This year has already seen massive heat waves around the globe, with cities in Mexico, India, Pakistan and Oman hitting temperatures near or past 50 degrees Celsius (122 degrees Fahrenheit).

As global temperatures and urban populations rise, the world’s cities have become “urban heat islands,” with tight-packed conditions and thermal radiation emitting from pavement and skyscrapers trapping and magnifying these temperatures. With 68% of all people predicted to live in cities by 2050, this is a growing, deadly problem.

In a paper publishedin Science, researchers from the UChicago Pritzker School of Molecular Engineering (PME) detail a new wearable fabric that can help urban residents survive the worst impacts of massive heat caused by global climate change, with applications in clothing, building and car design, and food storage.

In tests under the Arizona sun, the material kept 2.3 degrees Celsius (4.1 degrees Fahrenheit) cooler than the broadband emitter fabric used for outdoor endurance sports and 8.9 degrees Celsius (16 degrees Fahrenheit) cooler than the commercialized silk commonly used for shirts, dresses and other summer clothing.

This, the team hopes, will help many avoid the heat-related hospitalizations and deaths seen in global population centers this year alone.

“We need to reduce carbon emission and make our cities carbon negative or carbon neutral,” PME Asst. Prof. Po-Chun Hsu said. “But meanwhile, people are feeling the impact of these high temperatures.”

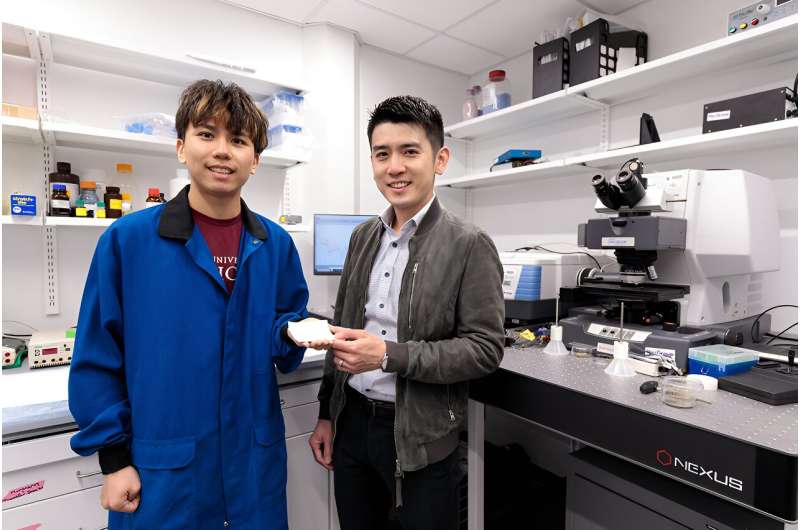

UChicago Pritzker School of Molecular Engineering Ph.D. candidate Chenxi Sui (left) and Asst. Prof. Po-Chun Hsu show off a sample of a new cooling textile that reflects both direct sunlight and the thermal radiation from pavement and buildings in urban heat islands. Their results, published in Science, show the material keeps 2.3 degrees Celsius (4.1 degrees Fahrenheit) cooler than outdoor endurance sports fabric and 8.9 degrees Celsius (16 degrees Fahrenheit) cooler than commercialized silk. © John Zich / UChicago Pritzker School of Molecular Engineering

‘You have to consider the environment’

Existing cooling fabric for outdoor sports works by reflecting the sun’s light in a diffuse pattern so it doesn’t blind onlookers. But in an urban heat island, the sun is only one source of heat. While the sun bakes from above, thermal radiation emitted from buildings and pavement blast city-dwellers with blistering heat from the sides and below.

This means many materials that perform well in lab tests won’t help city-dwellers in Arizona, Nevada, California, Southeast Asia and China when predicted massive heat waves hit them over the next few weeks.

“People normally focus on the performance or the material design of cooling textiles,” said co-first author Ronghui Wu, a postdoctoral researcher at PME. “To make a textile that has the potential to apply to real life, you have to consider the environment.”

One simple example of considering the environment is that people stand. They are wearing materials designed to reflect direct sunlight, but only their hats, shoulder coverings and the tops of their shoes—about 3% of their clothing—face that direct light. The other 97% of their clothes are being heated by the thermal radiation coming at them from the sides and below, which broadband emitter fabric does not fight.

The sun and sidewalk cook with different heats. Creating one material capable of protecting wearers from both provided a major engineering challenge for the team.

“Solar is visible light, thermal radiation is infrared, so they have different wavelengths. That means you need to have a material that has two optical properties at the same time. That’s very challenging to do,” said co-first author Chenxi Sui, a Ph.D. candidate at PME. “You need to play with material science to engineer and tune the material to give you different resonances at different wavelengths.”

Chenxi Sui and Ronghui Wu of the UChicago Pritzker School of Molecular Engineering, co-first authors of a new paper in Science, test their new radiative cooling fabric in Apache Junction, Arizona, in 2023. The team also tested the material in the urban heat islands of Chicago, Illinois. © Chenxi Sui / UChicago Pritzker School of Molecular Engineering

The costs of comfort

Cooling a home too often means warming the planet, with the carbon impact of air conditioning and refrigeration systems contributing to climate change.

“Our civilization actually uses about 10 to 15% of the energy in total just to make ourselves feel comfortable wherever we go,” Hsu said.

The risk from heat is not distributed evenly, however. In the U.S. and Japan, more than 90% of households have an air conditioner, a number that drops to 5% in India and parts of Africa.

The PME team’s new textile, which has received a provisional patent, can help provide a passive cooling system that can supplement and reduce the need for energy- and cost-intensive systems.

The applications go far beyond clothing.

A thicker version of the fabric protected by an invisible layer of polyethylene could be used on the sides of buildings or cars, lowering internal temperatures and reducing the cost and carbon impact of air conditioning. Similarly, the material could be used to transport and store milk and other foods that would otherwise spoil in the heat, cutting refrigeration’s impact.

“You can save a lot of cooling, electricity and energy costs because this is a passive process,” Sui said.

More information:

Ronghui Wu et al, Spectrally engineered textile for radiative cooling against urban heat islands, Science (2024). DOI: 10.1126/science.adl0653

Provided by

University of Chicago

Citation:

New fabric makes urban heat islands more bearable (2024, June 13)