Scientists at the U.S. Department of Energy’s (DOE) Brookhaven National Laboratory have designed and tested the world’s highest voltage polarized electron gun, a key piece of technology needed for building the world’s first fully polarized Electron-Ion Collider (EIC).

The work is published in the journal Applied Physics Letters.

The EIC, a state-of-the-art nuclear physics facility being built at Brookhaven in partnership with DOE’s Thomas Jefferson National Accelerator Facility (Jefferson Lab), will accelerate and collide polarized electrons with polarized protons and ions—atoms stripped of their electrons—so scientists can investigate the innermost building blocks of visible matter.

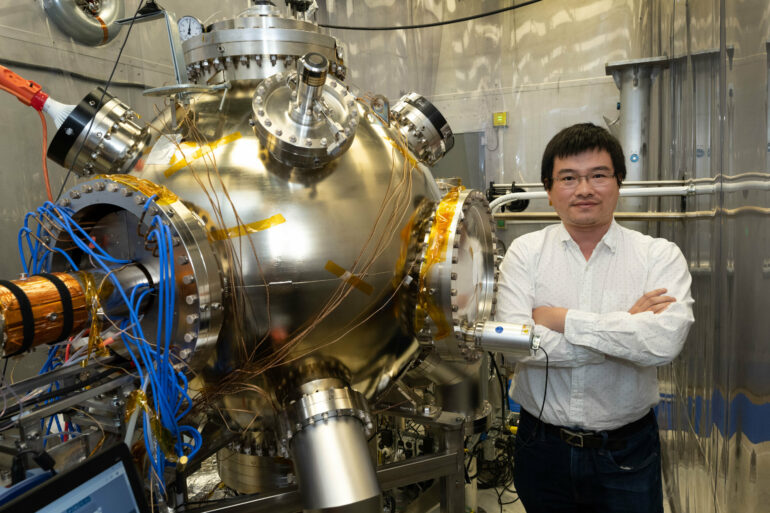

“This gun not only exceeds the EIC requirements, but we also get world-leading results,” said Brookhaven Lab physicist Erdong Wang, the chief architect and implementor of the device.

Wang proposed the electron gun as a research and development project back in 2017 and has been spearheading its design, engineering, assembly, and testing ever since. Much of the work and all the testing were done at Stony Brook University (SBU), a partner in Brookhaven Science Associates, the entity that manages Brookhaven Lab on behalf of DOE.

The project drew on the expertise of scientific and technical staff and graduate students there and at several EIC collaborating institutions, including Jefferson Lab, Old Dominion University, and others.

“Our team includes experts in beam dynamics, high voltage, materials science, lasers, engineering, and beam diagnostics,” Wang said.

EIC Science Director Abhay Deshpande, a professor of physics at SBU who is also serving as Brookhaven Lab’s interim associate laboratory director for Nuclear and Particle Physics, said, “This project is a great example of the strong collaboration between Brookhaven Lab and Stony Brook, particularly for research in nuclear physics and the development of technologies needed for the EIC.”

Key beam characteristics

Though nothing like the type of gun that signals the start of a race, this direct-current, laser-driven polarized electron gun will serve as a starting gun of sorts for one of the EIC’s streams of colliding particles. It will produce and fire off the electrons that make their way into and around the 2.4-mile-circumference circular collider.

“We put the ‘e’ in the EIC,” said John Skaritka, the Brookhaven Lab mechanical engineer who led the mechanical design and planning for the project.

Cars that boast acceleration rates of “zero to 60” in mere seconds have nothing on this gun’s power. “We speed up the velocity of electrons to 80% the speed of light,” Wang said. That’s an acceleration of zero to more than 500 million miles per hour—over the span of just two inches inside the gun in about two ten-billionths of a second.

But speed isn’t the only crucial characteristic of the EIC’s electrons as they come out of the starting gate. In fact, they’ll be brought much closer to the speed of light in subsequent stages of acceleration. The true success of the electron gun is in delivering electron beam characteristics that are essential to these particles’ ability to peer inside the protons and atomic nuclei with which they will collide at the EIC.

