Utilizing soft, flexible materials such as cloth, paper, and silicone, soft robotic grippers act like a robot’s hand to perform functions such as safely grasping and releasing objects. Unlike conventional rigid material grippers, they are more flexible and safe, and are being researched for household robots that handle fragile objects such as eggs, or for logistics robots that need to carry various types of objects. However, its low load capacity makes it difficult to lift heavy objects, and its poor grasping stability makes it easy to lose the object even under mild external impact.

Dr. Song, Kahye of the Intelligent Robotics Research Center at the Korea Advanced Institute of Science and Technology (KIST), along with Professor Lee, Dae-Young of the Department of Aerospace Engineering at the Korea Advanced Institute of Science and Technology (KAIST), have jointly developed a soft gripper with a woven structure that can grip objects weighing more than 100 kg with 130 grams of material.

The results of the study were published on August 2 in Nature Communications .

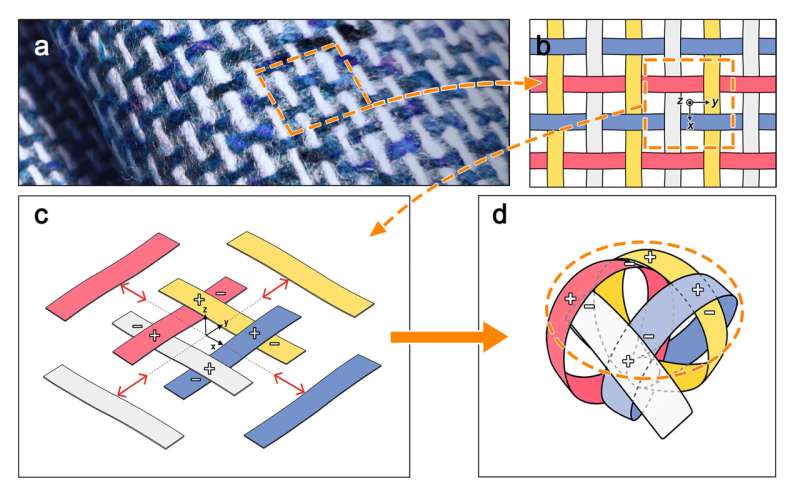

To increase the loading capacity of the soft robot gripper, the research team applied a new structure inspired by textiles, as opposed to the conventional method of developing new materials or reinforcing the structure.

The weaving technique they focused on involves tightly intertwining individual threads to create a strong fabric, which can reliably support heavy objects and has been used for centuries in clothing, bags, and industrial textiles. The team used thin PET plastic. The grippers were designed to allow the strips to intertwine and unwind into a woven structure.

Gripper schematic with weave structure. © Korea Institute of Science and Technology

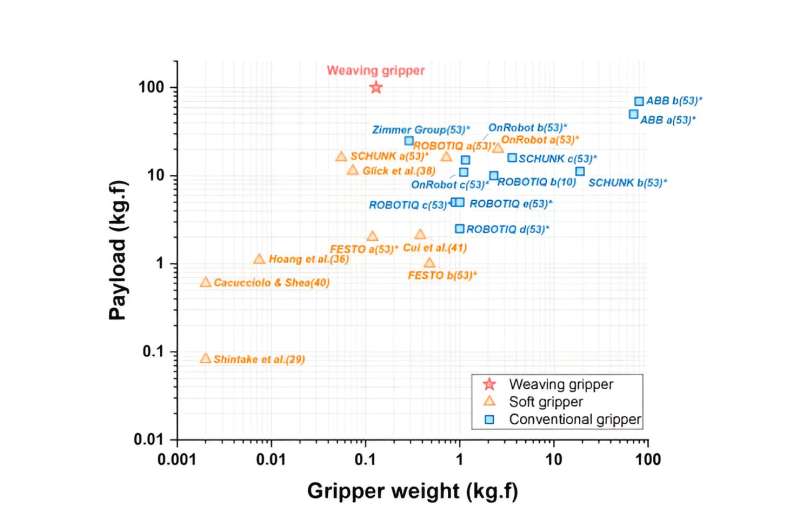

The resulting woven gripper weighs 130 grams and can grip an object weighing 100 kilograms. Conventional grippers of the same weight can lift no more than 20 kilograms at most, and considering that a gripper that can lift the same weight weighs 100 kilograms, the team succeeded in increasing the load capacity relative to its own weight.

Also, the soft robot gripper developed by the research team uses plastic, which costs only a few thousand won (approx. $2) per unit of material, and can be used as a universal gripper that can grip objects of various shapes and weights, making it highly competitive in price. In addition, since the soft robot gripper can be manufactured by simply fastening a plastic strip, the manufacturing process can be completed in less than 10 minutes, and it is easy to replace and maintain, so the process efficiency is excellent.

In addition to PET, which is the main material used by the research team, the gripper can also be made of various materials such as rubber and compounds that possess elasticity, allowing the team to customize and utilize grippers suitable for industrial and logistics sites that require strong gripping performance or various environments that need to withstand extreme conditions.

Comparison of gripper weight to payload (maximum weight the robot can lift) for the woven gripper, soft gripper, and rigid gripper. © Korea Institute of Science and Technology

“The woven structure gripper developed by KIST and KAIST has the strengths of a soft robot but can grasp heavy objects at the level of a rigid gripper,” said Dr. Song. “It can be manufactured in a variety of sizes, from coins to cars, and can grip objects of various shapes and weights, from thin cards to flowers, so it is expected to be used in fields such as industry, logistics, and housework that require soft grippers.”

More information:

Gyeongji Kang et al, Grasping through dynamic weaving with entangled closed loops, Nature Communications (2023). DOI: 10.1038/s41467-023-40358-y

Provided by

Korea Institute of Science and Technology

Citation:

A 130g soft robot gripper that can lift 100kg (2023, October 6)