Most people who hear the word ‘glasses’ will probably think of drinking glasses or corrective eyewear. Hardly anyone will think of metals. But metallic glasses, or ‘amorphous metals’ as they are also known, are playing an increasingly important role in both scientific research and technology.

When metal melts are cooled so rapidly that they solidify within a fraction of a second, they remain chaotic and disordered at the atomic level. Had they been cooled slowly, the atoms would have had time to rearrange and to form an ordered crystal lattice structure, but rapid cooling means the atoms in the disordered liquid melt can’t rearrange quickly enough and are essentially frozen in position.

This atomic disorder imparts to these ‘non-equilibrium’ metallic glasses properties that are quite different to those of the ordered crystalline alloy. Metallic glasses can be stronger than steel while having the elasticity of a polymer.

What happens at the atomic level during the ‘glass transition’—the sudden transition from the liquid to the solid glass phase is something that Isabella Gallino has been studying for many years. A few years ago, materials scientist Gallino was able to dispel a widely accepted paradigm in her field.

Conventional wisdom held that when a metallic melt underwent a glass transition, the material would lose its liquid-state properties at the same time that it acquired its solid-state properties. Gallino showed that this is not in fact the case and explained the behavior in terms of the different sizes of atoms involved.

When the large atoms have already frozen and are essentially immobile, the smaller atoms can still move around and can therefore still impart liquid properties to the alloy. It is only when the smaller atoms finally freeze, that the liquid fully vitrifies into a glass.

This fact is crucial in understanding a recent observation made by Dr. Isabella Gallino, her colleague Professor Ralf Busch and several of his doctoral students (all at Saarland University) in collaboration with Daniele Cangialosi from the Materials Physics Center, San Sebastián, Spain as well as colleagues from the U.S..

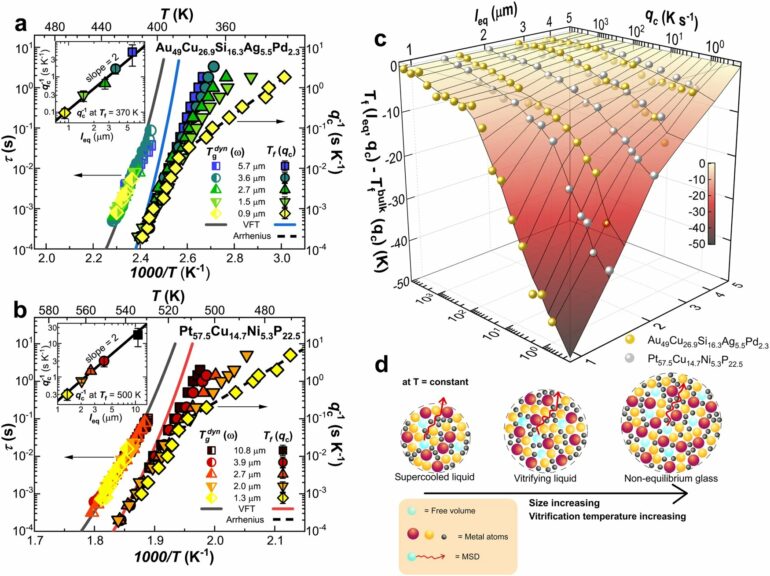

The smaller the metal droplet is in the experiment, the longer it can ‘resist’ being frozen into the glass state. The team showed that this is particularly pronounced for sample dimensions below ten micrometers in size. Put in simple terms, a smaller sample of an alloy requires lower temperatures before it can solidify to form a metallic glass. The temperature at which a 10.8-micrometer droplet freezes to form a metallic glass is around 40 degrees Kelvin higher than the temperature at which a 1.3 micrometer droplet solidifies.

Ralf Busch summarized this finding as follows: “If we start warming the material up from a low temperature, smaller pieces of amorphous alloys will thaw earlier than larger ones.” The material becomes ‘liquid’ again and loses the properties that it had as a solid metallic glass. However, the observed effect decreases sharply at sample sizes above about 10 micrometers.

Above this threshold, there is no dimension-dependent difference in the way that glass-forming materials behave. The freezing and thawing processes in the glass transition zone were measured with an instrument known as a Flash DSC chip calorimeter that allows small sample quantities to be studied under conditions of very rapid cooling and heating.

“The effect we have observed is universal,” said Isabella Gallino, commenting on the far-reaching implications of her discovery. This phenomenon applies not only to metallic alloys but to all other materials that solidify into a glass rather than undergoing crystallization. And there are a large number of substances known, which in their condensed state form an amorphous rather than an ordered crystalline structure.

Even water, which in its frozen state has a regular crystal structure here on Earth, is glassy or amorphous in the wider universe, such as the water found in comets at temperatures below -150°С. From a scientific perspective, the process of vitrification—the glass transition from the liquid state to the amorphous solid state—is of fundamental interest.

That’s why the observations made by Isabella Gallino, Ralf Busch and their international colleagues are of considerable interest in many fields such as the semiconductor industry or the composite materials sector. Many of the materials in these industries are interconnected at the micrometer level.

Thanks to the work of Gallino, Busch and others, we now know that materials on this scale will become ‘disordered’ more quickly and thus lose their properties the smaller they are. Materials scientists will therefore be able to use this information in future to specifically influence the durability of materials.

The findings are published in the journal Nature Communications.

More information:

Valerio Di Lisio et al, Size-dependent vitrification in metallic glasses, Nature Communications (2023). DOI: 10.1038/s41467-023-40417-4

Provided by

Saarland University

Citation:

Why tiny metal droplets take longer to solidify into glass: Fundamental observation in materials science (2023, August 14)