A research team has developed a machine learning-based design of experiments (DOE) method that efficiently optimizes the performance and process conditions of organic thermoelectric devices.

Organic thermoelectric devices convert low-temperature, wasted heat energy from human skin or electronics into electricity. The design of experiments developed in this study, which is the first example of using machine learning in the field of organic thermoelectric devices, is considered a new approach to effectively optimize the performance of organic thermoelectric devices, which have been challenging to optimize due to the presence of many variables.

The research, led by Jeehyun Jeong and Suyeon Park, Ph.D. candidates at Seoul National University’s Department of Electrical and Computer Engineering, was published on Nov. 26 in Advanced Energy Materials.

Organic thermoelectric devices have been attracting attention as energy harvesting devices for next-generation wearable devices and temperature sensors due to their mechanical flexibility and the ability to be fabricated on large surfaces and mass-produced. However, unlike conventional thermoelectric technology, which uses crystalline inorganic materials to interconvert heat and electricity, organic thermoelectric devices using doped semicrystalline polymer thin films have had difficulty in finding optimal performance conditions.

This is because doped semi-crystalline polymer thin films have a complex interaction between process variables (doping concentration, film formation method, annealing temperature, etc.) and thermoelectric performance (electrical conductivity, Seebeck coefficient, etc.). Therefore, it takes significant time and effort to find the conditions that optimize the performance of organic thermoelectric devices through repeated experiments and trial and error.

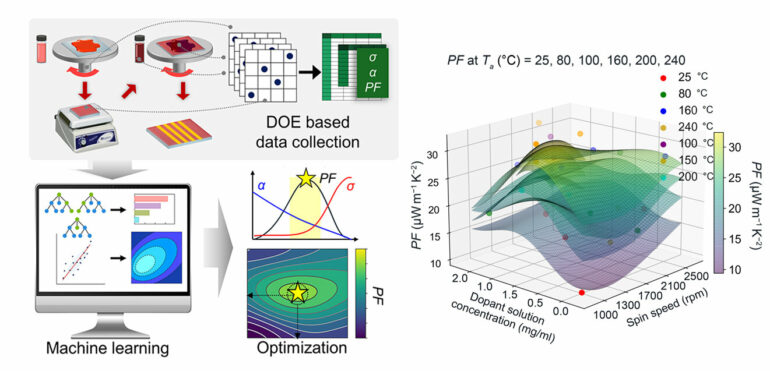

To solve this inefficiency, Kwak and his team introduced a machine learning-based experimental design.

First, the team selected four process variables (spin speed, doping solution concentration, doping time, and annealing temperature) that affect the performance of organic thermoelectric devices, and then set four levels for each variable.

In this case, it is traditional to fabricate a minimum of 256 thermoelectric devices, as the number of possible combinations of the process conditions is calculated by multiplying four levels for each of the four variables (4 x 4 x 4 x 4), in order to evaluate all variables.

However, the team developed an AI-based experimental design that allowed them to identify the importance of key process variables affecting organic thermoelectric device performance and obtain optimal process conditions with only 16 (4×4) thermoelectric devices.

This machine learning-based experimental design method, which can successfully predict the peak performance of organic thermoelectric devices while minimizing repeated experiments, is expected to contribute significantly to the improvement of device performance in the future, as well as provide a direction for the development of materials and processes.

It is also expected that these high-performance organic thermoelectric devices will be widely utilized as power sources for wearable devices and small electronic devices.

“This study is a successful example of AI utilization in that it efficiently derived the optimal thermoelectric performance with only a small number of experiments through machine learning-based technology,” said Jeehyun Jeong, the first author of the paper.

“In particular, it is significant because it proves that the traditional iterative experimental method can be transformed into a data-driven scientific design.”

Professor Jeonghun Kwak, who led the research, added, “The AI-based experimental planning method not only greatly reduced research time and costs, but also enabled us to more systematically understand the interactions between multidimensional variables that were previously difficult to explore.”

Currently leading the Advanced Opto & Nano Electronics Laboratory at Seoul National University, Kwak plans to continue his research on the development of organic thermoelectric devices, as well as the fabrication process and performance optimization of various electronic devices using organic semiconductors.

Researcher Jeehyun Jeong is continuing her research with the goal of further improving the performance of organic thermoelectric devices, and will continue to work on optimizing the process and device design needed for the development of clean energy technologies that utilize waste heat.

More information:

Jeehyun Jeong et al, Machine‐Learning‐Assisted Process Optimization for High‐Performance Organic Thermoelectrics, Advanced Energy Materials (2024). DOI: 10.1002/aenm.202403431

Provided by

Seoul National University

Citation:

AI-driven design optimizes organic thermoelectric device performance (2024, December 5)