deepSPACE isn’t a futuristic film, a new videogame or the next season of a classic TV series. In fact, the new design software developed by an aerospace engineer at the University of Illinois at Urbana-Champaign isn’t about outer space at all. This new tool takes your concept and requirements and rapidly generates design configurations from conventional to out-of-this-world, including a 3D CAD model and performance evaluations.

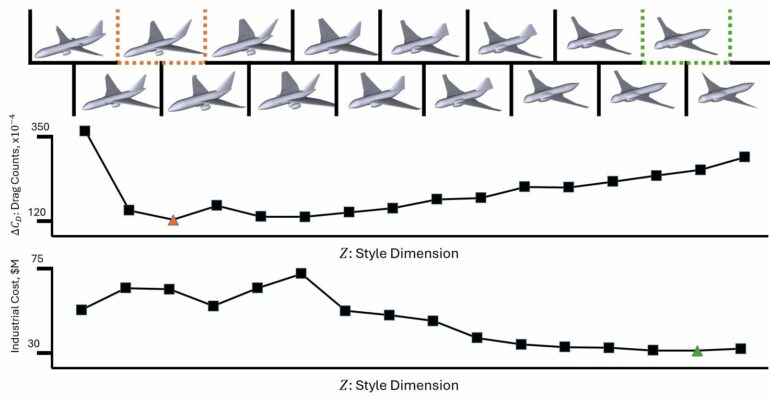

“We wanted to do for engineering and design what large AI language models have done for text,” said Jordan Smart. “Right now, when you open up engineering design software, you’re greeted with a blank screen. With deepSPACE, you tell it your requirements and it generates 100 to 1,000 concepts that are feasible within the time it would take a human to look at one or two. It gives you a much better picture of the broader design space.”

And Smart said deepSPACE isn’t limited to just physics-related questions: “It’s trained on a mix of historical and simulation data but can use standard cost estimation tools and get at least that level of feedback for a cost analysis.”

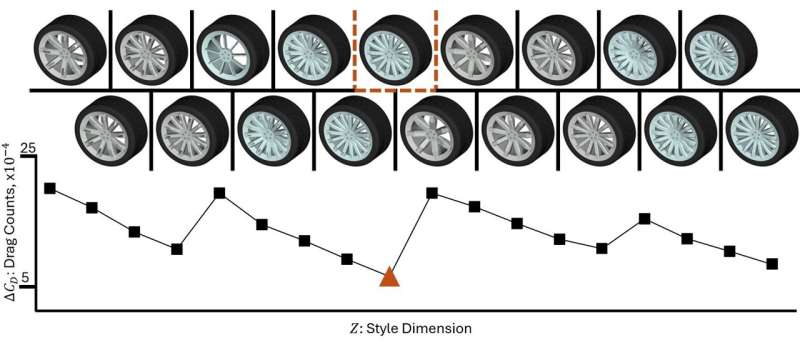

To demonstrate its flexibility, Smart and his research partner Emilio Botero used deepSPACE to generate physical system designs on beams, wheels, and aircraft but also on operational logistics networks. They created partnerships with large aircraft and automotive companies to ensure deepSPACE is something useful to researchers and industry professionals.

The research is published in the AIAA AVIATION FORUM AND ASCEND 2024.

“We learned that although individuals may want deepSPACE to come fully loaded, companies prefer to build custom models tied to their own data and knowledge. On the back end, we can build up our own models to use for research or design, but it can also be used beginning with zero data. It’s a teachable platform,” explained Smart.

According to Smart, deepSPACE is more efficient than older optimization algorithms. “Where others said they took 20,000 simulations to start to parameterize their design space, we were able to get similar results with only about 250 samples. So, with about 100 times fewer data points, you can get a real sense of the trade-offs in the design space.

“When you design an airplane and want to know what effect modifying the wing, adding an engine, or increasing the payload might have on the design, those sorts of sensitivities and trade-offs are complicated. Traditional methods can take thousands of different design points before they can reasonably interpolate between them. Because deepSPACE is building a complete generative model, it’s able to interpolate much more successfully on fewer data points. We’re able to make the same level of prediction with the same level of accuracy faster and more economically.”

The lower cost makes deepSPACE particularly valuable in aerospace applications. “We rely on simulation because building aircraft is expensive. But we’re looking at how it can be used in other industries,” Smart added.

The fact that deepSPACE provides a 3D CAD file is an added feature. Smart said the output from other image generating programs can’t be opened and used with other design software with all of its layers and effects still intact.

“With deepSPACE, you get exactly the same kind of raw file as if a human made it. So, any kind of edits or changes that you would want to do are there and available. It just slots right into your workflow as if you had subcontracted the work out to another firm and this was one of their deliverables.”

This example demonstrates deepSPACE’s ability to perform aerodynamic optimization of automotive rims. These rims are subject to cost and weight requirements. © University of Illinois at Urbana-Champaign

Smart said deepSPACE can create a unique design conversation with the human engineers that train it. Smart explained, “One of the designs that deepSPACE generated, we thought was absurd. We said, ‘Clearly something is wrong. It was designed to a set of requirements but nothing like this was in the training data.’ But then when we looked at the results, the actual simulation results for what it generated looked reasonable and met the requirements.”

The aircraft in question had relatively short wings with the control surfaces offset at the back to provide balance and stability. Smart said it wasn’t exploiting the simulation or doing something that couldn’t be built, so they started looking at it more closely and realized they’d seen something like it somewhere. Eventually, they found that it was similar to an actual airplane built and flown by a leading aircraft manufacturer.

“I had set up the training data, the simulation and the actual learning algorithm. We gave deepSPACE a learning set from three conventional tube and wing aircraft, the Concorde and one blended wing body concept. From that, it started generating its own concepts and checking them against the simulation and learning. Sometimes it would generate something nonphysical, but from that it learned where the edges are.

“Without a human saying ‘don’t consider this or that,’ it was able to run its own experimentation, like brainstorming, and find something that we didn’t expect. My personal bias would have said throw it out,” said Smart.

Smart said deepSPACE was able to show him the simulation results and how the design met his requirements. It found a viable solution to the problem, just as it was designed to do.

“We gave it a tabulated set of historical data, from which it augments its understanding and starts to explore and experiment. I can build up a baseline model to get the results, but then I can treat it like a playground or a sandbox. I can run a new simulation that isn’t in the historical data, see how that adds to my database of knowledge.

“For years, I’ve felt like we have incredible analysis capability, but the bottleneck has become us. We have simulations, but a human just can’t run thousands of simulations over and over and reject the bad ones and find the good ones and build that kind of intuition. deepSPACE is the first generation of systems designed to be like an engineer in your pocket. You can set up the problem and come back later to find a host of different options. Then, you can take it from there, and go farther with much more insight from the capabilities you already have.”

Although created with professional academic and industry professionals in mind, Smart has other ideas: “My goal is to get middle schoolers using something deepSPACE. They may not know the physics or have all of the skills to do a CAD drawing, but if they have an idea for a car, a train, a spaceship or something, they can tell deepSPACE about it and run it. Then they can make their own changes and see what happens next.”

More information:

Emilio M. Botero et al, DeepSPACE: Generative AI for Configuration Design Space Exploration, AIAA AVIATION FORUM AND ASCEND 2024 (2024). DOI: 10.2514/6.2024-4665

Provided by

University of Illinois at Urbana-Champaign

Citation:

New design software takes a concept to a multitude of configurations (2024, October 2)