Among the most important requirements: producing beams of electrons in short, tightly packed bunches where the particles’ “spins” are mostly pointing in the same direction.

According to Wang, short, intermittent bunches of electrons can be easily accelerated to high energy by radiofrequency cavities. These cavities produce electric fields that give intermittent acceleration “kicks” to charged particles, pushing them faster and faster.

Once the electrons are up to speed and ready for collisions, Wang said, “having many, many electrons in a single bunch gives you very high densities, so you have a high probability that they will collide with protons or ions in the beam traveling around the EIC in the opposite direction.”

The polarization, or alignment of the particles’ spins, is extremely important to the EIC’s physics research goals. The collider is being built, in part, to explore the origins of spin, an intrinsic particle property that is somewhat analogous to the spin of a toy top on its axis.

Spin is responsible for the structure and order of all visible matter—governing, for example, the magnetic properties of protons that make magnetic resonance imaging (MRI) possible. But how proton spin is generated is still a mystery.

The EIC will be the world’s first collider where the spins of both the electron and ion beams can be controlled and aligned. By colliding spin-polarized electrons with polarized protons, EIC scientists will tease apart how the proton’s spin arises from the spins and motion of its internal building blocks, quarks and gluons.

EIC scientists will also use spin to establish a frame of reference for mapping out the distribution of quarks and gluons within protons and nuclei, allowing them to create detailed 3D images of the proton’s internal structure. These studies will help scientists gain a deeper understanding of quark-gluon interactions governed by the strongest, least-understood force of nature.

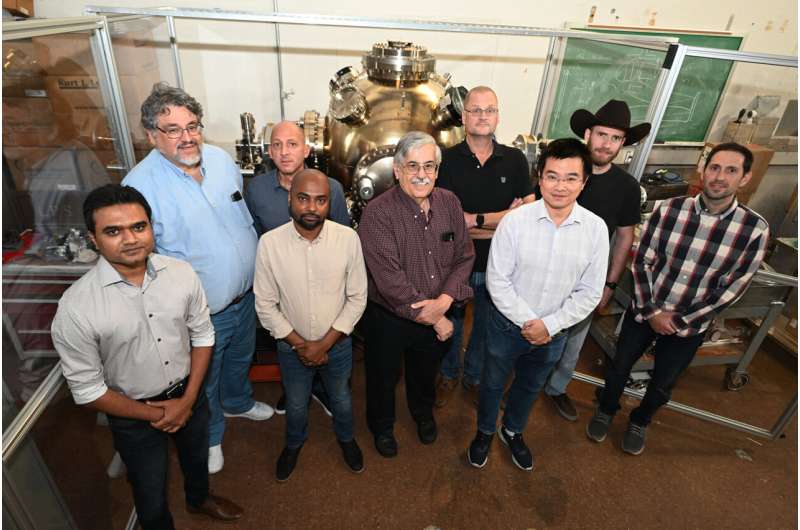

Part of the team that designed and tested the high-voltage polarized electron gun, left to right: Jyoti Biswas, accelerator physicist, Electron-Ion Collider (EIC); John Skaritka, mechanical engineer, Collider-Accelerator Department (C-AD); Ronald Napoli, Technician, C-AD; Omer Rahman, accelerator physicist, C-AD; Bob Lambiase, electrical engineer, C-AD; Christopher Degen, software engineer, C-AD; Erdong Wang, accelerator physicist, EIC, Patrick Inacker-Mix, laser engineer, C-AD; Matthew Paniccia, electrical engineer, C-AD. © Kevin Coughlin/Brookhaven National Laboratory

“For the EIC, we need polarized electron bunches with spins oriented forward and backward simultaneously, so we need to generate a highly polarized electron beam from the source,” Wang said.

Maxing out photoelectric efficiency

The science behind generating these electron beams dates back to the discovery of the photoelectric effect, where a series of experiments in the late 1800s and early 1900s showed that light with sufficient energy could knock electrons free from a metal. Albert Einstein’s explanation for why this happens earned him the 1921 Nobel Prize in Physics.

