Electrifying transportation is an essential step towards mitigating climate change. To improve the power, efficiency and safety of electric vehicles, researchers must continue to develop better batteries.

All-solid-state lithium batteries (SSBs), which have a solid electrolyte instead of a liquid, are safer than traditional lithium-ion batteries because they are less flammable and more stable at higher temperatures. They could also have higher energy densities than lithium-ion batteries, allowing for longer lasting batteries in smaller sizes for portable electronics and other applications.

A research team led by Joshua Gallaway of Northeastern University in Boston and scientists at the Department of Energy’s (DOE) Argonne National Laboratory recently tested how the composition of thick cathodes affected electrochemical reactions in SSBs. The team used the resources of the Advanced Photon Source (APS), a DOE Office of Science user facility at Argonne. Their discoveries were published in the journal ACS Energy Letters.

Gallaway relates batteries to sandwiches—they are comprised of an anode on one side, a cathode on the other, a separator in the middle, and electrolyte solution throughout. When batteries provide power, lithium ions flow from the anode to cathode through the electrolyte. While SSBs don’t require traditional separators because the electrolyte separates the anode and cathode, they do require thick cathodes.

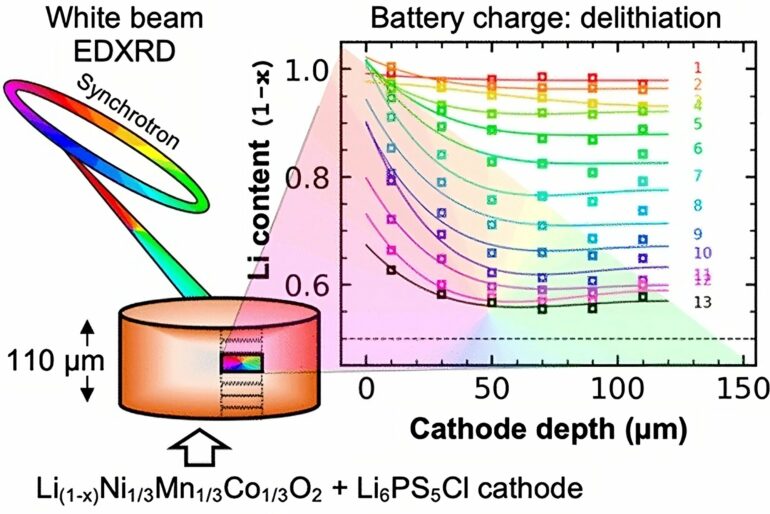

In this study, Gallaway and his colleagues evaluated batteries with thick cathodes that were comprised of two materials: a sulfide solid electrolyte called LPSC and an NMC (nickel, manganese, cobalt) cathode active material (CAM). They altered the composition of these two materials, so some batteries were 80% CAM, 20% LPSC, while others were 70% CAM, 30% LPSC and 40% CAM, 60% LPSC. Then, they used X-ray imaging and scattering at APS beamline 6-BM-A to measure six slices within the cathode and solid-state electrolyte.

“If you divide the cathode into slices, you want all the slices to act the same,” Gallaway said. Changing the composition or thickness of the cathode can change where the electrochemical reactions occur.

Gallaway teamed up with John Okasinski, a physicist at the APS, to characterize electrochemical reactions in the batteries.

“When people study batteries, they often measure power at the two terminals. But there’s a bunch of complicated structures in between that dictate how well the battery performs,” said Okasinski. By using X-ray beams that penetrated into the battery materials, the researchers were able to non-destructively study performance in each region of the battery.

They found that cathode composition had a huge impact on how electrochemical reactions take place. For example, in an SSB with an 80% CAM cathode, the cathode slice nearest the anode reacted first and the farthest slice reacted last. But in an SSB with a 70% CAM cathode, the farthest slice reacted first and the nearest slice reacted last.

“The reaction is highly non-uniform—and we don’t really see a situation where it is uniform,” Gallaway said. He also noted that this could lead to faster degradation of the battery material.

Uncovering how reactions take place within batteries is an important step towards designing better batteries for electric vehicles, portable electronics and other applications, Gallaway said. “How all-solid-state batteries are designed will determine what their applications will be and how they will be optimized moving forward.”

More information:

Alyssa M. Stavola et al, Lithiation Gradients and Tortuosity Factors in Thick NMC111-Argyrodite Solid-State Cathodes, ACS Energy Letters (2023). DOI: 10.1021/acsenergylett.2c02699

Provided by

Argonne National Laboratory

Citation:

A first step to designing better solid-state batteries (2023, May 23)