Most space mission systems historically have used one spacecraft designed to complete an entire mission independently. Whether it was a weather satellite or a human-crewed module like Apollo, nearly every spacecraft was deployed and performed its one-off mission completely on its own.

But today, space industry organizations are exploring missions with many satellites working together. For example, SpaceX’s Starlink constellations include thousands of satellites. And new spacecraft could soon have the capabilities to link up or engage with other satellites in orbit for repairs or refueling.

Some of these spacecraft are already operating and serving customers, such as Northrop Grumman’s mission extension vehicle. This orbiting craft has extended the lives of multiple communications satellites.

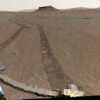

Northrup Grumman’s mission extension vehicle is one example of a craft designed to service other satellites and spacecraft while in orbit.

These new design options and in-orbit capabilities make space missions look more like large logistics operations on Earth.

We’re researchers who have studied the space industry for years. We’ve studied how the space sector could learn lessons from companies like Amazon or FedEx about managing complex fleets and coordinating operations.

Lessons from the ground transportation network

Space mission designers plan their routes in order to deliver their payloads to the Moon or Mars, or orbit efficiently within a set of cost, timeline and capacity constraints. But when they need to coordinate multiple space vehicles working together, route planning can get complicated.

Logistics companies on the ground solve similar problems every day and transport goods and commodities across the globe. So, researchers can study how these companies manage their logistics to help space companies and agencies figure out how to successfully plan their mission operations.

One NASA-funded study in the early 2000s had an idea for simulating space logistics operations. These researchers viewed orbits or planets as cities and the trajectories connecting them as routes. They also viewed the payload, consumables, fuel and other items to transport as commodities.

This approach helped them reframe the space mission problem as a commodity flow problem – a type of question that ground logistics companies work on all the time.

Lessons from ground logistics infrastructure

New capabilities for refueling and repairing spacecraft in orbit create new opportunities as well as challenges.

Namely, space operators don’t usually know which satellite will be the next one to fail or when that will happen. For these new technologies to be useful, space mission designers would need to come up with an infrastructure system. That could look like a fleet of service vehicles and depots in space that quickly respond to any unpredictable events.

Fortunately, space…