,520 nanometers (billionths of a meter) and 1,560 nanometers—a little bit too long for human eyes to see. (For context, visible light has wavelengths between about 400 and 800 nanometers.) When the teeth of the comb are so closely spaced—only thousandths of billionths of a meter difference between adjacent teeth—it’s hard to see the characteristic dip that tells researchers the temperature of the sensor.

To read the signal more easily, the researchers create a second comb that is almost an exact copy of the first—almost, but not quite. Researchers then combine the light from both combs and send it into the sensor.

Red laser light (for demonstration purposes) in a fiber optic cable. The photonic thermometer sensor sits inside the end of a cable like this one. © Jennifer Lauren Lee/NIST

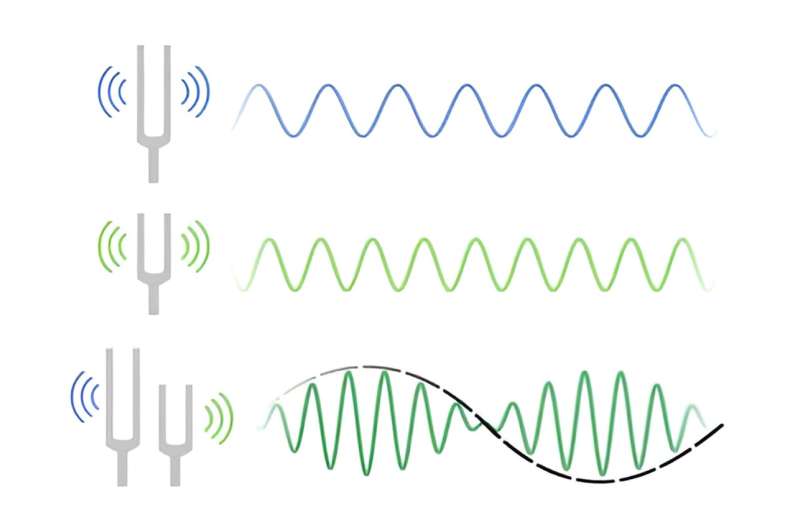

When the light from both combs is combined, their slightly offset frequencies create a beat pattern. Imagine you have two tuning forks generating tones that are almost identical but slightly off from each other. If you play them one after the other, they might sound the same to you. But if you play them together, their slightly different sounds interfere with one another. You can actually hear this difference—it sounds like a beat, with the tone getting louder and softer and louder and softer.

The amount by which the two combs’ teeth are offset from each other is in the regime of radio frequency (RF) waves, light with wavelengths on the order of meters. By using two optical combs, the researchers effectively create a single RF comb. The difference in wavelength between each pair of teeth in the optical combs is unique—and that difference creates each unique tooth in the RF comb.

Importantly, the “dip” in wavelength in the optical regime, which tells researchers what temperature the sensor is experiencing, also results in a “dip” in the RF output. That makes the drop in amplitude for a particular wavelength more noticeable.

“That’s the advantage of the dual-comb approach: It compresses all of that optical information into the RF regime where it’s easier to read out,” said NIST’s A.J. Fleisher.

That’s a Kelvin of a different color

To test how well their new scheme worked, the NIST team had to subject their sensor to a well-controlled temperature. So, while being interrogated by the laser light from the two optical frequency combs, the photonic sensor itself sits in a thermos-like container called a fixed-point cell.

Fixed-point cells are chunks of pure material that are either melting or freezing. While they’re undergoing that phase change, the temperature inside of them is stable and well known. Fixed-point cells are used to realize temperature according to the international system of units, or SI—the official international temperature scale.

“We used a fixed-point cell because we wanted temperature stability not to be the limiting factor in this experiment,” said NIST’s Tobias Herman. “That way, if something was shifting or moving or noisy, we could rule out the temperature bath as the source. It was just there to be a stage on which the interrogator could shine.”

With this setup, they were able to measure temperature to within ten thousandths of a kelvin, which the researchers say is sufficient for most industrial applications.

“It was pretty amazing,” Herman said. “I used a similar fiber when we were starting up a different research program, and I was sweeping the laser, a traditional mode of interrogation, and the rate that I was getting data was cripplingly slow. In contrast, the acquisition rate [data collection time] of this system was astonishing to me. But to be fair, I’m a temperature expert, not a combs expert. This is not my field, so I was ready for astonishment.”

In the coming months, the researchers hope to try the same setup with more than one sensor at a time. That’s the promise of the dual-comb photonic system: being able to have multiple thermometers as well as other photonic sensors in series, with the same laser light traveling through each one in turn.

“It’s very close to what we need it to be for commercialization,” Ahmed said. “We already met a lot of the metrics we need to meet, like the accuracy and speed of the measurements. This study shows that you can take a small version of a dual comb system and get good enough answers for the application space you need.”

More information:

Adam J. Fleisher et al, Dual electro-optic frequency comb photonic thermometry, Optics Letters (2023). DOI: 10.1364/OL.482838

Provided by

National Institute of Standards and Technology

Citation:

In a first, researchers apply dual frequency comb technology to photonic thermometers (2023, August 29)