Technologies that harness this photoelectric phenomenon and materials that emit electrons with higher efficiency have advanced substantially over the past 100 years. Still, no existing electron gun could produce the high-voltage, high-intensity polarized beams the EIC requires.

So, Wang and a team of colleagues from Brookhaven’s Collider-Accelerator Department, the EIC Directorate, SBU, and other collaborating institutions developed a unique photocathode structure and innovative approaches to achieve a superior performance.

“SBU students were involved in the foundational research from the beginning of the project,” Wang said. “We learned a lot based on the last several decades of effort, but we pushed the development of novel concepts to produce a truly unique gun.”

Nanostructured photocathode

Collaborators from Old Dominion University and Jefferson Lab in Virginia developed a new approach for making the gun’s photocathode—the material that generates the photoelectric electrons. This material is a thin crystal of gallium arsenide, but the team tweaked the recipe and arranged the material in layers to give it a periodic structure.

“It’s a very complex structure, a 100-nanometer layered superlattice wafer on top of a bulk material that’s just 0.4 millimeters thick,” Wang noted.

When a laser with certain properties strikes the layers, only electrons with their spins aligned a particular way get ejected from the material. The result: highly polarized beams.

The team also added a reflecting layer to enhance the laser light’s interaction with the material and a surface coating that essentially repels electrons to help push them away as they skip from the cathode.

While the material has a very high “quantum efficiency,” meaning it’s good at emitting electrons when struck by light, “the energy of these emitted electrons is extremely low,” Wang said. “Without applying voltage, the electrons would just stay at the surface of the material; they wouldn’t move,” he said.

So, the scientists mount the gallium arsenide photocathode opposite an anode and apply a very high voltage to get things moving.

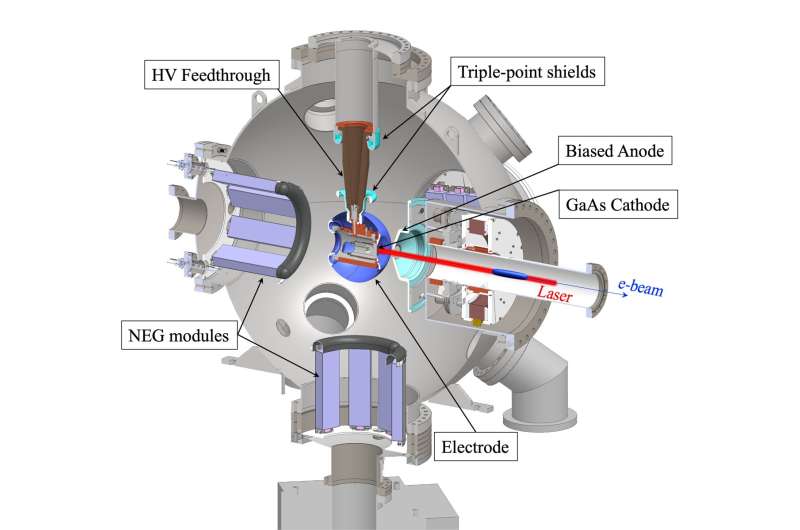

“First, we apply the voltage to the cathode. Then, when we shine a laser on the gallium arsenide wafer, the electron beam comes out toward the anode. The electron energy goes from zero to 320 kiloelectron volts over the space of the gap—about two inches,” Wang said.

Laser-driven action

The light the scientists use to kick the electrons free comes from a laser. Lasers, where all the light waves are in sync and lined up in a very concentrated narrow beam, can generate very high-quality electron beams. The scientists figured out how to tune the laser wavelength to maximize the electron polarization and the photocathode’s quantum efficiency.

“We discovered a small wavelength zone that can get both high polarization and long cathode lifetime,” Wang said.

Lasers can also be generated in very fast pulses. That fast pulsing is perfect for producing short, intermittent, bunches of electrons amenable to acceleration, Wang said. The combination of pulsing with the high voltage of the gun ensures that each bunch contains a high “bunch charge”—meaning nearly 70 billion electrons per bunch.

