Researchers at the Faculty of Science and Technology of Universidade de Coimbra (FCTUC) and Carnegie Mellon University have developed a water-based conductive ink tailored for producing flexible electronic circuits.

The technique, developed with Carnegie Mellon Portugal Program’s (CMU Portugal) support, sidesteps the necessity of employing conventional organic solvents, renowned for their detrimental environmental impact due to pollution and toxicity. The results have been published in the journal Advanced Science.

By being water-based, this ink is more sustainable and ecological and significantly reduces the environmental impact of existing solutions. On-skin bio stickers to monitor patients’ health or recyclable smart packages with integrated sensors for monitoring the safe storage of perishable foods are among the possible uses.

Manuel Reis Carneiro, a doctoral student from the CMU Portugal, is part of the team led by Mahmoud Tavakoli, which already has extensive experience developing stretchable electronic circuits efficiently, quickly, and cheaply.

They are now taking a new step by creating an ink that is sustainable and eco-friendly. Manuel Reis Carneiro explains, “Using a water-based ink for printing and producing flexible electronic circuits brings numerous advantages. On the one hand, it radically reduces the ecological footprint of production because it does not use polluting materials. On the other, it makes recycling and subsequent reuse of circuits much easier, which previously consisted of a complex procedure. Here, it is enough to place the circuit in alcohol. The components and metallic particles separate and are ready to be reused.”

Unlike its predecessors, this innovative ink does not require refrigeration, facilitating storage and markedly reducing ecological footprints and maintenance costs. These advancements hold transformative potential in the medical and food industries.

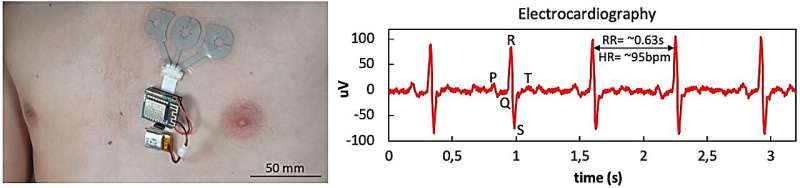

In health care, biomonitoring sensors and stickers can capture patient data like muscle activity, breathing, body temperature, heartbeat, brain activity, and emotions. The advent of this ink, enabling easy and affordable recycling, is especially impactful in combating electronic waste (e-waste) generated by single-use medical devices.

Electrophysiology patch adhered to the user’schest, over the sternal portion of the left pectoralis major muscle, connected to a biopotential recording system and battery. © ISR – FCTUC

This innovation finds its place in the food industry’s next era of smart packaging. Applying this ink on plastic-based sensors affixed to packages of perishable goods enables real-time temperature monitoring, guaranteeing preservation and quality assurance. This approach empowers consumers by identifying storage issues and informing decisions.

Manuel Reis adds, “These ‘smart stickers’ currently incorporate a temperature sensor that alerts users to contamination risks. The solution’s low production cost foreshadows future inclusion in perishable goods packaging to assure quality. While the focus is presently on temperature and exposure to unfavorable conditions, in the future, we hope to be able to monitor other factors such as pressure, humidity, position, or location.”

These advancements exemplify the development of sustainable solutions, marrying technology and environmental consciousness. As the world leans into electronics, merging functionality and environmental stewardship emerges as a beacon of progress.

More information:

Manuel Reis Carneiro et al, Recyclable Thin‐Film Soft Electronics for Smart Packaging and E‐Skins, Advanced Science (2023). DOI: 10.1002/advs.202301673

Provided by

Carnegie Mellon University

Citation:

Eco-friendly conductive ink promises to revolutionize the production of soft stretchable electronic circuits (2023, September 6)