Kirigami is the Japanese art of paper cutting. Likely derived from the Chinese art of jiǎnzhǐ, it emerged around the 7th century in Japan, where it was used to decorate temples. Still in practice today, the kirigami artist uses one piece of paper to cut decorative designs, like birds and fish or the more intricate and popular snowflake.

But, this ancient art, which relies on exacting cuts to determine or replicate patterns, is finding more modern and practical applications in electronics. Specifically, in the manufacture of 2D stretchable materials that can play host to wearable electronics, like electronic skins for health monitoring.

The process combines the art of kirigami with an artificial intelligence technique called autonomous reinforcement learning. And to better synchronize the old with the new, researchers from the University of Southern California use the computing power available to them at the U.S. Department of Energy’s (DOE) Argonne National Laboratory.

Reinforcement learning relates to learning actions that impart a reward or specific outcome. For example, through a combination of observation, repetition and innate ability, a baby giraffe learns to stand, walk and even run on the day it is born. This helps it find food and avoid danger very quickly.

“This is complex planning, it’s learning,” says Pankaj Rajak, a lead member of this project and a former postdoc at the Argonne Leadership Computing Facility (ALCF), a DOE Office of Science user facility. “The question is, can we use a similar behavior in materials design, like in this kirigami, where your objective is to create a more structured material that is highly stretchable, one cut at a time. It’s a smart strategy for figuring out where the cuts should go.”

The researchers set out to create a 2D molybdenum disulfide structure embedded with electronics, like a semiconductor device, that can stretch but remain stable.

Experimental scientists found that a deliberate series of exacting cuts would allow the atomically thin material to stretch considerably, upwards of 40%. But, there were a lot of possible combinations of cuts. So, what information did the AI program need to know to get the right combinations?

To provide the program with some starting data—like the environmental observations of a giraffe—Rajak conducted 98,500 simulations that consisted of a range of one to six cuts with different lengths that determined stretchability.

The team produced their simulations on the ALCF supercomputer Theta, completing them in several months.

“You could have two hundred people each doing five experiments a day for one month collecting the data on different cuts,” notes team member Priya Vashishta. “It would be very expensive for material and for time. But in this case, the model was reasonably good and produced data that was very similar to experimental data.”

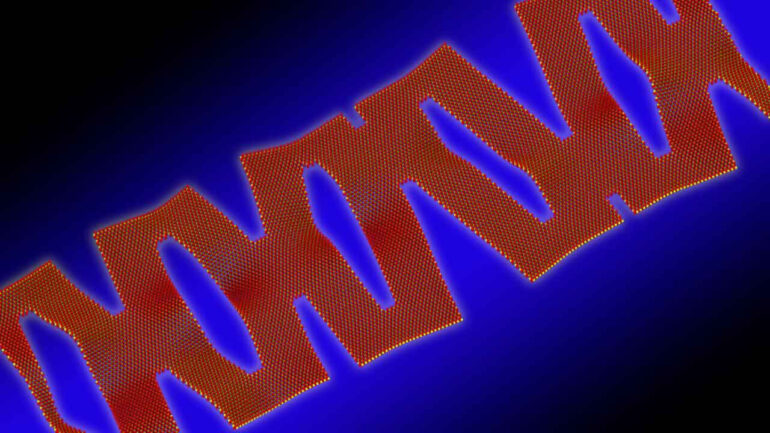

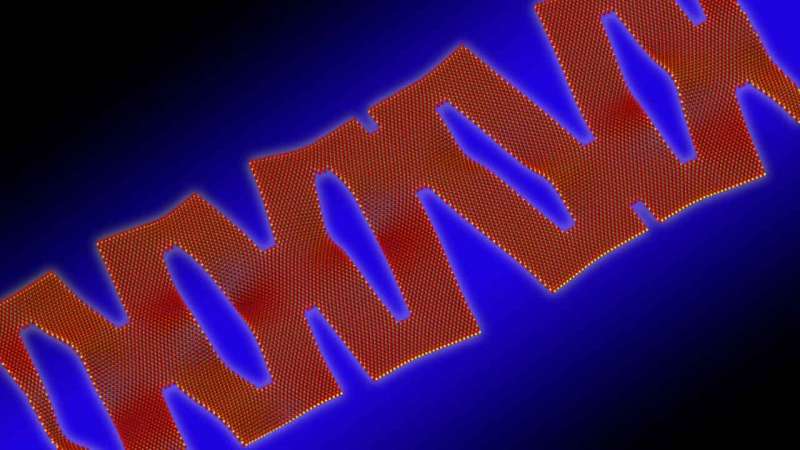

Stretching of atomically thin kirigami made of molybdenum disulfide, which was designed by reinforcement learning and simulated by molecular dynamics. © Ken-ichi Nomura and Pankaj Rajak, University of Southern California

After the model learned kirigami design strategies from the smaller number of cuts, researchers used it to create eight and 10 cuts, producing a combination of possible stretches and cuts that numbered around a billion.

“And if it took few months to do 98,500 simulations and you go three orders of magnitude higher, that is a lifetime,” Vashishta calculates.

But without any additional training data, the model was able to create a structure of 10 cuts exceeding 40% stretchability, on its own. And more astonishing, it only took a couple of seconds to produce.

“So, it has figured out things we never told it to figure out,” says Rajak. “It learned something the way a human learns and used its knowledge to do something different.”

So far, the work has served as a test run to determine the potential for creating such a material. Determining strength and flexibility through this kirigami method is crucial for understanding how to print on electronics that will distort and stretch upwards of 50% when worn.

In a related study, the team also used reinforcement learning to grow the layer or sheet on to which the kirigami technique and the electronics are applied.

To make the cuts work as intended, the researchers need a perfect 2D material. In this case, the molybdenum disulfide. If done in a lab, experimenters adhere the compound of molybdenum and sulfur onto a substrate, or building block layer, through a process called chemical vapor deposition.

“They literally have knobs that they’re turning to apply pressure and temperature, which is a function of time,” says team member Aiichiro Nakano. “They rotate these knobs, adding or reducing a little bit of this or that to get the right schedule of temperature and gas pressure.”

If not done precisely, any defects in the sheet, like missing atoms or altered crystal structures, can completely change the electronic product’s performance.

“Like the kirigami cuts, we are modeling this process through simulation, but using the reinforcement learning to optimize the chemical vapor deposit schedule, this time,” adds Nakano.

The research mentioned above is derived from two articles that appear in npj Computational Materials, published July 9 and July 12, 2021, respectively: “Autonomous reinforcement learning agent for stretchable kirigami design of 2D materials,” and “Autonomous reinforcement learning agent for chemical vapor deposition synthesis of quantum materials.”

More information:

Pankaj Rajak et al, Autonomous reinforcement learning agent for stretchable kirigami design of 2D materials, npj Computational Materials (2021). DOI: 10.1038/s41524-021-00572-y

Pankaj Rajak et al, Autonomous reinforcement learning agent for chemical vapor deposition synthesis of quantum materials, npj Computational Materials (2021). DOI: 10.1038/s41524-021-00535-3

Provided by

Argonne National Laboratory

Citation:

Ancient art of kirigami meets AI for better materials design (2022, April 8)