A team of South Korean researchers has developed an innovative haptic (tactile) display technology that is attracting global attention. This innovation allows users to physically experience 3D shapes and various textures, opening up potential applications in information delivery devices for the visually impaired, vehicle interfaces, metaverse applications, educational tools, and more.

Electronics and Telecommunications Research Institute (ETRI) announced the development of a display technology that generates three-dimensional tactile sensations using a photo-thermal elastic variable film. The results of this research were published in Nature Communications on March 22nd and were selected as a featured article.

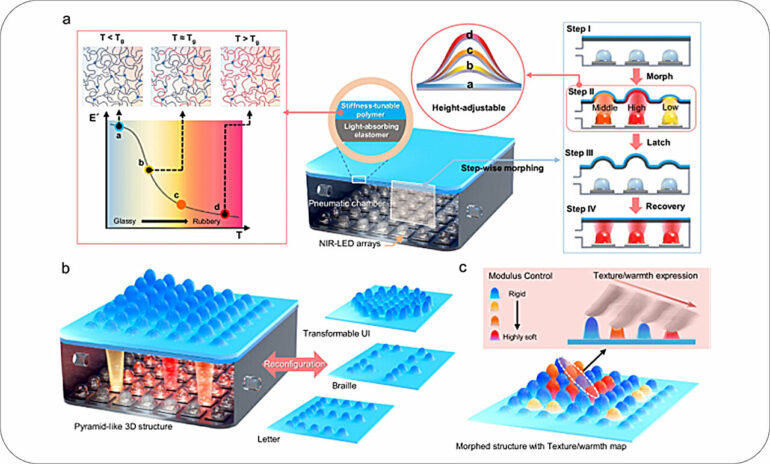

This technology uses infrared light-emitting diodes (LEDs) to adjust the intensity of light, enabling precise control of the height and elasticity of tactile elements with sizes of several millimeters (mm) on a smooth film surface.

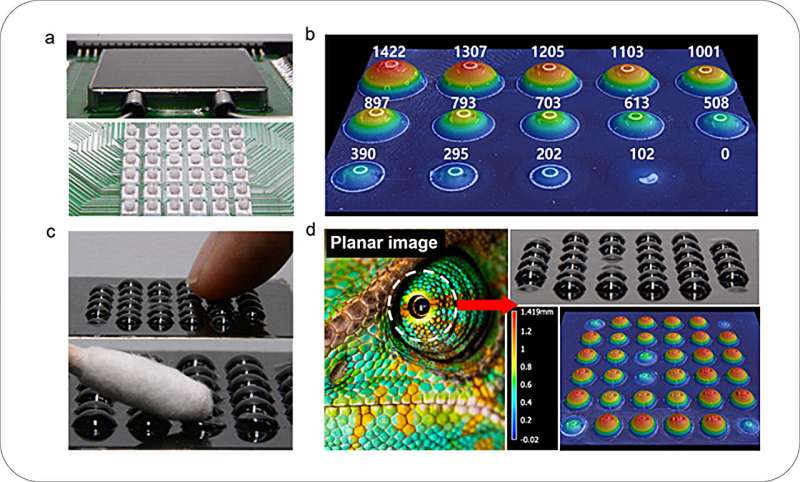

The tactile display developed by ETRI can directly represent braille, text, and various three-dimensional shapes. The key differentiator is its ability to finely control elasticity and temperature for different sections, accurately reproducing varying heights and textures.

The core of this technology lies in a functional polymer film structure composed of two thin layers, as thin as a strand of hair. The lower photo-thermal layer, facing the LED, absorbs light and generates heat. The upper variable elastic layer is hard at room temperature but becomes very soft when the heat from the photo-thermal layer causes it to undergo a glass-to-rubber transition at around 50 degrees Celsius.

3D Shape and Elasticity Representation by the Tactile Display. © Electronics and Telecommunications Research Institute(ETRI)

In this state, applying air pressure underneath the film causes it to swell according to the amount of heat absorbed, creating a tactile 3D shape. The maximum height of the 3D shape produced by a 4mm diameter element is 1.4mm, about twice that of a typical braille display, and can be finely controlled in 0.1mm increments based on the intensity of the LED light.

Notably, when the light is turned off, the upper layer cools and hardens again, allowing the shape to withstand touch without consuming additional power.

The research team focused on developing 3D elements based on light-responsive thermoelastic variable materials and a sensory perception model for 3D deformation.

Inwook Hwang, who is the first author of the paper and also ETRI’s principal researcher, explained, “Conventional braille tactile displays could only express simple shapes and had fixed heights. Our new technology allows each cell’s height and elasticity to be freely controlled, enabling the creation of realistic 3D terrains and textures.”

Sungryul Yun, the director of the Tangible Interface Creative Research Section at ETRI, added, “This innovative achievement elevates tactile display technology to a higher level. We plan to integrate large-area light sources and tiling technologies to expand to large 3D displays while enhancing cell resolution and maximizing energy efficiency.”

This technology has the potential to enable advanced 3D information delivery for the visually impaired, adaptive user interfaces in vehicles, tactile communication, and realistic educational models, making immersive tactile interaction a reality.

More information:

Inwook Hwang et al, Height-renderable morphable tactile display enabled by programmable modulation of local stiffness in photothermally active polymer, Nature Communications (2024). DOI: 10.1038/s41467-024-46709-7

Provided by

National Research Council of Science and Technology

Citation:

Creating 3D shapes from a flat surface using LEDs (2024, June 26)