Researchers have developed a new fabrication process that allows infrared (IR) glass to be combined with another glass and formed into complex miniature shapes. The technique can be used to create complex infrared optics that could make IR imaging and sensing more broadly accessible.

“Glass that transmits IR wavelengths is essential for many applications, including spectroscopy techniques used to identify various materials and substances,” said research team leader Yves Bellouard from Ecole Polytechnique Fédérale de Lausanne (EPFL) in Switzerland. “However, infrared glasses are difficult to manufacture, fragile and degrade easily in the presence of moisture.”

In the journal Optics Express, the researchers describe their new technique, which can be used to embed fragile IR glasses inside a durable silica matrix. The process can be used to create virtually any interconnected 3D shape with features measuring a micron or less. It works with a wide variety of glasses, offering a new way to fine-tune the properties of 3D optics with subtle combinations of glass.

“Our technique could open the door to a whole new range of new optical devices because it can be used to make infrared optical circuits and arbitrarily shaped IR micro-optics that were not previously possible because of the poor manufacturability of IR glass,” said Enrico Casamenti, first author of the paper. “These optics could be used, for example, for spectroscopy and sensing applications or to create an IR camera small enough to integrate into a smartphone.”

Merging materials

The new fabrication process grew out of previous work in which Bellouard’s research team collaborated with the team of Andreas Mortensen, also at EPFL, to develop a method for forming highly conductive metals inside an insulating 3D silica substrate.

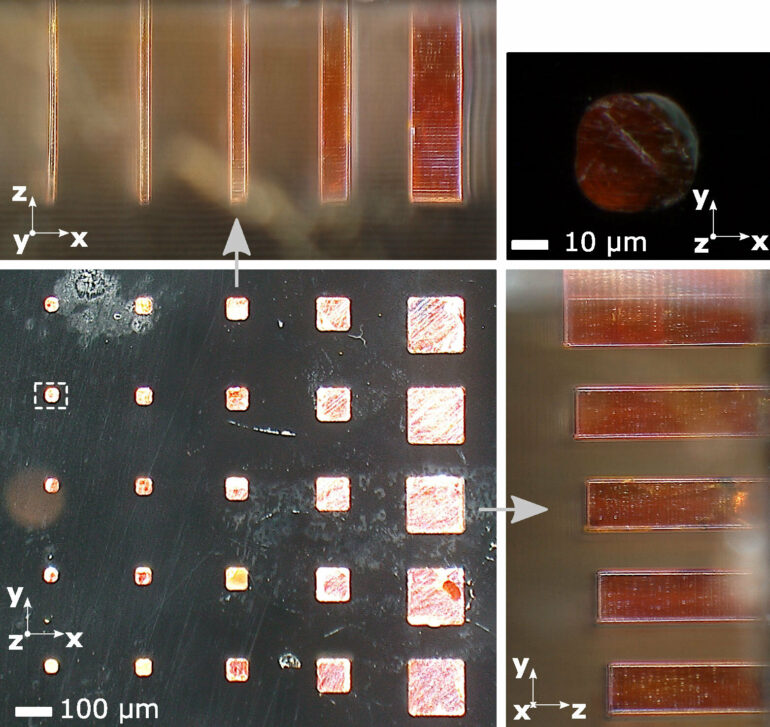

The team also fabricated the EPFL logo to show how that the method can be used to make complex 3D shapes. The top image shows dark-field illumination, and the bottom shows bright-field illumination. © Yves Bellouard, Ecole Polytechnique Fédérale de Lausanne

“Our team began seeking innovative ways to achieve broadband light confinement in arbitrarily shaped 3D optical circuits,” said Bellouard. “That’s when we decided to explore the possibility of modifying a process that we first demonstrated using metal so that it could be used to produce structures that combine two types of glass.”

For the new approach, the researchers start by creating an arbitrarily shaped 3D cavity inside a fused silica glass substrate using femtosecond laser-assisted chemical etching. This uses the pulsed beam of a femtosecond laser—which can be focused to a spot roughly one micrometer wide—to alter the glass structure in a way that allows the exposed areas to be removed with a chemical such as hydrofluoric acid.

Once this is done, the tiny cavity must be filled with another material to create a composite structure. The researchers accomplished this by using a miniaturized version of pressure-assisted casting, in which a second material is melted and pressurizing so that it can flow and solidify within the network of carved silica cavities. The second material can be a metal, glass or any material with a melting point below that of the carved silica substrate and that does not react with silica glass.

Creating complex optics

“Our fabrication method can be used to protect IR glass, opening new avenues for micro-scale infrared optical circuits that are fully integrated in another glass substrate,” said Bellouard. “Also, because fused silica and chalcogenide offer high refractive-index contrast, we can form these materials into IR waveguides that can transmit light much like optical fibers.”

The researchers demonstrated the new method by creating various complex shapes, including an EPFL logo, using chalcogenide IR glass and a silica glass substrate. They also showed, with the help of colleagues at ETH Zurich, that some of the structures they created could effectively be used for guiding mid-IR light emitted from a quantum cascade laser at 8 microns. Few optical components are available for this spectral range because of manufacturing challenges.

They are continuing to explore the capabilities of the new process in terms of combining different glasses and plan to test the composite parts in spectroscopy and other applications.

More information:

Enrico Casamenti et al, Glass-in-glass infiltration for 3D micro-optical composite components, Optics Express (2022). DOI: 10.1364/OE.451026

Citation:

Researchers develop glass-in-glass fabrication approach for making miniature IR optics (2022, April 7)