In addition, the team uses a polarized laser where the “wave vectors” rotate around a circle, either clockwise or counterclockwise. “The direction of laser polarization determines the polarization of the emitted electrons,” Wang said.

“By rapidly switching the laser from clockwise to counterclockwise polarization, we can switch the spin direction of the electrons very fast.” That means scientists can compare collisions with electron spins pointing forward vs. backward during the same set of events while everything else remains the same.

Delivering the high voltage—in a vacuum

One of the trickiest parts of using gallium arsenide photocathodes is that the material can be very easily damaged by residual gas.

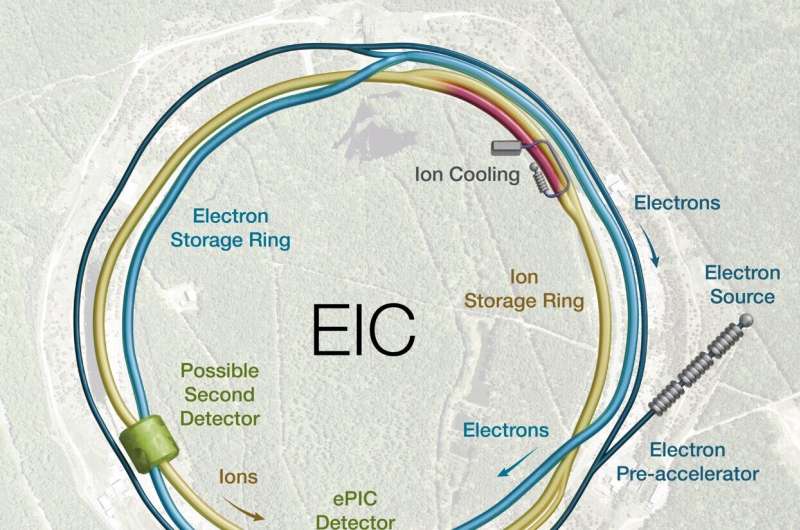

EIC schematic: This graphic shows the location of the photocathode electron gun (Electron Source) that will produce the electron beam that enters the electron accelerator and storage rings for collisions with protons or ions traveling in the opposite direction. © Valerie Lentz/Brookhaven National Laboratory

Jyoti Biswas, now an EIC staff physicist, investigated the gallium arsenide photocathode damage mechanism and systematically evaluated various activation methods as part of his Ph.D. thesis. He also studied the residual gas distributions inside the gun.

“These pioneering studies played a key role in guiding the gun design and commissioning,” said Wang, who served as Biswas’ graduate studies supervisor in the Brookhaven/SBU Center for Accelerator Science and Education.

To protect the precious photocathode material, the team placed the entire photocathode-anode-laser system within an extremely high vacuum environment. “It’s even more of a vacuum than on the moon,” Wang said.

But extremely high-vacuum systems are difficult to achieve on Earth, even with many expensive pumps. And while the vacuum makes it easier to maintain the high voltage necessary for generating high-intensity electron beams, it complicates the delivery of power to the gun.

“One challenge is how to get the high voltage to the cathode inside a vacuum,” said Bob Lambiase, the lead electrical engineer on the project. “The high voltage has to be insulated from the gun and any conductive materials to prevent electrical arcs that could damage the whole system.”

Many photocathode guns have their voltage delivered from a power supply to a connector outside the main gun chamber, with the whole gun system being housed in a vessel filled with an insulating gas. The gas is needed to keep the connecting cable from transferring voltage to any of the gun’s metal components. But that insulating gas, sulfur hexafluoride, is a powerful atmospheric heat trapper.

Wang, Lambiase, and Skaritka, a specialist in vacuum systems—along with their collaborators—figured out how to do away with the surrounding greenhouse-gas-filled chamber. Instead of connecting the power outside the gun and insulating the whole system, their setup plugs a high-voltage cord into a specialized connector inside the gun.

