By using new geometric shapes in shock-absorbing material, researchers at the Universities of Gothenburg and Isfahan have developed a bicycle helmet that provides better protection against head injuries. The material absorbs shock by contracting bilaterally.

The work is published in the International Journal of Solids and Structures.

Bicycle helmets are important for protecting cyclists from head injuries, but traditional designs have limitations in terms of impact absorption and fit.

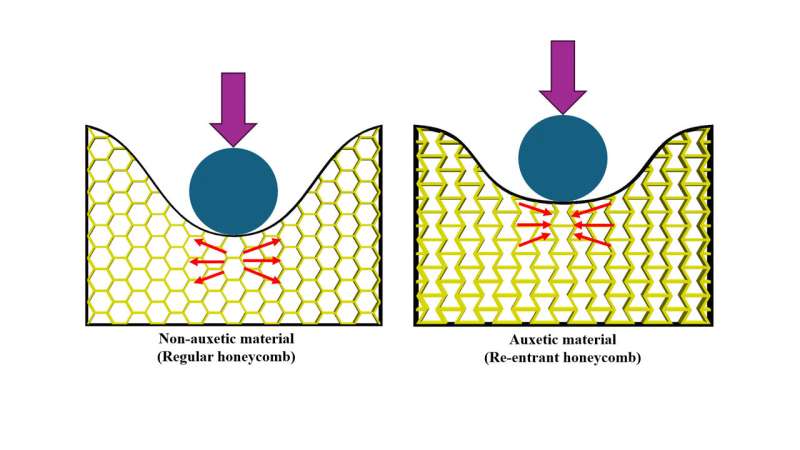

Researchers at the University of Gothenburg and the University of Isfahan in Iran designed a bicycle helmet whose shock-absorbing material utilizes what is called auxetic metastructures. The material is designed in special geometric patterns that behave differently under impact conditions compared to conventional foam liners.

“When exposed to energy from an impact, the liner material contracts, and this improves the absorption of impact energy, which means lower risks of injuries to a cyclist’s head in an accident,” says Mohsen Mirkhalaf, Associate Professor in the mechanics and physics of materials at the University of Gothenburg.

Geometry is key

The research study, published in the International Journal of Solids and Structures, combines what is known about auxetic metastructures with computer simulations and optimization techniques to develop a safer bicycle helmet.

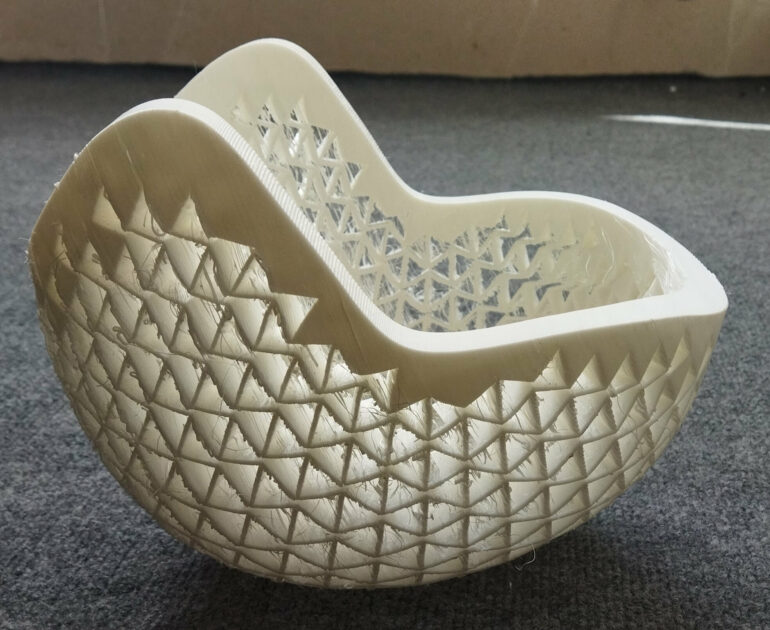

The shock-absorbing layer of a bicycle helmet has a geometric structure that absorbs crash forces better than today’s helmets. © Mohammad Hossein Zamani

“We used a specific design optimization method to identify the best possible geometric configuration to minimize crash forces. The geometry of the material structure is a key factor,” says Mirkhalaf.

Finally, the new helmet’s protective layer was printed on a 3D printer for testing. The material chosen was a plastic, a hyperelastic polymer, which can undergo significant deformations and return to its original shape. Standard tests on two different types of impacts against the new helmet show that it protects the head better.

Can be customized

“The knowledge of auxetic metastructures that expand laterally when stretched has been around for almost 40 years. However, development of different metastructures has exploded due to the advancements in 3D printing technology,” says Mirkhalaf.

Illustration how the auxetic structure absorbs the impact. © Ali Rahimi-Lenji, Mohammad Heidari-Rarani

Not only does the new helmet design provide better protection, but it is also lighter and the auxetic liner can be customized to individual head shapes using 3D printing. That is beneficial for professional athletes or people who have difficulty finding a comfortable helmet.

This research is a step towards smarter protective equipment, which could eventually be used not only in cycling but also in other areas that require protection against impacts.

“With further development, this technology could lead to a new generation of bicycle helmets that are safer, more comfortable and more customizable. Although 3D printing technology is currently more expensive than mass-produced foam liners, costs are expected to fall as the technology becomes more widely used.

“In the future, it may even be possible to have personalized helmets printed on demand, ensuring that each rider receives the best possible protection.”

More information:

Mohammad Hossein Zamani et al, Design, optimization and additive manufacturing of an innovative bike helmet using auxetic metastructures, International Journal of Solids and Structures (2025). DOI: 10.1016/j.ijsolstr.2025.113240

Provided by

University of Gothenburg

Citation:

New geometric design of material provides safer bicycle helmet (2025, March 25)