Scientists from the Division of Mechanical Science and Engineering at Kanazawa University developed a prototype pipe maintenance robot that can unclog and repair pipes with a wide range of diameters. Using a cutting tool with multiple degrees of freedom, the machine is capable of manipulating and dissecting objects for removal. This work may be a significant step forward for the field of sewerage maintenance robots.

Various sewer pipes that are essential to the services of buildings require regular inspection, repair, and maintenance. Current robots that move inside pipes are primarily designed only for visual surveying or inspection. Some robots were developed for maintenance, but they couldn’t execute complicated tasks. In-pipe robots that can also clear blockages or perform complex maintenance tasks are highly desirable, especially for pipes that are too narrow for humans to traverse. Now, a team of researchers at Kanazawa University have developed and tested a prototype with these capabilities. “Our robot can help civic and industrial workers by making their job much safer. It can operate in small pipes that humans either cannot access or are dangerous,” explains first author Thaelasutt Tugeumwolachot.

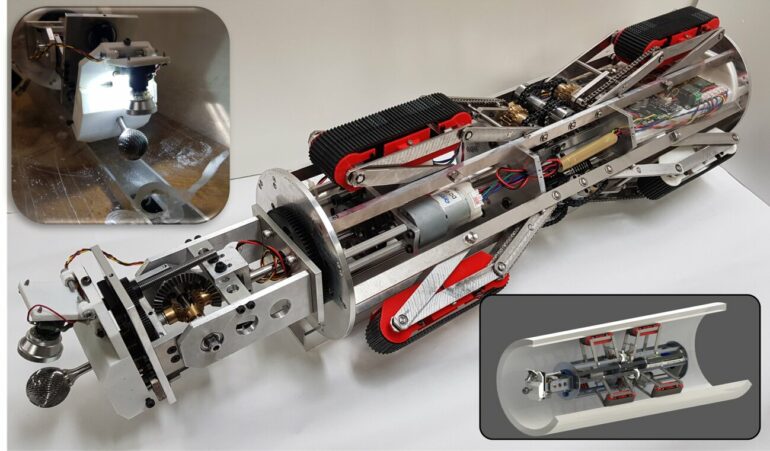

One of the main challenges with designing a robot of this kind is how to achieve a snug fit inside pipes of different sizes. Previous models can expand or contract their width by only about 60 percent. Here, the researchers used six foldable “crawler” arms around the body of the robot. This adjustable locomotion mechanism allowed it to work in pipes with sizes between 15 to 31 cm, a range of over 100 percent. Another design challenge is how to crowd complex and tough arm mechanism into small space. This robot equipped a compact arm which enables complicated cutting movements by being driven via gear train from several motors inside the robot body.

Municipal sewer systems today are often blocked by large, hard deposits colloquially called “fatbergs.” These are amalgams of materials such as flushable wipes, oil, and fat that have undergone a chemical process of saponification that makes them very difficult to remove. The team tested the robot’s ability to deal with such challenges by simulating blockages caused by fatbergs or other common blockages, such as tree branches. “We found that a cutting tool with a ball-shape burr was capable of accomplishing all of the pushing, cutting, drilling, and grinding tasks,” the team leader Hiroaki Seki says. The team expects that this research will lead to an increase in the use of robots for many difficult and dangerous jobs in narrow pipes.

More information:

Thaelasutt Tugeumwolachot et al, Development of a compact sewerage robot with multi-DOF cutting tool, Artificial Life and Robotics (2021). DOI: 10.1007/s10015-021-00694-y

Provided by

Kanazawa University

Citation:

Engineers build in-pipe sewer robot (2021, December 8)