Lambiase, the electrical expert, developed the design. “Our connector is derived from the type used on standard X-ray machines, but we jazzed it up a bit to increase its capability and performance.”

The cone-shaped connector gets plugged into a ceramic cone inside the gun, with the gap between the “plug” and “socket” filled with silicone grease and a “high dielectric strength” fluid—a substance that can withstand high voltages without breaking down. This fluid fills all possible voids to keep voltage from “leaking” out of the connection to the metal components of the gun.

The fluid also cools the cathode, which is located at the tip of the cone, to protect it from damage from both the laser and high voltage.

The cable that carries the voltage from the power supply also has a modified design. It’s covered with a semiconductor coating, developed with industrial partners, to keep potentially dangerous charges from building up.

“This semiconductor coating is absolutely unique,” Skaritka said. “It has just enough conduction to drain off the charge and absorb energy that could otherwise damage the gun.”

Polarized electron gun: The cone-shaped high-voltage (HV) feedthrough connector delivers current to gun. When laser photons strike the gallium-arsenide (GaAs) photocathode, emitted electrons flow from cathode to anode and out of the gun as a highly polarized electron beam (e-beam). © Erdong Wang/Brookhaven National Laboratory

With the modified cable, the team was able to run a long enough cord to locate the power supply in a separate room, eliminating the need for surrounding the power supply with insulating sulfur hexafluoride.

“We are the first to develop a system where both the gun and power supply are free of this greenhouse gas,” Wang said. The gas-free setup is also safer, he noted, because there’s no danger of leaking gas causing oxygen deficiencies in the area.

Making it shine

The team had other mundane challenges to face. For example, hydrogen gas that gets trapped within stainless steel during manufacturing could seep from the gun’s metal components into the vacuum and mess up the precision electron beams.

To deal with this, the Brookhaven team used a procedure for baking out trapped gases prior to gun assembly. They started by placing the stainless-steel components in an oven fired up to more than 1,650 degrees Fahrenheit (900 degrees Celsius). “That releases all hydrogen trapped within the surface of the stainless steel and reduces the permeability of the material,” Wang said.

Then, they used a procedure developed by colleagues at Jefferson Lab to polish all the stainless-steel components to a high mirror polish. The smooth finish is another enhancement essential for establishing and maintaining the high-voltage difference between the cathode and anode.

This polishing process uses “a tumbling machine like those people use to polish gemstones,” Wang noted, “but we needed a very soft polish.” Material derived from crushed corn cobs, followed by high-pressure rinsing learned from superconducting radiofrequency cavity experts, provided the perfect finish.

Once the components cooled, the team assembled the gun—all but the photocathode wafer. Then, they pumped out the air and put the completed gun back into an oven for a weeklong bake at a balmy 660 degrees Fahrenheit (350 Celsius) to remove any remaining surface contaminants.

Finally, they connected another vacuum chamber containing the photocathode. “Using a precision cathode alignment assembly developed by Skarita with assistance from another SBU graduate student, the team set this crucial component in place.”

Then it was off to the electron races.

In commissioning tests in a basement lab at SBU, ramping up the voltage to the goal of 350 kilovolts took about 23 hours. Then the gun operated maintenance free for six months. Quality tests showed the electrons have all the characteristics needed for the EIC’s proton- and ion-probing electron beams.

“Over the last two years of operation, the high voltage is always very stable. This is the highest-voltage and highest-intensity polarized electron gun in the world,” Wang said.

Wang and other members of the team are now focused on developing components for the electrons’ next stage of acceleration, as well as an even higher-voltage and very-high-average-current gun that will produce another stream of electrons for cooling the ion beams at the EIC.

More information:

Erdong Wang et al, High-intensity polarized electron gun featuring distributed Bragg reflector GaAs photocathode, Applied Physics Letters (2024). DOI: 10.1063/5.0216694

Provided by

Brookhaven National Laboratory

Citation:

World’s highest-voltage gun accelerates electrons from zero to 80% the speed of light (2024, October 10)