CCU (carbon capture and utilization), which captures CO2 and converts it into useful compounds, is crucial for rapidly transitioning to a carbon-neutral society. While CCS (carbon capture and storage), which only involves CO2 storage, has entered the initial commercialization stage due to its relatively simple process and low operational costs, CCU has only been explored at the research level due to the complexity of conversion processes and high production costs of compounds.

Dr. Lee Ung’s team at the Clean Energy Research Center of the Korea Institute of Science and Technology have developed a novel CCU process that converts CO2 into formic acid. Formic acid, an organic acid, is a high-value compound used in various industries such as leather, food, and pharmaceuticals.

The study is published in the journal Joule.

Currently formic acid retains a large market consuming around one million tons annually, which is expected to grow in the future owing to its potential use as a hydrogen carrier. Moreover, it has a higher production efficiency compared to other CCU-based chemicals, as it can be produced from a single CO2 molecule.

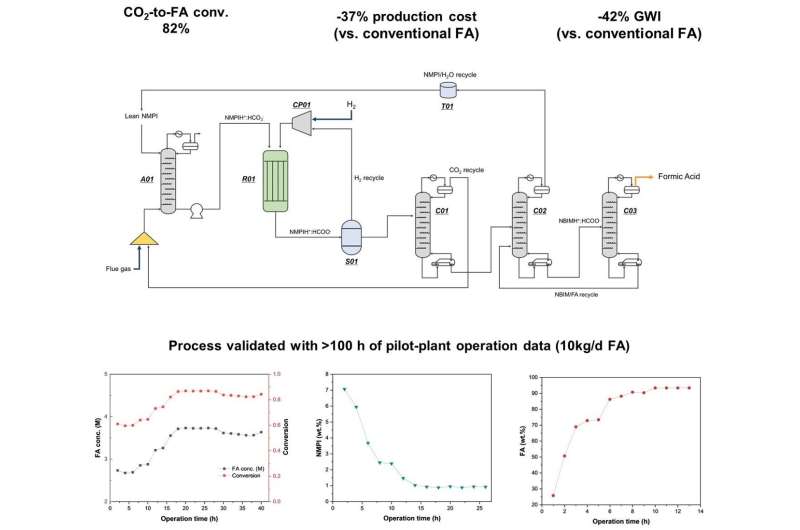

The research team selected 1-methylpyrrolidine, which exhibited the highest CO2 conversion rate among various amines mediating formic acid production reactions, and optimized the operating temperature and pressure of the reactor containing a ruthenium (Ru)-based catalyst, thereby increasing the CO2 conversion rate to over twice the current level of 38%.

To address the excessive energy consumption and formic acid decomposition issues during CO2 separation from air or exhaust gases and formic acid purification, the team developed a simultaneous capture-conversion process that directly converts CO2 captured within the amine without separating it.

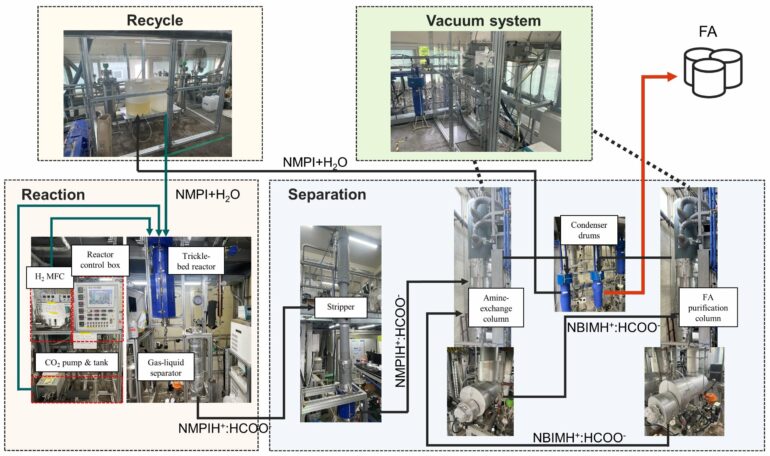

Flowchart of the process (above) for producing formic acid through the conversion of newly developed carbon dioxide (CO2) using Carbon Capture & Utilization (CCU), and pilot-scale process verification data (below). © Korea Institute of Science and Technology

As a result, they significantly reduced the formic acid production cost from around $790 per ton to $490 per ton while mitigating CO2 emissions, compared to conventional formic acid production.

To evaluate the commercialization potential of the developed formic acid production process, the research team constructed the world’s largest pilot plant capable of producing 10 kg of formic acid per day.

Previous CCU studies were conducted on a small scale in laboratories and did not consider the product purification process required for large-scale production. However, the research team developed processes and materials to minimize corrosion and formic acid decomposition, and optimized operating conditions that led to successful production of formic acid with a purity exceeding 92%.

The team plans to complete a 100 kg per day pilot plant by 2025 and conduct process verification, aiming for commercialization by 2030. Success in process verification with the 100 kg pilot plant is expected to enable transportation and sales to demand companies.

Dr. Lee Ung stated, “Through this research, we have confirmed the commercialization potential of our process that converts CO2 to formic acid, which is a huge breakthrough considering that most CCU technologies are being conducted at lab-scale.”

He further expressed his intention to contribute to achieving the country’s carbon neutrality goal by accelerating the commercialization of CCU.

More information:

Changsoo Kim et al, Accelerating the net-zero economy with CO2-hydrogenated formic acid production: Process development and pilot plant demonstration, Joule (2024). DOI: 10.1016/j.joule.2024.01.003

Provided by

National Research Council of Science and Technology

Citation:

New process brings commercialization of CO₂ utilization technology to produce formic acid one step closer (2024, May 7)