Engineers at Princeton University are deploying lasers to precisely evaluate a major drawback of 3D-printed cement—the material’s resistance to fracture. The researchers hope that progress in this area could lead to a wider use of additive manufacturing in cement-based structures. The long-term goal is to develop better materials using additive techniques that lead to innovative designs and functions.

Cement is the major ingredient in the concrete that makes up much of modern construction—including buildings, roads, runways, bridges and dams. In recent years, as 3D printing has demonstrated advantages in efficiency and versatility, there has been a growing interest in applying the technology to construction.

But compared to conventionally cast concrete, the 3D-printed alternatives can be subject to cracking, particularly in areas between different layers of concrete. Researchers attribute this to non-uniform microstructures introduced by the layering process used in 3D printing. Princeton researchers have used a new test to better understand this cracking at a microscopic level. Their findings suggest that by properly characterizing the fracturing properties, 3D-printed concrete could be just as strong or even stronger than cast concrete.

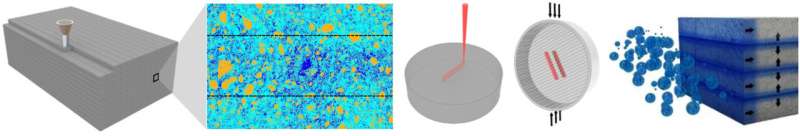

In a study in the journal Cement and Concrete Composites, Princeton researchers demonstrate a new testing method that uses lasers to cut precisely located grooves in 3D-printed cements. By controlling the power and speed of the laser, the researchers can control critical features such as the grooves’ depth and shape. This control allows for far more accurate testing than conventional methods.

“We can now gain a more thorough understanding of the fracture properties of 3D-printed cement-based materials under various modes of failure, which is important for eventually scaling up this technology,” said Reza Moini, an assistant professor in the Department of Civil and Environmental Engineering at Princeton and senior author of the study. “There are new opportunities to make stronger and tougher materials by leveraging the design of materials architecture and fabrication freedom that comes with additive technologies.”

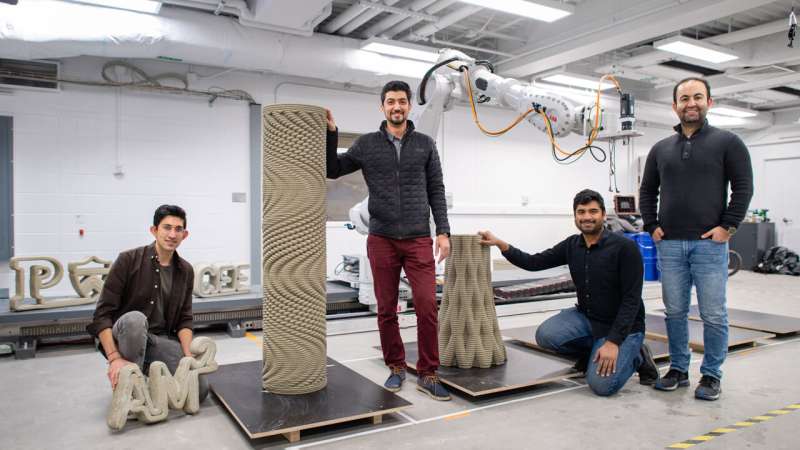

Princeton researchers work to improve the use of additive manufacturing for concrete and other cement-based materials. The research team, from left to right, Arjun Prihar, Reza Moini, Shashank Gupta, and Hadi Esmaeeli. © Sameer Khan/Fotobuddy

The study’s other Princeton authors, all members of Moini’s lab, are Shashank Gupta and Arjun Prihar, both Ph.D. students, and Hadi Esmaeeli, a former associate research scholar.

Unlike cast concrete, which is poured into a form and hardened, 3D-printed concrete involves a nozzle that extrudes a cement paste one strand at a time. The nozzle moves back and forth, building up the concrete strand by strand and eventually layer by layer.

One challenge is that during extrusion, a thin, water-rich film tends to form around each printed strand to facilitate flow. Those water-rich films can lead to significant internal flaws and heterogeneities between strands of the 3D-printed material, contributing to structural weakness.

The Princeton researchers examined these interfaces in more detail to understand their relationship with fracture properties. The research team initially fabricated and cured samples for testing using a customized 3D printer that extruded cement paste. Traditional testing usually involves cutting notches into the material, often with circular saws. For studying the microstructures, though, those saws can act as blunt instruments often leading to non-sharp notches. This can make testing difficult and imprecise.

Instead of using a physical tool such as a saw to cut notches, Moini and colleagues opted to use a laboratory laser. Their approach cuts testing notches right to where it is needed, for instance at the interface between the printed layers.

Graphical abstract. © Cement and Concrete Composites (2023). DOI: 10.1016/j.cemconcomp.2023.105034

“The advantage of this test for brittle 3D-printed materials is that using the same sample geometry, one can capture the resistance to cracking under tension, shear, or any combination of the two,” Moini said.

Shashank Gupta, the paper’s first author, emphasized that “this approach can help inform the material properties as researchers are working with industry to scale up concrete additive manufacturing processes for structural and nonstructural applications.”

Graduate students in Moini’s lab are furthering these ends, investigating architected materials and fracture characteristics. Recently, at the spring convention of the American Concrete Institute in San Francisco in April, paper co-author Arjun Prihar won a third-place poster award and graduate student Krystal Delnoce won first place. Prihar’s research has focused on understanding the fracture mechanics of sinusoidally architected designs of concrete materials using experiment and simulation. Delnoce’s research has focused on adapting a new fracture test method for 3D-printed materials by developing a notch within the toolpath.

“Our work is helping to solve fundamental questions about the fracture behavior of 3D-printed concrete,” said Moini.

More information:

Shashank Gupta et al, Fracture and transport analysis of heterogeneous 3D-Printed lamellar cementitious materials, Cement and Concrete Composites (2023). DOI: 10.1016/j.cemconcomp.2023.105034

Provided by

Princeton University

Citation:

Lasers pave the way to better use of cement (2023, June 6)