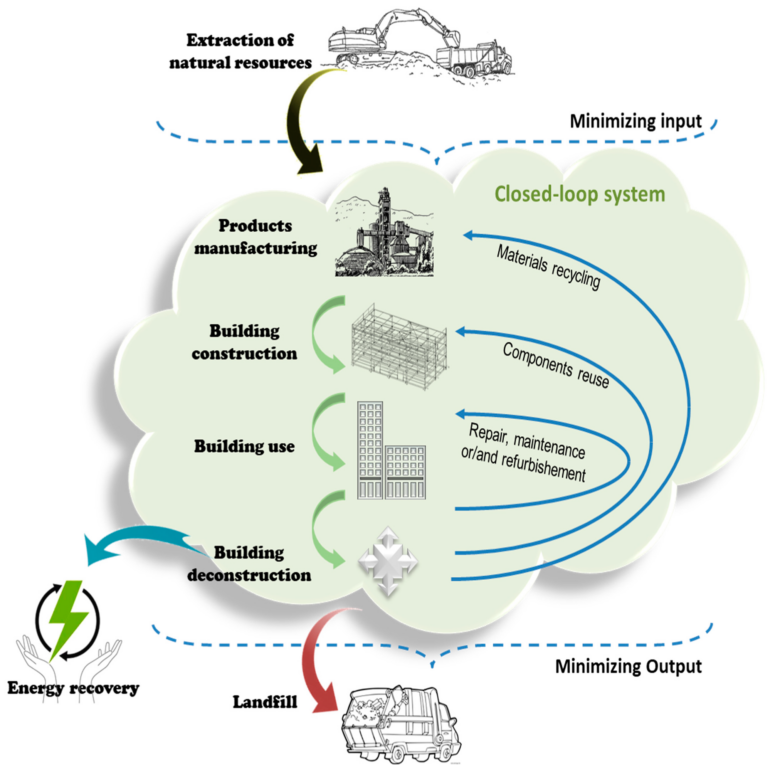

Building construction accounts for a huge chunk of greenhouse gas emissions: About 36% of carbon dioxide emissions and 40% of energy consumption in Europe, for instance. That’s why the European Union has developed regulations about the reuse of building materials.

Some cities are adding more material reuse into construction already. Amsterdam, for example, is attempting to slash its raw material use by half by 2030. The Netherlands as a whole aims for a circular economy of completely reused materials by 2050.

But the best way to organize the reuse of construction waste is still being determined. For one thing: Where should reusable building materials be stored before they are reused? A newly published study focusing on Amsterdam finds the optimal material reuse system for construction has many local storage hubs that keep materials within a few miles of where they will be needed.

“Our findings provide a starting point for policymakers in Amsterdam to strategize land use effectively,” says Tanya Tsui, a postdoc at MIT and a co-author of the new paper. “By identifying key locations repeatedly favored across various hub scenarios, we underscore the importance of prioritizing these areas for future circular economy endeavors in Amsterdam.”

The study adds to an emerging research area that connects climate change and urban planning.

“The issue is where you put material in between demolition and new construction,” says Fábio Duarte, a principal researcher at MIT’s Senseable City Lab and a co-author of the new paper. “It will have huge impacts in terms of transportation. So you have to define the best sites. Should there be only one? Should we hold materials across a wide number of sites? Or is there an optimal number, even if it changes over time? This is what we examined in the paper.”

The paper, “Spatial optimization of circular timber hubs,” is published in npj Urban Sustainability. The authors are Tsui, who is a postdoc at the MIT Senseable Amsterdam Lab in the Amsterdam Institute for Advanced Metropolitan Solutions (AMS); Titus Venverloo, a research fellow at MIT Senseable Amsterdam Lab and AMS; Tom Benson, a researcher at the Senseable City Lab; and Duarte, who is also a lecturer in MIT’s Department of Urban Studies and Planning and the MIT Center for Real Estate.

Numerous experts have previously studied at what scale the circular economy of reused materials might best operate. Some have suggested that very local circuits of materials recycling make the most sense; others have proposed that building-materials recycling will work best at a regional scale, with a radius of distribution covering 30 or more miles. Some analyses contend that global-scale reuse will be necessary to an extent.

The current study adds to this examination of the best geographic scale for using construction materials again. Currently the storage hubs that do exist for such reused materials are chosen by individual companies, but those locations might not be optimal either economically or environmentally.

To conduct the study, the researchers essentially conducted a series of simulations of the Amsterdam metropolitan area, focused exclusively on timber reuse. The simulations examined how the system would work if anywhere from one to 135 timber storage hubs existed in greater Amsterdam. The modeling accounted for numerous variables, such as emissions reductions, logistical factors, and even how changing supply-and-demand scenarios would affect the viability of the reuse hubs.

Ultimately, the research found that Amsterdam’s optimal system would have 29 timber hubs, each serving a radius of about 2 miles. That setup generated 95% of the maximum reduction in CO2 emissions, while retaining logistical and economic benefits.

That results also lands firmly on the side of having more localized networks for keeping construction materials in use.

“If we have demolition happening in certain sites, then we can project where the best spots around the city are to have these circular economy hubs, as we call them,” Duarte says. “It’s not only one big hub—or one hub per construction site.”

The study seeks to identify not only the optimal number of storage sites, but to identify where those sites might be.

“[We hope] our research sparks discussions regarding the location and scale of circular hubs,” Tsui says. “While much attention has been given to governance aspects of the circular economy in cities, our study demonstrates the potential of utilizing location data on materials to inform decisions in urban planning.”

The simulations also illuminated the dynamics of materials reuse. In scenarios where Amsterdam had from two to 20 timber recycling hubs, the costs involved lowered as the number of hubs increased—because having more hubs reduces transportation costs. But when the number of hubs went about 40, the system as a whole became more expensive—because each timber depot was not storing enough material to justify the land use.

As such, the results may be of interest to climate policymakers, urban planners, and business interests getting involved in implementing the circular economy in the construction industry.

“Ultimately,” Tsui says, “we envision our research catalyzing meaningful discussions and guiding policymakers toward more informed decisions in advancing the circular economy agenda in urban contexts.”

More information:

Tanya Tsui et al, Spatial optimization of circular timber hubs, npj Urban Sustainability (2024). DOI: 10.1038/s42949-024-00153-0

Provided by

Massachusetts Institute of Technology

Citation:

Optimal system for reusing construction materials includes local storage, a new study of Amsterdam suggests (2024, March 22)