With a powerful X-ray beam technique, researchers explore what makes soft materials such as toothpaste and hair gel relax. The insights they’ve gained can aid in the design of new consumer products and nanotechnologies.

Shaving gel, shampoo and a cup of yogurt. What do they all have in common? They’re all examples of soft materials, meaning materials that easily change shape when stress is applied.

In day-to-day life, soft materials are everywhere. Toothpaste, skin creams, tissues and coatings are just a few examples. Under stress, soft materials are able to change shape due to the tiny fluctuation of their particles, which are dynamic. This process of “relaxation” occurs randomly and at too small of a scale for scientists to easily pin down. But with the help of the Advanced Photon Source (APS), a U.S. Department of Energy (DOE) Office of Science user facility located at DOE’s Argonne National Laboratory, researchers are gaining a better understanding of these materials.

In a pair of recently published papers, two independent research teams successfully used a powerful X-ray beam technique at the APS to uncover new insights about the dynamics of soft materials. The information they learned can potentially aid in the design and development of a wide range of consumer products, including food products such as ice cream and gelatin desserts; personal care items such as moisturizers and shampoo; batteries; paints, foams and plastics used in manufacturing; and even nanotechnologies that make up coatings and systems for drug delivery.

“Understanding the dynamics of soft materials is important because we believe they have a direct and profound impact on properties we would want to control, such as viscosity and elasticity. Those properties control things like how soft a gel is or how fast a material flows,” said Argonne assistant physicist Qingteng Zhang, a co-author on both papers.

How researchers leveraged the power of X-rays

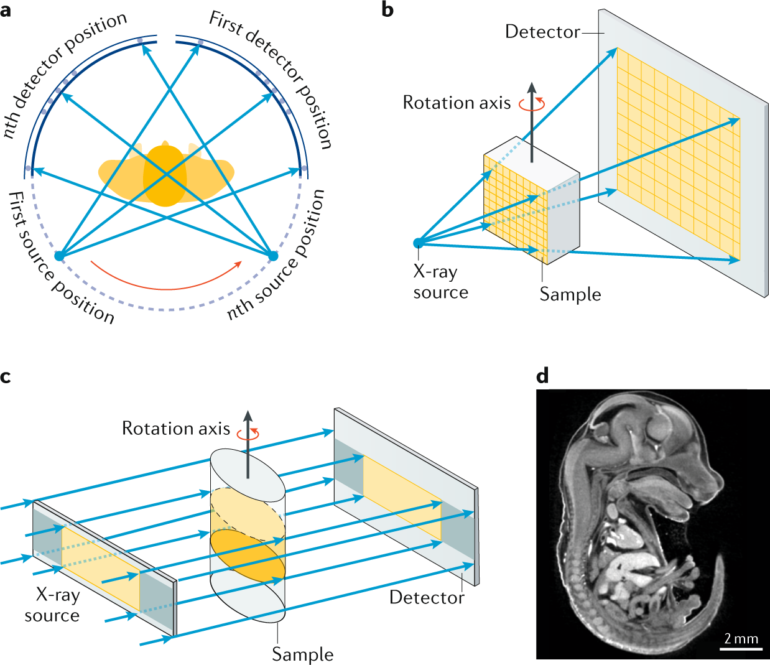

The X-ray beam technique both studies used is known as X-ray photon correlation spectroscopy (XPCS). Techniques like it enable scientists to probe the form and function of a wide range of materials at molecular and atomic scales.

XPCS is designed to reveal microscopic dynamics in areas as small as the diameter of a human hair. They can capture how dynamics change over time periods as short as a millionth of a second up to a couple of hours.

In the process, a material is exposed to X-ray beams. When the X-ray beams bounce off the moving particles in the sample, the properties of those X-rays, such as their direction of travel, change. Researchers can then detect these changes and use them to calculate how fast particles in the material are moving over different lengths, in turn learning about the dynamics of their structure.

Stress relaxation in hydrogels

One study that used XPCS was published in the Proceedings of the National Academy of Sciences by scientists at Argonne and Massachusetts Institute of Technology (MIT). Here, the technique was used to assess a hydrogel.

“You can look at dynamics, or how things change in time, in two ways—on the small scale and the big scale,” said MIT professor Gareth McKinley, a co-author of the study. “In our lab at MIT we use mechanical instruments called rheometers to look at changes on the larger scale, and then combined this with XPCS at the APS to understand the dynamics at the microscopic level.”

To get a complete picture of the dynamics of a hydrogel, researchers explored the dynamics of the hydrogel with and without external mechanical stress. This helped reveal the connections between the small-scale and large-scale changes in the material.

“XPCS helped us understand the microscopic rearrangements that occur inside soft gel materials, especially in the presence of mechanical stress. This has implications for designing soft materials ranging from hydrogels used in drug delivery and cell culture, to emulsions and pastes used in consumer products,” said MIT graduate student Jake Song, lead author of the study.

Soft material relaxation at the interfaces

Another study, published in ACS Nano by scientists at Argonne, DOE’s Lawrence Berkeley National Laboratory (Berkeley Lab), and University of Massachusetts (UMASS) Amherst, also utilizes XPCS to learn about soft materials. But in this case, researchers were studying a mixture made of oil and water.

Between the surfaces of the two liquids, researchers place very fine particles known as nanoparticles. At this location, particles were likely to jam, or become more tightly packed, and bind to form solid-like structures. Researchers used XPCS to measure dynamics as jamming was in effect.

“Ultimately what we got from XPCS was a better understanding of how jamming is moderated by the dynamics of the system, which are insights we could use in the future to make liquid structures that behave in a particular way,” said co-author Tom Russell, visiting scientist at Berkeley Lab and professor at UMass Amherst.

Future of X-ray tools at the APS

With the APS currently undergoing a major upgrade, scientists have the potential to get even more out of techniques such as XPCS in the future.

The upgraded APS will drastically increase the X-ray beam coherence, meaning how synchronized the rays’ wavefronts are, and this specific technique will improve by up to a million times as a result.

“These upgrades will greatly expand the types of materials we can measure with this technique in the future,” said Zhang. “It will be exciting to see the new science the APS can enable in years to come.”

More information:

Jake Song et al, Microscopic dynamics underlying the stress relaxation of arrested soft materials, Proceedings of the National Academy of Sciences (2022). DOI: 10.1073/pnas.2201566119

Paul Y. Kim et al, Relaxation and Aging of Nanosphere Assemblies at a Water–Oil Interface, ACS Nano (2022). DOI: 10.1021/acsnano.2c00020

Provided by

Argonne National Laboratory

Citation:

Through thick and thin: X-rays track the behavior of soft materials (2022, October 11)