Focusing a tailored laser beam through transparent glass can create a tiny spot inside the material. Researchers at Tohoku University have reported on a way to use this small spot to improve laser material processing, boosting processing resolution.

Their findings were published in the journal Optics Letters.

Laser machining, like drilling and cutting, is vital in industries such as automotive, semiconductors, and medicine. Ultra-short pulse laser sources, with pulse widths from picoseconds to femtoseconds, enable precise processing at scales ranging from microns to tens of microns. But recent advancements demand even smaller scales, below 100 nanometers, which existing methods struggle to achieve.

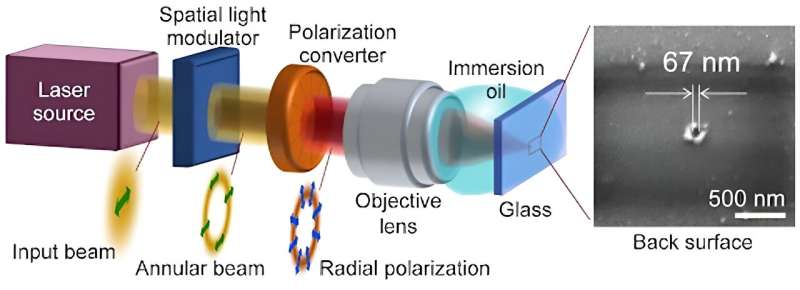

The researchers focused on a laser beam with radial polarization, known as a vector beam. This beam generates a longitudinal electric field at the focus, producing a smaller spot than conventional beams.

Scientists have identified this process as promising for laser processing. However, one drawback is that this field weakens inside the material due to light refraction at the air-material interface, limiting its use.

“We overcame this employing an oil immersion objective lens—something commonly found in biological microscopes—for laser processing glass substrates,” exclaims Yuichi Kozawa, an associate professor at Tohoku University’s Institute for Multidisciplinary Research for Advanced Materials (IMRAM) and co-author of the paper. “Because the immersion oil and glass have nearly identical refractive indices, the light that passes through them does not bend.”

Fabrication of an ablation crater with a size corresponding to ~1/16 of the wavelength by single-shot laser irradiation of the back surface of a glass with an annular-shaped radially polarized beam. © Y. Kozawa et al.

Further examination of the radially polarized beam behavior when focused with an annular shape revealed that the longitudinal field is greatly enhanced. This enhancement occurs because of total reflection at high converging angles on the back surface between the glass and air. By using an annular-shaped radially polarized beam, Kozawa and his colleagues created a small focal spot.

From there, they applied this method to laser process a glass surface with an ultra-short pulse laser beam. A single shot of the converted pulse on the back surface of a glass substrate created a hole with a diameter of 67 nanometers, about 1/16 of the laser beam’s wavelength.

“This breakthrough enables direct material processing with enhanced precision using the enhanced longitudinal electric field,” adds Kozawa. “It offers a simple approach to realize processing scales below 100 nm and opens new possibilities for laser nano-processing in various industries and scientific fields.”

More information:

Yukine Tsuru et al, Laser nanoprocessing via an enhanced longitudinal electric field of a radially polarized beam, Optics Letters (2024). DOI: 10.1364/OL.517382

Citation:

Researchers identify new method to boost laser processing resolution (2024, March 27)