A research team headed by Prof. Karl Leo at TUD Dresden University of Technology have developed an innovative, nature-inspired solution that could revolutionize the electronics industry: “Leaftronics.” This innovative approach leverages the natural structure of leaves to create biodegradable electronic substrates with enhanced properties and offers a sustainable, efficient, and scalable solution to the global-waste problem. These findings have now been published in the journal Science Advances.

Electronic devices, from toys to smartphones, consist of circuits. Specific substrates are used to manufacture these circuits. In commercial electronics, these are printed circuit boards (PCBs) made of glass fiber-reinforced epoxy resin.

Most of these materials are not recyclable, let alone biodegradable. Given the sheer volume of electronic waste of more than 60 million tons per year (of which over 75% is not collected worldwide), there is an urgent need for sustainable alternatives.

Previous research has focused on creating biodegradable natural polymers as materials, but these have faced problems with heat stability and resistance to chemicals. The inherent conflict between biodegradability, which requires loosely bound molecules and thermal or chemical stability, which demands tightly bound molecules, has long posed a significant challenge.

Now, a team of researchers at the Institute for Applied Physics at TUD Dresden University of Technology, led by Professor Karl Leo, has taken a major step forward by developing “Leaftronics”—an approach that leverages the natural structure of leaves to create biodegradable electronic substrates with enhanced properties. Their findings offer a sustainable, efficient, and scalable solution to the global e-waste problem.

Nature-inspired innovation: Quasi-fractals from leaves

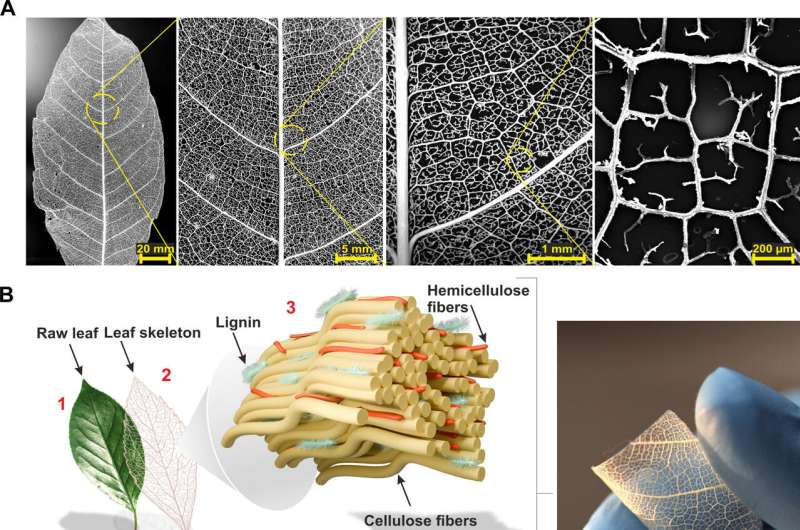

The breakthrough stems from the discovery that quasi-fractal lignocellulose structures in natural leaves, which serve as a scaffold for a leaf’s living cells, can be adapted to reinforce biodegradable solution-processed polymer films.

“We were surprised to find that these natural quasi-fractal lignocellulose skeletons not only support living cells in nature, but can also hold solution-processable polymers together, even at relatively high temperatures where these polymers should begin flowing,” explains Dr. Hans Kleemann, leader of the group Organic Devices and Systems at the Institute for Applied Physics.

Lignocellulose quasi-fractals and their coating. © Science Advances (2024). DOI: 10.1126/sciadv.adq3276

The discovery stems from the work done by Dr. Rakesh R. Nair, who performed research into implementing natural structures for state-of-the-art electronic applications for his recently concluded Ph.D.

“What we see is that the embedded, natural quasi-fractal structure seems to thermomechanically stabilize polymer films without compromising their biodegradability,” adds Nair.

The researchers have demonstrated that these lignocellulose-reinforced polymer films can withstand the manufacturing process for soldered circuitry and can support state-of-the-art thin-film devices like organic light-emitting diodes (OLEDs). The smoothness of the films, a key requirement for the deposition of ultra-thin layers of materials, opens the door for high-performance thin-film electronics to be fabricated on these substrates.

The promise of ‘Leaftronics’

Leaftronics represents a new paradigm in electronic materials, where biological structures are used to enhance the properties of polymers without the need for chemically intensive modifications. In addition to their technical advantages, these substrates have a carbon footprint three times lower than paper.

Once the devices have reached the end of their life cycle, the substrates can be easily decomposed in soil or processed in biogas plants, allowing for extraction of electronic components or precious materials for recycling purposes.

A sustainable future for electronics

The development of Leaftronics could have far-reaching implications for industries ranging from consumer electronics to renewable energy. As the global push for greener technologies intensifies, Leaftronics provides a glimpse into the future of electronics—where high-performance devices can coexist with environmental sustainability.

“This work points to a promising fusion of nature and technology, offering a sustainable path forward as we strive to reduce waste and combat climate change, a step to circular economy in electronics,” says Karl Leo, professor of optoelectronics and director of the interdisciplinary center Dresden Integrated Center for Applied Physics and Photonic Materials (DC IAPP).

More information:

Rakesh R. Nair et al, Leaftronics: Natural lignocellulose scaffolds for sustainable electronics, Science Advances (2024). DOI: 10.1126/sciadv.adq3276

Provided by

Dresden University of Technology

Citation:

Inspired by nature: Leaftronics pave way for biodegradable electronics (2024, November 26)