The Nobel Prize in Chemistry 2014 was awarded for the development of super-resolved fluorescence microscopy. Inspired by this work, scientists at Institute of Photonic Chips (IPC), University of Shanghai for Science and Technology (USST) have developed an innovative laser scribing pathway for the fabrication of ultrafine graphene patterns.

This discovery breaks the diffraction limit barrier for carbon-based optical lithography toward a nano world. Recently their work entitled “Two-beam ultrafast laser scribing of graphene patterns with 90 nm sub-diffraction feature size” was published in the journal Ultrafast Science. The authors are Prof. Xi Chen and Prof. Min Gu.

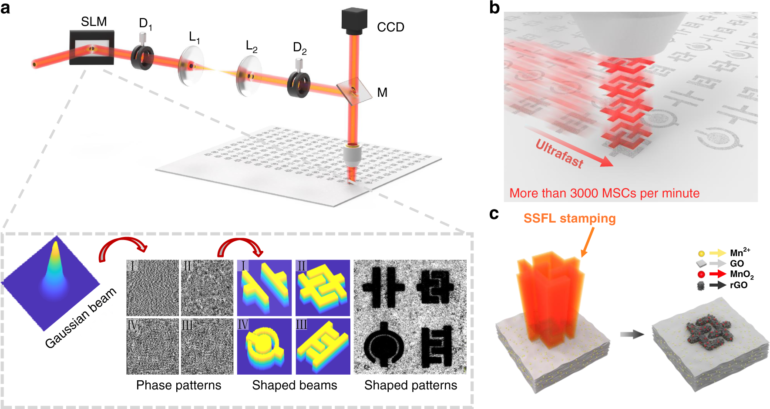

Patterned structures of laser-scribed graphene (LSG) can significantly improve the performance of devices. In the conventional fabrication procedure, a single-beam laser scribing procedure drives the photoreduction of graphene oxide (GO) to form LSG patterns. Owing to the diffraction limit barrier, the line widths of the reported LSG patterns fabricated were microsized, demonstrating a great challenge to achieve features of LSG patterns beyond the diffraction limit barrier.

Recently, based on super-resolved fluorescence microscopy, a two-beam laser scribing technology has been reported. A doughnut-shaped beam inhibits the photoreaction triggered by the writing beam, so resin patterns with linewidths beyond the diffraction limit barriers can be produced.

“Our aim is to fabricate ultrafine graphene patterns through the two-beam pathway,” explains Professor Xi Chen. “However, the inhibition pathway of GO photoreduction has not been realized. The crucial task is to achieve a bottleneck pathway of laser-driven LSG oxidation.”

In the Ultrafast Science paper, a photooxidation pathway of LSG with high reduction degrees has been revealed. A chemical change from LSG to oxidized laser-scribed graphene (OLSG) can be induced under femtosecond laser beam scribing.

Based on the oxidation mechanism, a doughnut-shaped reduction laser beam and a spherical oxidation 532 nm beam are simultaneously controlled for LSG fabrication. The spherical beam turns LSG to OLSG, splitting the LSG line into two sub-diffraction featured segments. A LSG pattern with a minimum LSG linewidth of 90 nm was achieved.

“Graphene is the foundation material for carbon electronics. The two-beam laser scribing procedure offers a powerful strategy for the manufacturing of new-generation micro/nano circuits,” says Professor Min Gu.

More information:

Xi Chen et al, Two-Beam Ultrafast Laser Scribing of Graphene Patterns with 90-nm Subdiffraction Feature Size, Ultrafast Science (2022). DOI: 10.34133/ultrafastscience.0001

Provided by

Ultrafast Science

Citation:

Two-beam ultrafast laser scribing of ultrafine graphene patterns (2023, February 10)