Lithium-air batteries, sometimes known as lithium-oxygen batteries (Li-O2), comprise a lithium metal anode, an organic electrolyte and a porous carbon cathode. During discharge, oxygen in the surrounding air reacts with lithium at the cathode, releasing energy in the process. Given their extremely high energy density (> 3500 Wh kg-1), Li-O2 batteries could potentially lead the way in generating greener sources for energy security.

Yet advances in the technology have stalled because specially designed carbon cathodes lack certain characteristics. Namely, abundant active sites where chemical reactions can take place, and space large enough to accommodate the nucleation and growth of discharge products, which is needed to achieve a high energy density.

Researchers from Tohoku University and their partners have developed a special type of porous carbon sheet called a graphene mesosponge sheet (GMS-sheet). The design, which was reported in the journal Advanced Energy Materials, significantly improves the energy density and cycle stability in Li-O2 batteries, setting a high-performance standard.

“The rational design of the porous structure for the carbon cathode is crucial for achieving a high-performance, but it is also a major challenge,” says Hirotomo Nishihara, professor at Tohoku University’s Advanced Institute for Materials Research (WPI-AIMR) and co-corresponding author of the paper. “We creatively developed an angstrom-to-millimeter controllable synthesis of free-standing cathodes with minimally stacked graphene free from edge sites.”

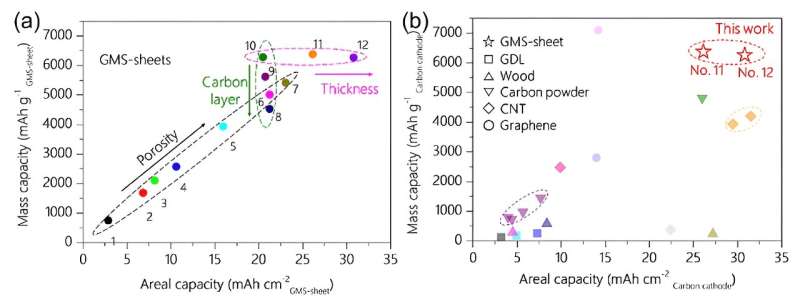

Capacities of Li-O2 batteries with GMS-sheets synthesized by different parameters. © Wei Yu, Hirotomo Nishihara et al

To do this, Nishihara and his colleagues rationally controlled three synthesis parameters during a Chemical Vapor Deposition (CVD) process: the pelletization force, the amount of Al2O3 template, and the CVD’s duration. Doing so resulted in a series of GMS-sheets with different porosity, amounts of carbon layers, and sheet thickness.

“It is interesting to see that the specific mass/areal capacities of Li-O2 batteries using GMS-sheets cathodes can be controlled by these three synthesis parameters,” says Wei Yu, assistant professor at Tohoku University’s WPI-AIMR and co-corresponding author of the paper.

“By optimizing these parameters, we’re excited to achieve impressive energy storage capacities, surpassing the performance of the best carbon cathodes, with more than 6,300 milliampere-hours per gram and more than 30.0 milliampere-hours per square centimeter when normalized to the mass and area of GMS-sheets, respectively.”

“With the help of our collaborators from the National Institute for Materials Science, Ochanomizu University, Hokkaido University, Osaka University, and 3DC Inc., we characterized the discharge-charge mechanism using comprehensive in situ techniques and unlocked the key to superior battery performance: the hierarchical porous structure of GMS-sheet,” adds Yu.

Professor Nishihara and his teams believe the GMS-sheet will be a milestone carbon cathode for Li-O2 batteries. “We will continue to promote the practical use of Li-O2 batteries based on our GMS-sheet, and our landscape also covers other metal-gas batteries such as Na-O2, Li-CO2, and Zn-O2 batteries, for which a high-performance carbon cathode is also needed,” concludes Nishihara.

More information:

Wei Yu et al, Hierarchically Porous and Minimally Stacked Graphene Cathodes for High‐Performance Lithium–Oxygen Batteries, Advanced Energy Materials (2023). DOI: 10.1002/aenm.202303055

Citation:

A new benchmark for high-performance carbon cathodes in lithium-oxygen batteries (2023, November 14)