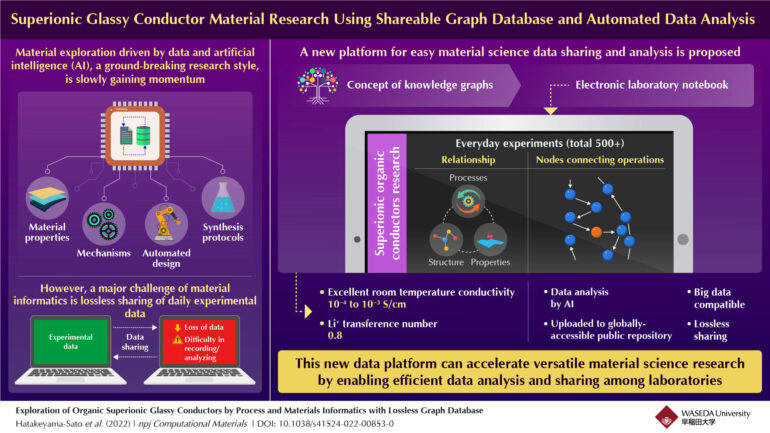

In the field of materials science, even small variations in experimental parameters and protocols can lead to unwanted changes in the properties of a material. A ground-breaking development in this field came with the advent of materials informatics—a heavily data-reliant field, which focuses on materials data, including synthesis protocols, properties, mechanisms, and structures. It has benefitted significantly from artificial intelligence (AI), which enables large-scale, automated data-analyses, material design, and experiments which can aid the discovery of useful materials.

Unfortunately, back-and-forth data sharing within the scientific community often results in data loss. This is because most material databases and research papers largely focus on structure-property relations and less on important information such as essential experimental protocols.

To address these issues, a team of researchers led by Assistant Professor Kan Hatakeyama-Sato and Professor Kenichi Oyaizu from Waseda University in Japan developed a laboratory data management platform that describes the relations between properties, structures, and experimental processes in electronic laboratory notebooks. In this electronic laboratory notebook, experimental events and related environmental parameters are represented as knowledge graphs.

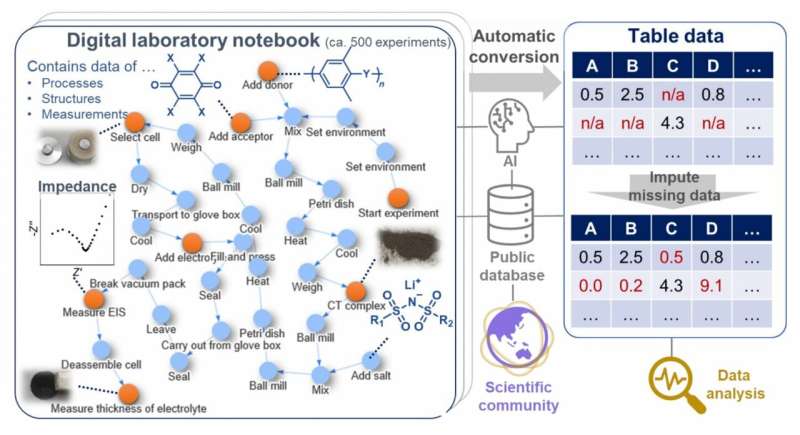

Their study, which was published in npj Computational Materials on August 17, 2022, relied on the concept that experimental information can be described without loss as knowledge graphs. The team incorporated an AI-based algorithm that could automatically convert these knowledge graphs into tables and upload them into a public repository. This step was incorporated to ensure that data sharing was lossless, and to enable the scientific community to gain better insights into the experimental conditions.

To demonstrate the applicability of this platform, the team used it to explore superionic conductivity in organic lithium (Li+)-ion electrolytes. They recorded everyday raw data from over 500 experiments—both successful and unsuccessful ones—into the electronic laboratory notebook. Next, the data conversion module automatically transformed the knowledge graph data into machine-learnable datasets and analyzed the relationship between experimental operations and results. This analysis revealed the important parameters needed to achieve excellent room temperature ionic conductivity of 10−4–10−3 S/cm and a Li+ transference number as high as 0.8.

The new data platform allows efficient recording and storage of everyday experimental events as graphs and then converts them into data tables which facilitates further AI-based analysis. © Kan Hatakeyama-Sato from Waseda University

So, what are the real-time applications of this platform? Hatakeyama-Sato says, “This platform is currently applicable to solid-state batteries and with improved performance will be able to contribute to the development of safer and high-capacity batteries.”

This study not only provides a platform for reliable data-oriented research but ensures that all information, including experimental results and raw measurement data, is available to everyone publicly.

Discussing its long-term implications, Hatakeyama-Sato says, “By sharing raw experimental data among researchers across the globe, novel functional materials could be discovered more quickly. This approach can also accelerate the development of energy-related devices, including next-generation batteries and solar cells.”

More information:

Kan Hatakeyama-Sato et al, Exploration of organic superionic glassy conductors by process and materials informatics with lossless graph database, npj Computational Materials (2022). DOI: 10.1038/s41524-022-00853-0

Citation:

A lossless data management platform for machine learning and sharing of experimental information (2022, September 22)